Contents

Manufacturing Insight: Corrosion Resistant Steel Grades

Strategic Material Selection for Corrosion Resistant Steel in Precision CNC Machining

Corrosion resistant steel grades are critical for components operating in demanding environments across aerospace, medical, marine, and chemical processing industries. These alloys derive their protective properties primarily from chromium content (typically >10.5%), which forms a passive oxide layer, often enhanced by elements like nickel, molybdenum, and nitrogen. While “stainless” implies resistance, performance varies significantly based on the specific grade, environmental conditions (e.g., chloride exposure, pH, temperature), and crucially, the integrity of the final machined surface. Poor machining practices can compromise the passive layer through heat generation, micro-cracking, or embedded contaminants, leading to premature localized corrosion such as pitting or crevice attack. Understanding these material nuances is not merely an option but a fundamental requirement for ensuring component longevity and system reliability.

At Shenzhen Honyo Prototype, we recognize that successful implementation of corrosion resistant steels extends far beyond simple material specification. Our CNC machining expertise is deeply integrated with metallurgical knowledge, allowing us to optimize every stage of production for these sensitive alloys. We prioritize strategic grade selection aligned with the specific service environment, moving beyond generic recommendations to mitigate risk effectively. Our process begins with rigorous material certification verification and continues through precision machining parameters meticulously developed to minimize heat input and work hardening – common pitfalls that degrade corrosion performance. We employ specialized tool geometries, controlled coolant strategies, and precise feed/speed regimes tailored to each alloy’s characteristics. Critically, we implement stringent post-machining protocols including proprietary passivation sequences and electropolishing capabilities, which actively restore and enhance the protective oxide layer, ensuring the surface finish directly contributes to, rather than detracts from, the component’s corrosion resistance. Our dedicated quality control lab utilizes salt spray testing (ASTM B117) and ferroxyl testing to validate surface integrity against project-specific requirements.

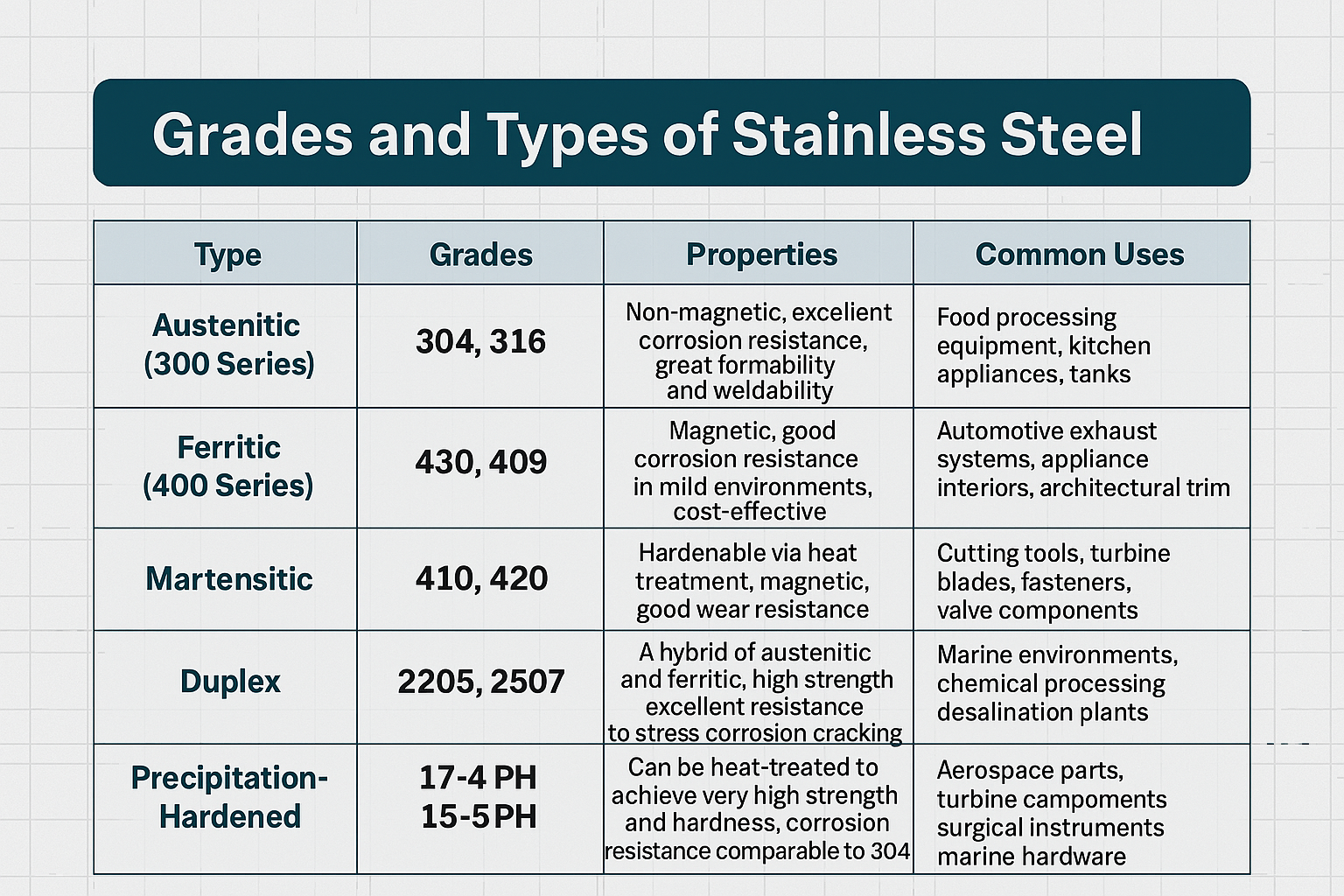

The table below outlines key corrosion resistant steel grades frequently processed at Honyo, highlighting properties critical to CNC manufacturability and end-use performance:

| Steel Grade | Key Corrosion Resistance | Machinability (Rating) | Typical CNC Applications |

|————-|————————–|————————|————————–|

| 316L (1.4404) | Excellent resistance to chlorides & acids; Molybdenum (2-3%) enhances pitting resistance | Moderate (B1112 equivalent) | Marine hardware, chemical valves, medical implants |

| 17-4 PH (1.4542) | Good general corrosion resistance; Precipitation hardening for high strength | Moderate to Good (after solution treat) | Aerospace actuators, pump shafts, nuclear components |

| 904L (1.4539) | Superior resistance to sulfuric acid & seawater; High Ni/Mo/Cu content | Fair (gummy, requires sharp tools) | Flue gas desulfurization, acid handling equipment |

| 2205 Duplex (1.4462) | Excellent chloride stress corrosion cracking resistance; Balanced austenitic-ferritic | Moderate (work hardens rapidly) | Offshore oil & gas, desalination plants, pressure vessels |

Honyo Prototype’s value lies in translating material science into robust, production-ready components. We partner with clients during the design phase to address manufacturability concerns inherent to corrosion resistant steels, such as managing distortion during heat treatment or achieving critical surface finishes. Our commitment ensures that the exceptional properties of these advanced alloys are fully realized in the final part, delivering performance integrity you can rely on in the most challenging operational contexts. Trust Honyo to bridge the gap between material specification and functional, long-lasting corrosion resistance.

Technical Capabilities

Corrosion Resistant Steel Grades – Technical Capabilities in CNC Machining

Shenzhen Honyo Prototype specializes in high-precision CNC machining of corrosion resistant steel grades, leveraging advanced 3-axis, 4-axis, and 5-axis milling platforms, as well as multi-task turning centers. Our manufacturing expertise ensures reliable production of complex, mission-critical components used in aerospace, medical, marine, and chemical processing industries—environments where material integrity and dimensional accuracy under harsh conditions are paramount.

Our facility is optimized for machining high-performance stainless steels and nickel-based alloys renowned for their resistance to oxidation, pitting, and stress corrosion cracking. Primary materials include AISI 316L, 17-4 PH, 15-5 PH, 440C, and Alloy 625, all processed under tightly controlled parameters to maintain passive oxide layer integrity and microstructural consistency. These grades are selected for their excellent strength-to-weight ratios, weldability, and long-term stability in aggressive environments.

Honyo Prototype’s CNC machining centers are equipped with high-speed spindles, thermal compensation systems, and in-process probing, enabling us to maintain tight tolerances across complex geometries. Our 5-axis simultaneous machining capability allows for single-setup fabrication of intricate contours and undercuts, minimizing part handling and improving geometric accuracy. For rotational components, precision turning operations are performed on CNC lathes with live tooling, supporting full mill-turn workflows for highly integrated parts.

Dimensional accuracy is a cornerstone of our service offering. We consistently achieve tolerances down to ±0.005 mm on critical features, with surface finishes as fine as Ra 0.4 µm achievable through dedicated finishing toolpaths and post-processing options. All processes are supported by comprehensive first-article inspection and ongoing in-process metrology using coordinate measuring machines (CMM) and optical comparators, ensuring full compliance with ISO 2768 and customer-specific standards.

The following table outlines the typical tolerance capabilities and compatible materials for each machining process:

| Process | Typical Tolerance (± mm) | Surface Finish (Ra µm) | Max Part Size (mm) | Compatible Corrosion Resistant Grades |

|—————–|—————————|————————-|——————–|————————————————————|

| 3-Axis Milling | 0.010 | 1.6 – 3.2 | 600 x 400 x 300 | 316L, 304L, 17-4 PH, 440C |

| 4-Axis Milling | 0.008 | 1.6 – 2.4 | 500 x 400 x 250 | 316L, 15-5 PH, 17-4 PH, Alloy 625 |

| 5-Axis Milling | 0.005 | 0.8 – 1.6 | 400 x 400 x 200 | 316L, 17-4 PH, 15-5 PH, 440C, Alloy 625, Inconel 718 |

| CNC Turning | 0.005 | 0.4 – 1.6 | Ø400 x 600 length | 316L, 303, 17-4 PH, 416, 440C, 15-5 PH |

| Mill-Turn | 0.005 | 0.8 – 1.6 | Ø200 x 400 length | 316L, 17-4 PH, 15-5 PH, Alloy 625 |

All corrosion resistant steel components undergo post-machining passivation per ASTM A967 (HNO3 or Citric methods) or AMS 2700 to enhance surface oxide formation and remove free iron contamination. Optional electropolishing is available for improved microfinish and biocompatibility, particularly for medical applications.

At Shenzhen Honyo Prototype, we combine advanced CNC capabilities with deep metallurgical understanding to deliver precision-machined corrosion resistant components that meet the highest performance and reliability standards.

From CAD to Part: The Process

Production Process: CAD to Part for Corrosion-Resistant Steel Grades

The successful CNC machining of corrosion-resistant steel components at Shenzhen Honyo Prototype follows a rigorously defined workflow, critically adapted for the unique metallurgical properties of these demanding materials. This workflow ensures optimal part integrity, dimensional accuracy, and corrosion performance while maximizing efficiency. The sequence begins with the AI-Powered Quotation Phase. Upon receiving the customer’s CAD model, our proprietary AI system instantly analyzes geometric complexity, material specifications (explicitly identifying grades like 316L, 17-4PH, or duplex 2205), and required tolerances. Crucially, the AI cross-references this data against our extensive database of material-specific machining parameters, tool wear rates, and historical production costs for corrosion-resistant alloys. This generates an accurate, data-driven quote that factors in the higher tooling costs, slower achievable feed rates, and potential need for specialized coolants inherent to these steels, providing immediate transparency on cost drivers related to material selection.

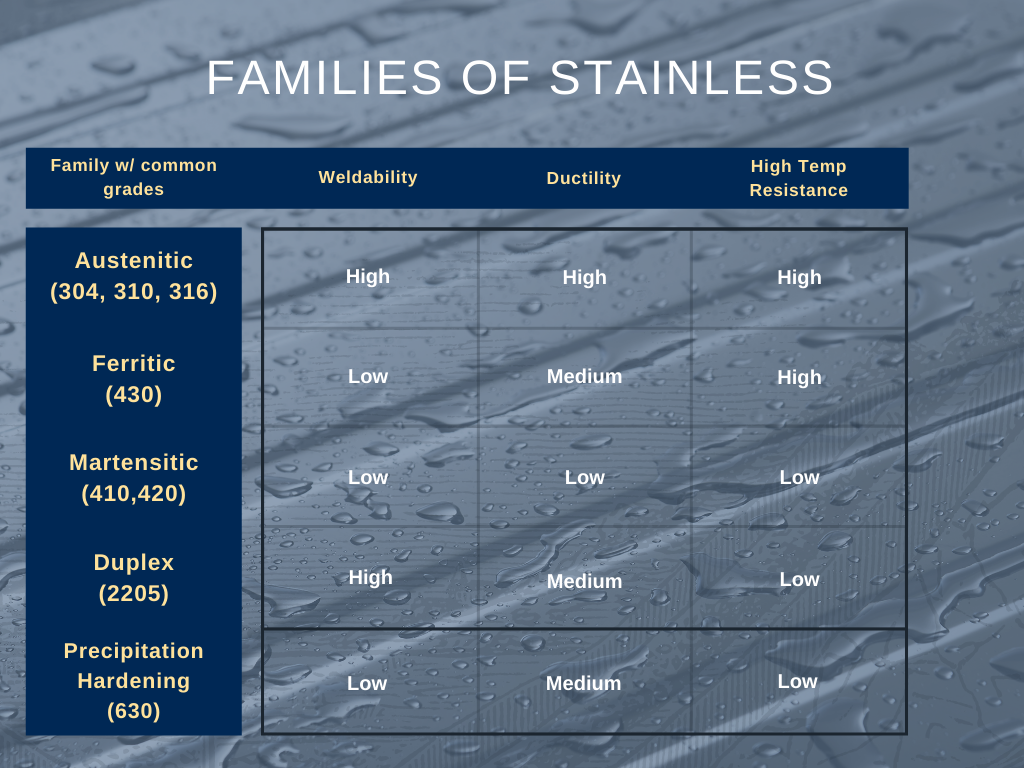

The subsequent Design for Manufacturability (DFM) Review is where deep material expertise becomes paramount. Our manufacturing engineers conduct a thorough analysis, focusing specifically on challenges posed by corrosion-resistant steels. We scrutinize features prone to work hardening (common in austenitic grades like 304/316), assess the risk of built-up edge, and evaluate thermal management requirements to prevent microstructural damage. Recommendations often include optimizing wall thicknesses to minimize vibration during machining, suggesting controlled depth-of-cut strategies to mitigate strain hardening, specifying appropriate tool geometries (e.g., positive rake angles for 316L), and defining stringent surface finish requirements critical for passive layer formation. This phase ensures the design is not only manufacturable but also optimized for the specific corrosion resistance mechanism of the chosen grade, preventing costly redesigns or performance failures downstream.

Production Execution leverages the insights from the AI quote and DFM phase. Machining commences on our high-precision CNC centers equipped with robust spindles and advanced coolant delivery systems capable of handling the thermal loads of these tough alloys. Programs utilize material-specific cutting parameters derived from our DFM analysis – typically lower surface speeds and controlled feed rates compared to mild steel, especially for grades like 17-4PH or super duplex. Strict process monitoring tracks tool wear in real-time; carbide or ceramic tooling is employed, with frequent inspections mandated due to accelerated wear rates. Critical to corrosion performance, meticulous attention is paid to surface integrity: avoiding micro-cracks, minimizing residual stresses through optimized toolpaths and potential stress-relief steps, and ensuring final surfaces meet Ra specifications to facilitate effective passivation. Rigorous in-process inspection verifies dimensions and critical features before final passivation and testing.

Key corrosion-resistant steel grades and their machining characteristics are summarized below:

| Grade | Primary Composition | Corrosion Resistance Focus | Key Machining Considerations for CNC |

| :———— | :———————– | :———————————- | :——————————————————- |

| AISI 316L | 16-18% Cr, 10-14% Ni, 2-3% Mo | Chlorides, acids, marine environments | High work hardening; requires sharp tools, consistent cuts, adequate coolant; prone to galling |

| 17-4PH | 15-17.5% Cr, 3-5% Cu, ~4% Ni | Moderate chlorides, general service | Precipitation hardening; machine in annealed state; can be abrasive; requires rigid setup |

| Duplex 2205 | 22% Cr, 5-6% Ni, 3% Mo | High chloride, acidic environments | Moderate work hardening; thermal sensitivity; requires precise coolant control; abrasive |

| AISI 440C | 16-18% Cr, High C | Mild environments, high wear | Extremely hard (after heat treat); very abrasive; requires diamond/CBN tooling; low MRR |

This integrated AI Quote -> DFM -> Production workflow, deeply informed by the metallurgical demands of corrosion-resistant steels, ensures Honyo Prototype delivers components where dimensional precision and long-term environmental resistance are non-negotiable requirements. Continuous process validation and material traceability underpin final part certification.

Start Your Project

Start Your Project with High-Performance Corrosion Resistant Steel Grades

When precision, durability, and environmental resistance are critical to your next CNC machining project, selecting the right material is paramount. At Shenzhen Honyo Prototype, we specialize in manufacturing high-integrity components using advanced corrosion resistant steel grades tailored to meet the demands of aerospace, medical, marine, and industrial applications. Our expertise ensures your prototypes and production parts perform reliably in even the most aggressive environments.

Corrosion resistant steel grades offer superior protection against oxidation, chemical exposure, and moisture—key factors in extending service life and reducing maintenance costs. Whether your application involves saline environments, acidic conditions, or high-temperature operations, our engineered solutions deliver consistent performance and structural integrity.

We work with a range of premium alloys designed to resist pitting, crevice corrosion, and stress cracking. Our CNC machining capabilities support tight tolerances, complex geometries, and scalable production runs—all backed by rigorous quality control and material traceability.

To help you make an informed decision, below is a comparative overview of commonly used corrosion resistant steel grades we machine:

| Steel Grade | Common Name | Key Properties | Typical Applications |

|———–|————-|—————-|———————–|

| 316L Stainless Steel | Marine Grade Stainless | Excellent chloride resistance, low carbon content reduces sensitization during welding | Marine hardware, chemical processing, medical implants |

| 17-4 PH Stainless Steel | Precipitation Hardening Steel | High strength, good corrosion resistance, heat-treatable | Aerospace components, valves, pump shafts |

| 904L Stainless Steel | Super Austenitic Stainless | Exceptional resistance to sulfuric acid and seawater | Petrochemical, offshore platforms, flue gas desulfurization |

| 2205 Duplex Stainless Steel | Duplex 2205 | High strength, excellent resistance to stress corrosion cracking | Oil & gas pipelines, pressure vessels, heat exchangers |

| Inconel 625 | Nickel-Based Alloy | Outstanding oxidation and corrosion resistance at elevated temperatures | Jet engines, submarine components, chemical tanks |

Each material is selected based on environmental exposure, mechanical requirements, and regulatory standards. Our engineering team provides full consultation to ensure optimal material selection for your specific use case.

Starting your project with Shenzhen Honyo Prototype means partnering with a manufacturer that combines technical expertise with advanced CNC machining technology. From initial design review to final inspection, we ensure every component meets your exact specifications.

Don’t leave material performance to chance. Let our team guide you through the selection and machining process to achieve optimal results.

Contact Susan Leo today for personalized support and a fast quotation.

Email: info@hy-proto.com

We respond within 4 business hours to all project inquiries.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.