Guide Contents

Project Insight: Cnc Screw Machine

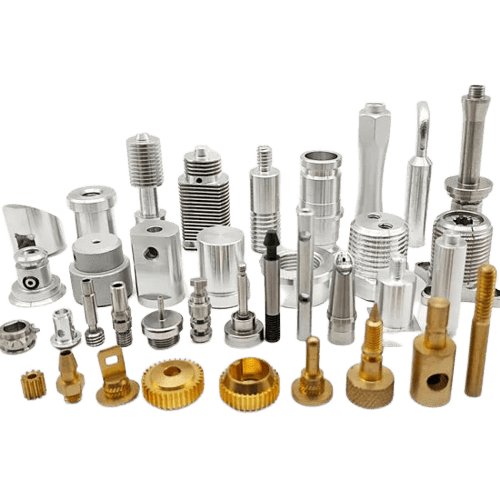

Manufacturing Insight: CNC Screw Machine – Precision Meets Speed in Product Development

In today’s fast-paced hardware innovation landscape, speed and precision are non-negotiable. For startups and engineers, even minor delays or tolerances outside specs can derail entire product launches. At Honyo Prototype, we combine cutting-edge CNC screw machine technology with digital agility to deliver micron-level accuracy and unmatched production speed—turning your designs into functional, market-ready parts faster than ever.

Why Speed and Precision Drive Innovation

Rapid Prototyping Cycles: Reduce time-to-market by up to 40% with same-day design validation and iterative testing—critical for startups iterating on complex mechanical designs.

Tight Tolerances for Critical Applications: Achieve ±0.01mm precision consistently, ensuring threaded components (e.g., 2-56 threads for micro fasteners) meet aerospace, medical, and IoT standards.

High-Volume Reliability: Produce 200K+ parts with zero variation in thread quality or dimensional accuracy—eliminating costly rework and scrap.

Honyo’s Digital Manufacturing Advantage

Online Instant Quote: Upload your CAD file and receive real-time pricing in seconds—no waiting for manual estimates. Our AI analyzes geometry, material, and volume to deliver transparent, optimized cost breakdowns.

AI-Optimized Production: Machine learning algorithms dynamically adjust toolpaths and cycle times, cutting costs by up to 25% while maintaining sub-micron precision.

72-Hour Fast Turnaround: From quote to delivery, our fully integrated workflow ensures high-precision parts ship within 3 days—keeping your project timeline on track.

“Precision isn’t just a specification—it’s the foundation of innovation. With Honyo, you’re not just ordering parts; you’re accelerating your product’s journey from concept to reality.”

— Susan Leo, Founder of Honyo Prototype

Whether prototyping miniature medical devices or scaling production of threaded components, Honyo Prototype delivers the speed, precision, and digital efficiency your hardware startup needs to outpace the competition.

Get your instant quote today →

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

At Honyo Prototype, we fuse cutting-edge CNC screw machine technology with intelligent automation to deliver precision-engineered parts that accelerate product development cycles. Our capabilities are engineered for hardware startups and product engineers who demand uncompromising accuracy, scalability, and speed—from concept to production.

Precision CNC Screw Machine Technology

3/4/5-axis machining for complex geometries and intricate details, enabling production of parts with unparalleled geometric versatility.

Tight tolerances of ±0.01mm to ensure functional performance in critical applications, from aerospace components to medical devices.

Optimized for high-precision functional prototypes and end-use parts, eliminating the need for secondary operations.

Scalable Production Capacity

Seamlessly handle projects from 1 prototype to 10,000+ production parts with zero workflow disruption.

Flexible manufacturing workflows tailored to your specific volume, timeline, and budget constraints.

Efficient cycle time management driven by AI-driven optimization, reducing costs without sacrificing quality.

AI-Powered Platform for Instant Quoting & Speed

Real-time online quotes with AI-driven design analysis and dynamic cost modeling for immediate transparency.

Automated Design for Manufacturability (DFM) feedback to eliminate rework, minimize material waste, and cut lead times by up to 30%.

24–48 hour prototype delivery with competitive production lead times, ensuring your product hits the market faster.

ISO-Certified Quality Assurance

Rigorous QC processes at every stage—from material inspection to final dimensional verification—ensuring consistency.

ISO 9001 certified quality management system guaranteeing traceability, compliance, and reliability for global standards.

Comprehensive inspection reports with full digital traceability for every part, empowering confident decision-making.

Engineered for innovation. Delivered at speed.

Materials & Surface Finishes

Material Options & Finishes for Precision CNC Screw Machining

At Honyo Prototype, material and finish selection is the cornerstone of delivering parts that balance functional performance, cost efficiency, and production scalability. Our expertise in high-precision CNC screw machining (±0.01mm tolerances) ensures your design translates seamlessly from concept to reality—whether for functional prototypes or end-use components. Leveraging AI-driven insights and optimized workflows, we eliminate guesswork and accelerate your time-to-market.

Material Selection Guide

Choose materials that align with your part’s mechanical demands, production volume, and cost targets. Screw machines excel at high-volume cylindrical parts with threading—here’s how our materials stack up:

Aluminum 6061:

Why choose it? Exceptional machinability, corrosion resistance, and cost-effectiveness. Ideal for high-speed screw machining of lightweight components (e.g., aerospace brackets, consumer electronics housings).

Best for: Prototypes, low-to-medium volume runs where weight and budget matter.

Aluminum 7075:

Why choose it? Superior strength-to-weight ratio (2x stronger than 6061) with good fatigue resistance. Requires precision tooling but delivers rugged performance.

Best for: High-stress applications like military hardware, racing components, and structural aerospace parts.

Stainless Steel 304:

Why choose it? Balanced corrosion resistance, non-magnetic properties, and ease of threading. Cost-efficient for general industrial use.

Best for: Food processing equipment, medical devices, and marine hardware where moderate corrosion resistance is needed.

Stainless Steel 316:

Why choose it? Enhanced chloride resistance (ideal for saline/chemical environments) and superior biocompatibility.

Best for: Marine components, surgical implants, and chemical processing systems requiring long-term durability.

Brass:

Why choose it? Ultra-fast machining speeds, excellent electrical conductivity, and natural lubricity. Perfect for threaded fasteners and connectors.

Best for: High-volume electrical contacts, valves, and decorative hardware where cycle time reduction is critical.

PEEK:

Why choose it? Extreme thermal stability (up to 250°C), chemical inertness, and lightweight properties. Requires specialized tooling but excels in demanding environments.

Best for: Aerospace seals, semiconductor components, and medical implants where polymers outperform metals.

Surface Finishes & Applications

Enhance part functionality, aesthetics, and longevity with precision finishes tailored to your material and use case:

Anodizing (Type II/III):

Benefits: Corrosion resistance, wear protection, and color options. Type III (hardcoat) adds 2–3x thickness for high-wear parts.

Ideal for: Aluminum components in outdoor, automotive, or aerospace applications.

Powder Coating:

Benefits: Durable, UV-resistant finish with vibrant colors and uniform coverage for complex geometries.

Ideal for: Consumer products, architectural hardware, and industrial enclosures requiring both protection and style.

Electroplating (Nickel/Chrome/Zinc):

Benefits: Hardened surface, improved conductivity, and corrosion resistance. Nickel for general use; chrome for decorative shine; zinc for cost-effective steel protection.

Ideal for: Brass/steel automotive parts, electrical connectors, and marine fittings.

Polishing (Mechanical/Electropolishing):

Benefits: Mirror-smooth surface finish, reduced friction, and enhanced hygiene. Electropolishing removes micro-imperfections for critical surfaces.

Ideal for: Medical devices, optical components, and food-grade equipment.

Passivation:

Benefits: Removes surface iron contaminants from stainless steel, boosting corrosion resistance without altering dimensions.

Ideal for: Surgical tools, chemical processing parts, and marine hardware.

Brushed Finish:

Benefits: Uniform matte texture that hides minor scratches and adds a premium aesthetic.

Ideal for: Consumer electronics, architectural panels, and luxury hardware.

Optimize Your Project with Honyo’s Digital Platform

Eliminate delays and guesswork with our AI-powered tools designed for speed and precision:

🚀 Online Instant Quote:

Upload your CAD file in seconds—get real-time pricing for materials, finishes, and quantities. No manual quotes, no waiting.

🤖 AI-Powered Material Recommendations:

Our intelligent system analyzes your design specs and application needs to suggest the optimal material and finish combo, balancing performance, cost, and manufacturability.

⏱️ Fast Turnaround:

Prototype to production in as little as 3 days. Our high-volume screw machines and streamlined workflows ensure you hit deadlines without compromising on ±0.01mm precision.

Partner with Honyo Prototype to transform your vision into reality—where innovation meets precision, and speed is never a compromise. Get Your Instant Quote Now

From Quote to Part: Our Process

How It Works: From CAD to Part

At Honyo Prototype, we’ve reimagined CNC screw machine manufacturing for modern hardware innovation. Our AI-driven workflow eliminates traditional bottlenecks, delivering precision-engineered parts with unmatched speed and transparency. Here’s how it works:

Step 1: Upload Your CAD File

Drag and drop your design files (STEP, IGES, STL) into our secure cloud platform—no software installation required.

Our system instantly validates your geometry for screw machine compatibility, flagging potential issues upfront (e.g., non-cylindrical features, thread complexity) to ensure seamless production.

Step 2: AI-Powered Instant Quote

Receive a real-time, transparent quote in seconds—no manual estimates or waiting days.

Our proprietary AI engine analyzes part geometry, material, quantity, and tolerances (+/- 0.01mm) to calculate precise costs, including cycle time optimization and material waste reduction.

See a clear breakdown: per-part pricing, setup fees, and volume discounts—no hidden charges.

Step 3: Automated DFM Analysis

Our intelligent Design for Manufacturability (DFM) engine identifies opportunities to streamline production (e.g., simplifying undercuts, optimizing thread paths) while preserving functionality.

Get actionable feedback to refine your design for screw machine efficiency—minimizing setups, maximizing throughput, and ensuring precision at scale.

Step 4: Precision Production & Swift Delivery

Leverage our high-speed screw machines and multi-axis capabilities to produce parts with micron-level accuracy, even for 50,000+ volumes.

Start production within 24 hours of approval; high-volume orders delivered in as little as 5 days from our Shenzhen facility.

Track your shipment in real-time with end-to-end visibility—from machine status to global delivery—via our customer portal.

💡 Why startups love this workflow:

– Zero guesswork: AI-driven insights cut prototyping costs by up to 30% through early DFM fixes.

– Scale effortlessly: From 100-unit prototypes to 500,000-piece runs, our platform adapts to your growth without rework.

– Global-ready: Shenzhen-based production ensures <10-day delivery to North America/Europe, with ISO 9001-certified quality control at every step.

Ready to transform your design into precision parts? [Upload your CAD file now]—let’s build the future, faster.

Start Your Project with Honyo

Start Your Project with Honyo

Precision Engineering, Simplified

Online Instant Quote

Upload your CAD file and receive an accurate, transparent quote in seconds—no manual back-and-forth. Our AI-driven platform analyzes geometry, tolerances, and material to optimize costs before you commit.

AI-Powered Manufacturing Insights

Automatically detect DFM (Design for Manufacturing) issues and get real-time suggestions to reduce rework, material waste, and cycle times—ensuring your design is production-ready from day one.

Fast Turnaround Guarantee

Prototype in 3 days, production in 7 days—our automated workflow delivers ±0.01mm precision at scale, whether you need 1 part or 200,000+ screw machine components.

Built for the Innovators You Are

Scalable Solutions

Seamlessly transition from prototype to high-volume production. Our 3/4/5-axis CNC capabilities handle complex geometries while maintaining tight tolerances—perfect for functional prototypes and end-use parts.

Cost-Optimized by Design

Avoid hidden fees. Our platform identifies savings in toolpath efficiency, material selection, and process optimization—so you pay only for what’s necessary, not for guesswork.

Global Standards, Local Expertise

Based in Shenzhen and Dongguan, we combine China’s manufacturing excellence with engineering rigor. Every part is built to meet ISO standards and your exact specifications.

Let’s Bring Your Vision to Life

Connect with Susan Leo & Our Team

Our founder and precision engineering experts are ready to collaborate—whether you’re solving a one-off challenge or scaling a full product line.

Reach Out Today:

📧 info@hy-proto.com

📞 +86 139 2843 8620

🌏 Visit our Shenzhen/Dongguan facilities for a virtual tour or in-person consultation.

Innovation starts with precision. Let’s build it together.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.