Contents

Manufacturing Insight: Cnc Machined Products

Manufacturing Insight: Precision CNC Machined Products at Honyo Prototype

Computer Numerical Control (CNC) machining remains the cornerstone of modern precision manufacturing, particularly for rapid prototyping and low-to-medium volume production of complex, high-integrity components. At Shenzhen Honyo Prototype, we leverage this subtractive manufacturing technology to transform digital CAD models into physical parts with exceptional accuracy, repeatability, and material versatility. CNC machining utilizes computer-controlled machine tools—mills, lathes, and multi-axis centers—to systematically remove material from a solid workpiece (billet or casting). This process excels where tight tolerances, superior surface finishes, structural integrity, and the use of engineering-grade metals and plastics are critical requirements, making it indispensable for functional prototypes, validation testing, and end-use parts across aerospace, medical, automotive, and industrial sectors.

Honyo Prototype operates a dedicated CNC facility equipped with advanced machinery and staffed by experienced manufacturing engineers and machinists. Our core strength lies in rapidly producing high-fidelity prototypes and bridge production parts that accurately reflect final production intent, enabling our clients to de-risk product development cycles significantly. We specialize in handling complex geometries that challenge conventional manufacturing, utilizing both 3-axis and sophisticated 5-axis simultaneous machining capabilities to minimize setups and achieve intricate features in a single operation. Material selection is a key differentiator; our processes support an extensive range of metals including aluminum alloys (6061, 7075), stainless steels (303, 304, 316), titanium, brass, and copper, alongside high-performance engineering plastics such as PEEK, Delrin, Nylon, and PTFE.

Our commitment to precision is quantifiable, consistently achieving tight tolerances essential for critical assemblies. The table below outlines the core capabilities of our primary CNC equipment:

| Machine Type | Travel Range (X-Y-Z) | Typical Tolerance | Material Compatibility |

| :—————– | :——————- | :—————- | :———————————- |

| 3-Axis Vertical Mills | 1000 x 500 x 500 mm | ±0.010 mm | Metals, Plastics, Composites |

| 4/5-Axis Mills | 800 x 500 x 400 mm | ±0.005 mm | Metals, High-Performance Plastics |

| CNC Lathes (Swiss) | Ø32 mm max bar stock | ±0.005 mm | Metals, Plastics (rod stock) |

Beyond raw machining capability, Honyo integrates comprehensive quality control throughout the process. Every critical dimension is verified using calibrated CMMs, optical comparators, and surface roughness testers, with full inspection reports provided. Our engineering team actively collaborates with clients during the Design for Manufacturability (DFM) stage, offering actionable feedback to optimize part geometry for cost-effective CNC production without compromising function. This proactive approach, combined with streamlined workflows and rapid quotation systems, ensures accelerated time-to-part—often within days—without sacrificing the dimensional accuracy or material properties demanded by rigorous application environments. Partnering with Honyo Prototype provides access to CNC machining expertise that translates complex designs into reliable, high-performance physical assets, accelerating innovation from concept to validation.

Technical Capabilities

Shenzhen Honyo Prototype delivers precision CNC machined components tailored for industries requiring high accuracy, repeatability, and rapid turnaround. Our advanced CNC machining capabilities include 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, enabling us to produce complex geometries and tight-tolerance parts across a broad range of engineering materials. With state-of-the-art equipment and a team of experienced manufacturing engineers, we support prototyping and low-to-mid volume production with consistent quality and fast lead times.

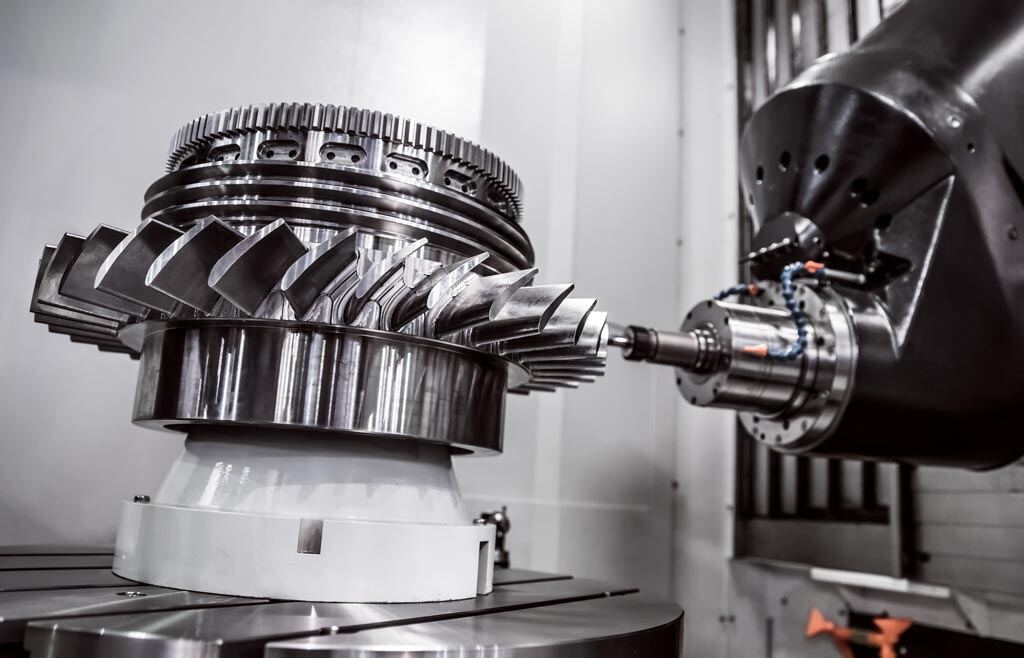

Our 3-axis milling services are ideal for prismatic parts and standard geometries with straightforward tool access. For components requiring multi-sided machining or angled features, our 4-axis and 5-axis CNC machining centers provide enhanced flexibility and precision. These multi-axis systems reduce the need for multiple setups, improving accuracy and reducing production time. Simultaneous 5-axis machining allows for the creation of complex organic shapes, turbine blades, impellers, and aerospace components with superior surface finishes.

CNC turning is employed for cylindrical or rotationally symmetric parts such as shafts, bushings, and fittings. Our turning centers support both standard and Swiss-type turning, accommodating long, slender parts with high aspect ratios. We integrate live tooling to perform milling, drilling, and tapping during the turning process, enabling complete machining in a single setup.

A core strength at Honyo Prototype is our ability to hold tight tolerances consistently. We routinely achieve dimensional tolerances down to ±0.005 mm (±0.0002″) on critical features, with geometric tolerances controlled per ISO 2768 and ASME Y14.5 standards. Surface finishes as fine as Ra 0.4 µm (16 µin) are attainable through precision tooling and optimized cutting strategies. All parts undergo rigorous in-process and final inspection using calibrated CMMs, optical comparators, and surface roughness testers to ensure compliance with customer specifications.

The table below outlines our standard technical capabilities and material compatibility for CNC machined products:

| Capability | Specification |

|———-|—————|

| Milling | 3-axis, 4-axis, 5-axis (simultaneous) |

| Turning | CNC turning, Swiss-type turning with live tooling |

| Max Work Envelope (Milling) | 1000 × 600 × 500 mm |

| Max Work Envelope (Turning) | Ø300 mm diameter × 500 mm length |

| Standard Tolerance | ±0.025 mm (±0.001″) |

| Tight Tolerance | ±0.005 mm (±0.0002″) achievable |

| Surface Finish (Typical) | Ra 3.2 – 1.6 µm (125 – 63 µin) |

| Fine Surface Finish | Ra 0.8 – 0.4 µm (32 – 16 µin) |

| Material Category | Examples |

|——————|———|

| Metals | Aluminum 6061, 7075; Stainless Steel 303, 304, 316; Steel 1018, 4140; Titanium Grade 2, 5; Brass C360; Copper |

| Plastics | ABS, POM (Delrin), Nylon, PC, PEEK, PMMA, UHMW |

| Others | Magnesium, Inconel 718, Tool Steels (e.g., S136, NAK80 for mold applications) |

We support customer drawings in all standard formats and apply DFMA principles to optimize manufacturability, reduce cost, and accelerate delivery. Whether for functional prototypes, end-use parts, or bridge production, Honyo Prototype ensures every CNC machined component meets the highest standards of precision and quality.

From CAD to Part: The Process

CNC Machined Products: Production Process Workflow

At Shenzhen Honyo Prototype, our CNC machining process transforms your digital design into a high-precision physical part through a rigorously defined workflow. This structured approach ensures manufacturability, quality, and efficiency from initial concept to final delivery. The core sequence involves AI-Powered Quoting, Comprehensive Design for Manufacturability (DFM) Analysis, and Precision Production Execution.

The workflow initiates upon receipt of your CAD model. Our proprietary AI quoting system performs an immediate, detailed analysis of the geometry, material selection, required tolerances, and surface finishes. This system rapidly evaluates machine time, tooling complexity, material utilization, and potential secondary operations to generate an accurate, data-driven cost estimate and lead time projection within minutes. This initial AI assessment provides crucial transparency early in the procurement cycle, allowing for informed project decisions before formal commitment.

Following quote acceptance, the design enters our critical DFM phase. Honyo’s experienced manufacturing engineers meticulously review the CAD model, focusing explicitly on optimizing it for CNC production. This involves identifying and resolving potential issues such as non-manufacturable features, inadequate tool access, problematic wall thicknesses, excessive tolerance requirements leading to unnecessary cost, or suboptimal material choices. We assess feature geometry for efficient toolpath generation, evaluate fixturing requirements, and consider tolerancing strategy to prevent stack-up issues. Crucially, our engineers intervene proactively, providing clear, actionable feedback and collaborative suggestions for design modifications that enhance manufacturability without compromising functional intent. This step is paramount for avoiding costly delays, rework, and scrap during machining.

Upon DFM validation and final design sign-off, the part progresses to production. Certified CAM programmers generate optimized, collision-free toolpaths based on the approved design and material. These programs are rigorously verified using simulation software before deployment to the shop floor. Honyo utilizes a modern fleet of precision 3-axis, 4-axis, and 5-axis CNC machining centers, equipped with high-quality tooling and probing systems. Machining occurs under strict process controls, with in-process inspections verifying critical dimensions at defined stages. Post-machining, parts undergo final dimensional inspection against the original drawing using calibrated CMMs or optical comparators, followed by required surface finishing operations. Comprehensive documentation accompanies every shipment.

Key production parameters consistently achieved across our facility include:

| Parameter | Standard Capability | Tight Tolerance Option |

| :—————– | :———————— | :——————— |

| Dimensional Tolerance | ±0.05 mm (±0.002″) | ±0.0125 mm (±0.0005″) |

| Surface Roughness | Ra 3.2 µm (125 µin) | Ra 0.8 µm (32 µin) |

| Common Materials | Aluminum 6061/7075, Steel 1018/4140, Stainless 303/304, Plastics (ABS, PC, POM) | Titanium, Inconel |

| Max Work Envelope | 1000 x 600 x 500 mm | Custom solutions available |

This integrated workflow—AI Quote enabling speed, DFM ensuring robustness, and Precision Production guaranteeing quality—forms the backbone of Honyo Prototype’s CNC machining service, delivering reliable, high-integrity components for demanding applications.

Start Your Project

Start Your CNC Machining Project with Shenzhen Honyo Prototype

When it comes to precision manufacturing, CNC machined products are the backbone of innovation across industries such as aerospace, medical devices, automotive, and consumer electronics. At Shenzhen Honyo Prototype, we specialize in delivering high-accuracy, repeatable, and scalable CNC machining solutions tailored to your project requirements. Whether you’re developing a single prototype or preparing for low-to-mid volume production, our advanced capabilities and engineering expertise ensure your design is translated into a high-performance component with minimal lead time.

Our state-of-the-art CNC machining center is equipped with 3-axis, 4-axis, and 5-axis milling machines, as well as precision turning centers, enabling us to handle complex geometries and tight tolerances down to ±0.005 mm. We support a wide range of engineering-grade materials, including aluminum alloys (6061, 7075), stainless steel (303, 304, 316), titanium, brass, copper, and engineering plastics such as PEEK, Delrin, and nylon. Surface finishes, post-processing treatments, and custom finishing options—including anodizing, bead blasting, powder coating, and passivation—are available to meet your functional and aesthetic standards.

We understand that every project begins with a concept. That’s why our engineering team works closely with clients from the initial design phase to ensure manufacturability, cost efficiency, and performance optimization. Our Design for Manufacturing (DFM) feedback is provided early in the process, helping you avoid costly redesigns and production delays.

To get started, simply upload your 3D CAD model (STEP, IGES, or X_T format) or 2D technical drawings with dimensions and tolerances. Our quoting system processes your file within 12 hours, and our manufacturing lead times typically range from 3 to 10 business days, depending on complexity and volume.

Below are our standard CNC machining specifications for quick reference:

| Parameter | Specification |

|————————-|———————————————–|

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Maximum Work Envelope | 1000 × 600 × 500 mm (40″ × 24″ × 20″) |

| Axis Capabilities | 3-axis, 4-axis, 5-axis milling; CNC turning |

| Common Materials | Aluminum, steel, stainless steel, titanium, brass, PEEK, Delrin, nylon |

| Standard Tolerance | ±0.05 mm (tighter upon request) |

| Lead Time (Prototype) | 3–7 working days |

| Lead Time (Production) | 5–10 working days |

| Finishes & Treatments | As-machined, anodizing, bead blasting, powder coating, passivation, plating |

Starting your project with Honyo Prototype is simple and efficient. For personalized support and a fast quotation, contact Susan Leo directly at info@hy-proto.com. Include your design files and project specifications, and our team will respond promptly with a detailed quote and DFM analysis. We are committed to accelerating your product development cycle with precision, reliability, and responsive service. Let us be your trusted partner in turning concepts into high-quality CNC machined components.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.