Contents

Manufacturing Insight: Cnc California

Manufacturing Insight: CNC California

CNC machining represents the cornerstone of precision manufacturing for California’s innovation-driven industries, from Silicon Valley tech startups to aerospace leaders in Southern California. At Shenzhen Honyo Prototype, we understand that California’s demanding ecosystem requires rapid iteration, uncompromising quality, and seamless integration with agile development cycles. Our advanced CNC capabilities bridge the gap between conceptual design and production-ready components, ensuring your prototypes and low-volume runs meet the rigorous standards expected in markets where performance and reliability are non-negotiable.

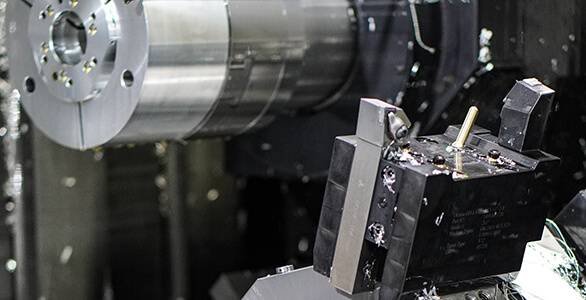

Modern CNC technology leverages computer-controlled subtractive processes to transform raw materials into complex geometries with micron-level accuracy. Honyo Prototype employs state-of-the-art 3-axis, 4-axis, and 5-axis simultaneous machining centers, enabling intricate features, tight tolerances, and optimized surface finishes critical for functional testing and end-use applications. Our process integrates CAD/CAM-driven toolpath optimization with real-time in-process inspection, minimizing human error and ensuring consistency across batches. This technical rigor is particularly vital for California clients operating in regulated sectors like medical devices or aerospace, where dimensional compliance directly impacts safety and certification.

Honyo Prototype delivers tailored CNC solutions engineered for California’s fast-paced innovation landscape. We specialize in rapid turnaround without sacrificing precision, supporting everything from single-part prototypes to small-batch production. Our facility maintains strict adherence to ISO 9001:2015 quality management systems and complies with California-specific environmental standards, including RoHS and REACH directives. Below outlines our core technical capabilities for CNC machining projects:

| Parameter | Specification |

|————————-|———————————————–|

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 17-4PH), Titanium (Gr5), Plastics (PEEK, Delrin, Nylon), Brass, Copper |

| Tolerances | ±0.005 mm (±0.0002″) standard; ±0.002 mm (±0.0001″) for critical features |

| Max Work Envelope | 1000 x 600 x 500 mm (39.4 x 23.6 x 19.7 in) |

| Surface Finish | Ra 0.8 µm (32 µin) standard; Ra 0.4 µm (16 µin) for critical surfaces |

| Lead Time | As fast as 3 business days for simple prototypes; 7–10 days for complex assemblies |

| Quality Assurance | CMM inspection, First Article Inspection (FAI) reports, PPAP documentation |

Our strategic location in Shenzhen provides logistical advantages for global supply chains while maintaining direct coordination with California engineering teams through dedicated project managers. We prioritize transparent communication, sharing real-time process updates and dimensional data to align with your development milestones. Whether you require a single iteration for validation or a bridge-to-production run, Honyo Prototype combines technical excellence with operational agility to accelerate your path from design to deployment. Partner with us to leverage CNC machining that meets California’s high bar for innovation and quality.

Technical Capabilities

CNC California – Advanced Precision Machining Capabilities

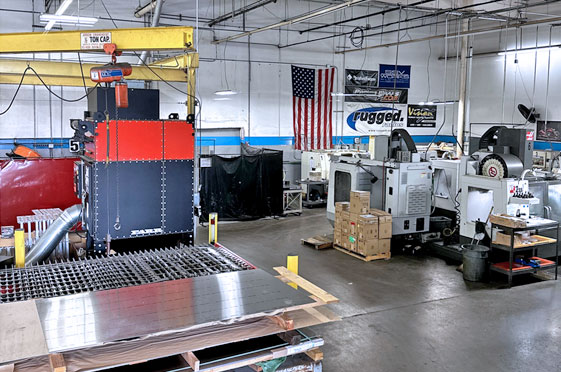

Shenzhen Honyo Prototype delivers high-precision CNC machining services tailored to meet the demanding requirements of industries such as aerospace, medical, automotive, and industrial equipment. Our CNC California division specializes in multi-axis milling, precision turning, and tight-tolerance manufacturing, ensuring consistent quality and repeatability across both prototype and low-volume production runs. Utilizing state-of-the-art equipment and advanced metrology systems, we support complex geometries and stringent dimensional requirements with rapid turnaround times.

Our core capabilities include 3-axis, 4-axis, and 5-axis CNC milling, enabling the efficient machining of intricate parts from a single setup. The transition from 3-axis to full 5-axis simultaneous machining allows us to reduce cycle times, minimize part handling, and achieve superior surface finishes on complex contours. This flexibility supports everything from simple prismatic components to highly engineered organic shapes commonly found in aerospace and medical applications.

In addition to milling, we offer precision CNC turning for cylindrical and rotational components. Our turning centers are equipped with live tooling and Y-axis capabilities, supporting mill-turn operations that combine turning with off-center milling, drilling, and tapping—ideal for complex shafts, fittings, and connectors. These hybrid machines enable complete machining in one setup, reducing lead times and improving part accuracy.

A defining strength of CNC California is our capacity to hold tight tolerances consistently. We routinely maintain tolerances down to ±0.0002″ (±0.005 mm) on critical features, with geometric tolerances controlled via CMM inspection and GD&T-compliant reporting. Our quality management system is ISO 9001:2015 certified, and all processes are supported by first-article inspection, in-process checks, and final validation to ensure compliance with engineering specifications.

The table below outlines our standard tolerance capabilities and compatible materials:

| Operation | Standard Tolerance | Tight Tolerance | Typical Surface Finish (Ra) | Common Materials |

|——————-|——————–|—————–|——————————|——————|

| 3-Axis Milling | ±0.005″ (±0.13 mm) | ±0.0005″ (±0.013 mm) | 32–125 μin (0.8–3.2 μm) | Aluminum 6061, 7075; Steel 1018, 4140; Stainless 303, 316; Titanium Grade 5; Plastics (PEEK, Delrin) |

| 4-Axis Milling | ±0.005″ (±0.13 mm) | ±0.0005″ (±0.013 mm) | 32–125 μin (0.8–3.2 μm) | Same as above |

| 5-Axis Milling | ±0.005″ (±0.13 mm) | ±0.0002″ (±0.005 mm) | 16–63 μin (0.4–1.6 μm) | Same as above |

| CNC Turning | ±0.002″ (±0.05 mm) | ±0.0002″ (±0.005 mm) | 16–63 μin (0.4–1.6 μm) | Same as above |

| Mill-Turn (Live Tooling) | ±0.002″ (±0.05 mm) | ±0.0002″ (±0.005 mm) | 16–63 μin (0.4–1.6 μm) | Same as above |

All materials are sourced to certified mill standards, and material certifications are available upon request. Secondary operations such as deburring, anodizing, passivation, and precision cleaning can be coordinated through our partner network to deliver fully finished components ready for integration.

From CAD to Part: The Process

CNC Machining Production Process: From CAD to Finished Part

Shenzhen Honyo Prototype executes a streamlined, technology-driven workflow to transform customer CAD files into precision CNC-machined components. This process ensures efficiency, quality, and adherence to California industry standards while minimizing lead times. The workflow comprises three integrated phases: AI-Powered Quoting, Comprehensive DFM Analysis, and Rigorous Production Execution.

Our proprietary AI quoting system initiates the process by instantly analyzing uploaded CAD models (STEP, IGES, or native formats). The algorithm assesses geometric complexity, material requirements, and dimensional tolerances to generate an accurate cost and timeline estimate within minutes. This eliminates manual interpretation delays and provides immediate transparency for California-based clients requiring rapid prototyping or low-volume production.

Following quote acceptance, every design undergoes mandatory Design for Manufacturability (DFM) review by our senior engineering team. This critical phase identifies potential production risks before machining begins. Engineers verify minimum wall thicknesses, internal corner radii, hole depth-to-diameter ratios, and tool accessibility. Material-specific constraints—such as aluminum’s susceptibility to chatter or stainless steel’s work-hardening tendencies—are evaluated against requested tolerances. Unresolvable conflicts, like non-machinable undercuts or unrealistic surface finishes, trigger collaborative redesign recommendations to avoid costly revisions mid-production. DFM approval signifies the design is optimized for Honyo’s capabilities and California’s stringent quality expectations.

Production commences only after DFM sign-off. CAD models are converted into machine-specific G-code using Mastercam and Fusion 360, with simulations validating collision-free toolpaths. Parts are machined on our HAAS and DMG MORI 3-axis, 4-axis, and 5-axis CNC centers, all equipped with Renishaw probes for in-process metrology. Material certifications (e.g., AMS, ASTM) are strictly enforced per client specifications, with aluminum 6061-T6, 7075-T6, stainless steel 303/304/316, and titanium Ti-6Al-4V among our most requested California materials. Throughout machining, operators perform iterative inspections against first-article inspection (FAI) reports, ensuring conformance to critical dimensions. Final parts undergo CMM validation, deburring, and optional secondary operations (anodizing, plating, laser engraving) before packaging with full traceability documentation.

Typical Tolerance Capabilities by Material

| Material Category | Standard Tolerance (mm) | Tight Tolerance (mm) | Critical Feature Notes |

|——————-|————————-|———————-|————————————–|

| Aluminum Alloys | ±0.05 | ±0.005 | Achievable on non-critical faces; ±0.01 typical for bores |

| Stainless Steel | ±0.03 | ±0.008 | Requires rigid setups; ±0.015 for deep pockets |

| Titanium | ±0.05 | ±0.01 | Slow feed rates; stringent chip control essential |

| Engineering Plastics | ±0.1 | ±0.025 | Thermal expansion requires compensated toolpaths |

This workflow—AI Quote → DFM → Production—ensures California clients receive dimensionally accurate, functionally validated parts on schedule. By embedding engineering rigor at every stage, Honyo Prototype mitigates risk, reduces total project cost, and delivers components ready for immediate integration into end-use applications.

Start Your Project

Start Your CNC Machining Project with Shenzhen Honyo Prototype – Precision You Can Trust

When it comes to high-precision CNC machining for prototyping and low-volume production, Shenzhen Honyo Prototype delivers unmatched quality, speed, and technical expertise. Whether you’re an engineer, product designer, or procurement manager based in California or across North America, launching your next project with us is seamless, efficient, and cost-effective. Our advanced CNC capabilities support a wide range of materials, tight tolerances, and complex geometries—ensuring your components meet exact specifications every time.

At Honyo Prototype, we specialize in turning your CAD designs into fully functional parts with rapid turnaround times. Our state-of-the-art 3-axis, 4-axis, and 5-axis CNC machining centers are operated by experienced engineers who understand the demands of precision manufacturing. From aluminum and stainless steel to engineering plastics like PEEK and Delrin, we offer material versatility without compromising accuracy. With in-house quality control and ISO 9001-certified processes, every part undergoes rigorous inspection to ensure compliance with your technical requirements.

We recognize that starting a new manufacturing project involves more than just submitting a drawing—it requires collaboration, clear communication, and trust in your manufacturing partner. That’s why we assign a dedicated project manager to every client. For customers in California and across the U.S., Susan Leo serves as your direct point of contact, guiding you from initial inquiry to final delivery. With deep expertise in CNC prototyping and customer logistics, Susan ensures your project stays on schedule, within budget, and aligned with your engineering goals.

To get started, simply send your 2D/3D drawings in any standard format (STEP, IGES, DWG, PDF, etc.) to Susan Leo at info@hy-proto.com. Within hours, you’ll receive a detailed technical feedback report and a competitive quote. Our team proactively reviews designs for manufacturability, suggesting optimizations to reduce cost and lead time without sacrificing performance.

Below are key technical specifications for our CNC machining services:

| Parameter | Capability |

|—————————|———————————————–|

| Machine Types | 3-axis, 4-axis, 5-axis CNC milling and turning |

| Positioning Accuracy | ±0.005 mm |

| Standard Tolerances | ±0.05 mm (tight tolerances down to ±0.005 mm) |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Brass, Titanium, PEEK, ABS, PC, Nylon, and more |

| Max Work Envelope | 1200 x 600 x 500 mm (47 x 23.6 x 19.7 in) |

| Surface Finishes | As-machined, Anodizing (Type II & III), Powder Coating, Plating, Bead Blasting, Polishing |

| Lead Time | As fast as 3–5 days for prototypes |

| Quality Standards | ISO 9001:2015 compliant, Full inspection reports available (CMM, FAI) |

Partnering with Honyo Prototype means gaining access to a streamlined, transparent, and responsive manufacturing process designed for innovation-driven industries. Whether you need a single prototype or a small production run, we are equipped to support your success.

Contact Susan Leo today at info@hy-proto.com to start your CNC machining project with confidence. Let Honyo Prototype be your trusted manufacturing partner in bringing precision-engineered ideas to life.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.