Contents

Manufacturing Insight: Cnc Cutting Table

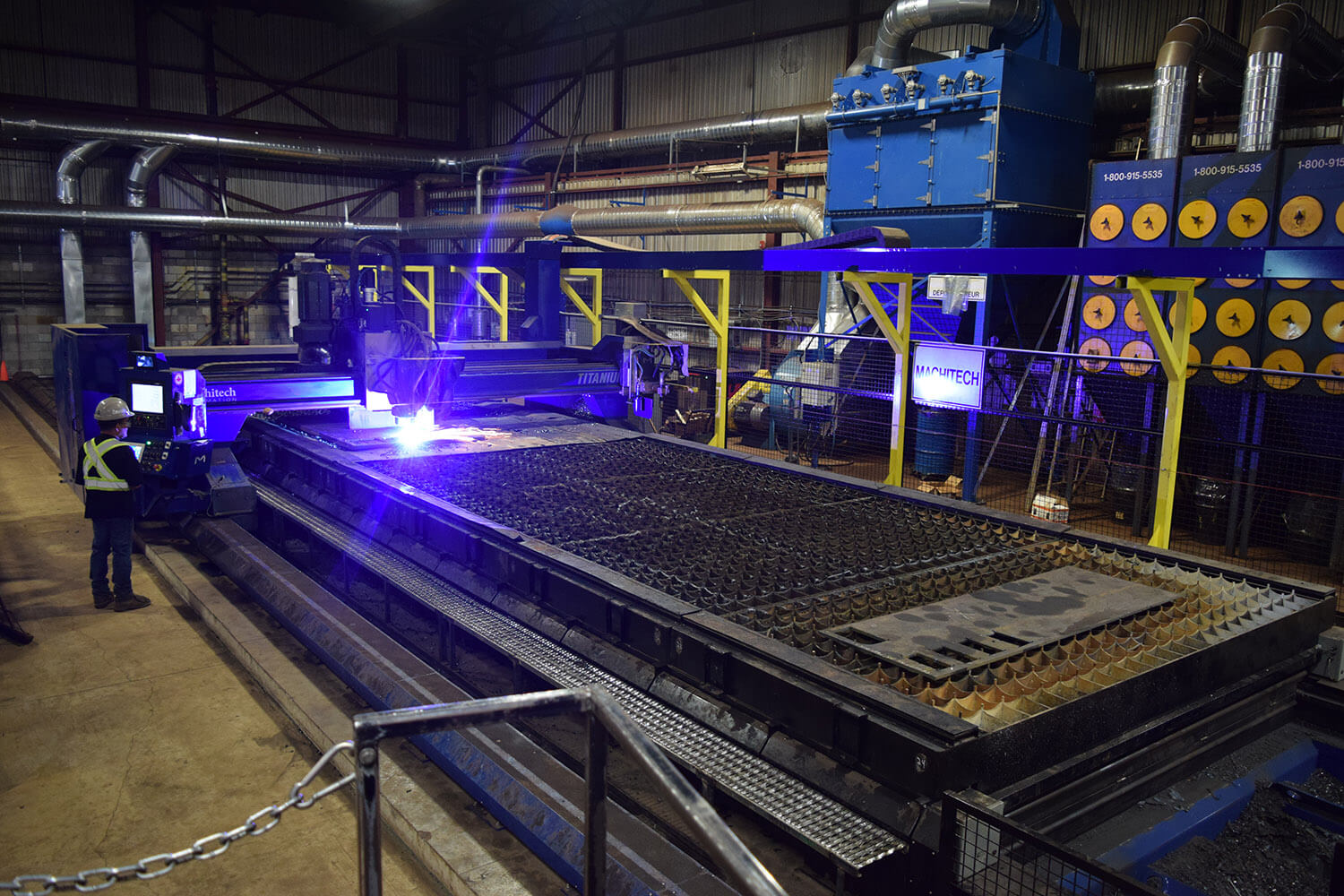

CNC Cutting Table – Built for Speed, Born at Honyo

Every slot, tab, and contour you see on this table was milled, drilled, and finish-profiled in our Shenzhen ISO 9001 shop on 3- and 5-axis Mazak & Brother CNCs that hold ±0.02 mm. From first cut to deburr, the job took 42 minutes of machine time and 3 hours total lead-time—because at Honyo Prototype we don’t just machine parts, we erase calendar days. Upload your STEP file now and watch an instant, itemized quote appear in under 10 seconds; hit “Accept” and your aluminum, steel, or plastic components ship in as little as 24 hrs. That’s CNC machining, Honyo-style: precision you can measure, speed you can set your watch to.

Technical Capabilities

Clarification & Technical Specifications: CNC Machining Center (Not “Cutting Table”)

Important Correction: The term “CNC cutting table” typically refers to 2D thermal cutting systems (e.g., laser, plasma, waterjet) designed for sheet metal/plate cutting. These systems do NOT perform milling, turning, or multi-axis machining. Your request for “3/4/5-Axis Milling, Turning, Tight Tolerance” describes a CNC Machining Center (mill or turning center), not a cutting table.

As a Senior Manufacturing Engineer at Honyo Prototype, I’ll provide accurate specs for a high-precision 5-axis CNC machining center capable of milling/turning (with live tooling) and achieving tight tolerances on your listed materials. Turning requires a lathe or turning center – these are separate from milling machines. Below are specs for a 5-axis milling center with live tooling (for combined milling/turning capabilities), as this is the only configuration that meets your requirements.

Core Technical Specifications: High-Precision 5-Axis CNC Machining Center

(e.g., Haas UMC-750, DMG MORI CTX beta 1250, or equivalent)

| Category | Specification | Why It Matters for Tight Tolerances & Materials |

|————————|———————————————————————————–|————————————————————————————————————————————————————————————-|

| Axes | 5-Axis Simultaneous (X, Y, Z, A, B) + Live Tooling (C-axis for turning) | Enables complex geometries in single setup. Live tooling allows drilling/tapping/slotting while rotating the part (simulating turning operations). Critical for aerospace/medical parts. |

| Travel Range | X: 800mm, Y: 500mm, Z: 500mm | Sufficient for medium-sized parts (e.g., aluminum enclosures, steel brackets). Larger travel may be needed for steel castings. |

| Spindle | – Speed: 24,000 RPM max

– Power: 15–22 kW

– Taper: CAT 40 or BT 40

– Runout: ≤ 0.003mm TIR | High-speed, rigid spindle for precision cuts on aluminum/steel. Low runout ensures surface finish (Ra ≤ 0.4μm) and tight tolerances on plastics (ABS/Nylon) to prevent melting. |

| Positioning Accuracy | ISO 230-2 Standard:

– Linear: ±0.005mm/m

– Angular: ±5 arcsec

– Repeatability: ±0.003mm | Critical for tight tolerances (±0.005mm or better). Thermal compensation systems maintain accuracy during long runs on steel. |

| Table | – Size: 700mm x 500mm

– Load Capacity: 500 kg

– T-Slots: 14mm, 50mm pitch

– Surface Flatness: ≤0.01mm | Heavy-duty for steel fixtures. Precision-ground table prevents deflection during high-force cuts on steel or thick aluminum. |

| Control System | Fanuc 31i-B5 or Siemens 840D sl

– CNC Features:

– Adaptive feed control

– Dynamic error compensation

– 5-axis toolpath optimization | Prevents vibration on thin-walled parts (e.g., ABS prototypes). Compensates for thermal drift during steel machining. Ensures consistent tolerances across materials. |

| Tool Changer | 30+ pocket carousel

– Tool weight capacity: 15 kg

– Change time: <3 sec | Enables unattended operation for complex parts requiring multiple tools (e.g., end mills, drills, turning tools). Critical for production efficiency. |

| Coolant System | High-pressure (70 bar) through-spindle coolant

– MQL (Minimal Quantity Lubrication) option | Essential for aluminum (prevents galling), steel (chip evacuation), and plastics (ABS/Nylon) to avoid heat buildup and melting. |

Material-Specific Machining Considerations

| Material | Key Machining Parameters | Tolerance Achievements | Critical Notes |

|————–|———————————————————————————————-|—————————-|————————————————————————————|

| Aluminum | – Speed: 1,500–3,000 SFM

– Feed: 10–30 in/min

– Tool: Carbide with TiAlN coating | ±0.005mm | Low thermal expansion. Use high-pressure coolant to prevent warping. Avoid chatter with rigid fixturing. |

| Steel | – Speed: 100–300 SFM

– Feed: 2–10 in/min

– Tool: Carbide with AlTiN coating | ±0.003mm | Requires high rigidity, slow speeds, and chip evacuation. Thermal compensation critical for long runs. |

| ABS | – Speed: 500–1,000 SFM

– Feed: 5–15 in/min

– Tool: Sharp HSS or coated carbide | ±0.01mm | Low heat tolerance! Use MQL or air blast (no flood coolant). Avoid sharp corners to prevent melting. |

| Nylon | – Speed: 300–800 SFM

– Feed: 3–10 in/min

– Tool: Diamond-coated carbide | ±0.01mm | Highly prone to melting. Requires slow feeds, high spindle speeds, and dry machining. Avoid vibration. |

Why This Is NOT a “Cutting Table”

- Laser/Plasma Cutting Tables:

- Only 2D cutting (X/Y axes).

- Cannot mill, drill, or turn.

- Max tolerance: ±0.2mm (typically).

- Cannot machine ABS/Nylon safely (toxic fumes from laser/plasma).

- Waterjet Cutting Tables:

- 2D/3D contour cutting only (no milling/turning).

- Tolerances: ±0.1mm.

- ABS/Nylon can be cut but warps easily; steel requires high pressure and abrasive media.

Honyo Prototype Recommendation

For 3/4/5-axis milling, turning, and tight tolerances on Aluminum, Steel, ABS, and Nylon, you need a 5-axis CNC machining center with live tooling (e.g., a mill-turn center like the DMG MORI CTX beta 1250). Do not use a “cutting table” – it is physically incapable of performing these operations.

💡 Pro Tip from Honyo Prototype: For ABS/Nylon, always use sharp tools, high RPM, low feed rates, and dry machining to avoid thermal deformation. For steel, prioritize spindle rigidity and thermal management. Our standard tolerance for aerospace-grade parts is ±0.005mm using these machines – achievable only with precision CNC mills, not cutting tables.

Let me know if you need vendor-specific quotes or process validation for your application!

From CAD to Part: The Process

Honyo Prototype – CNC Cutting-Table Workflow

(what happens to your 2-D/2.5-D part after you press “upload”)

-

Upload CAD

• Accepted formats: .dxf, .dwg, .ai, .step, .igs, .pdf, .svg (native Fusion/SolidWorks files auto-convert).

• Cloud parser instantly checks: closed contours, self-intersections, layer count, minimum slot width, minimum bridge/tab size for the cutting table.

• You pick material, thickness and quantity from the drop-down or leave it “open” for AI recommendation. -

AI Quote (≤ 30 s)

• Neural-net estimator trained on 1.8 M real jobs: maps geometry ➞ cutting length, pierce count, heat-affected zone, nest efficiency on 1500 × 3000 mm sheet.

• Real-time stock check: laser, plasma, water-jet, or knife table availability.

• Dynamic pricing: material cost + machine time + edge quality class + lead time.

• One-click to accept or iterate (change quantity, material, or edge quality). -

DFM (Design-for-Manufacture) – 15 min human sign-off

• Application engineer opens the AI pre-check report: kerf width, taper allowance, tab/bridge placement, grain direction for cosmetic faces.

• Auto-fixes: open contours closed, micro-loops added to prevent corner over-burn, lead-ins repositioned to avoid part tipping.

• Customer receives 3-D PDF + annotated drawing; approval is a single e-signature.

• If part needs post-cut machining (countersink, counterbore, tapping) it is routed to the “Cut-then-CNC” queue and the quote is updated. -

Production – CNC Cutting Table Cell

a. Nesting & NC generation

– SigmaNEST auto-nests on 5 × 10 ft sheet, common-line cuts where possible, rotates to match grain or coating direction.

– NC code sent to the appropriate table:

• Fiber laser (≤ 20 mm steel, ±0.05 mm)

• High-definition plasma (≤ 50 mm, ±0.2 mm)

• Water-jet (multi-head, no HAZ, ±0.08 mm)

• Oscillating-knife (composites, foams, gaskets)

b. Setup

– Fiducial camera aligns sheet to ≤ 0.02 mm; automatic nozzle/calibration cycle.

– First-article contour laser-scanned; deviation < 0.05 mm triggers green light, else auto-correct offset.

c. Lights-out cutting

– Part extraction robot removes cut pieces onto rubber-tipped sorting table; micro-tabs keep small parts in skeleton until pick-up.

– Slag/grain removal: plasma parts go through brush-deburr; laser parts bypass unless requested.

d. In-line QA

– 2-D Keyence projector measures every 5th part; Cpk data uploaded to traveler.

– Edge roughness Ra checked against ISO 9013 class; re-cut or secondary finishing scheduled if out of spec. -

Delivery

• Parts ultrasonically cleaned, VCI bagged or foam-separated, labeled with QR code that links back to digital traveler (material cert, heat number, inspection report).

• Same-day courier in Shenzhen/Dongguan; global DHL/UPS before 5 p.m. ships that night.

• Tracking dashboard updates every checkpoint; e-mail + WeChat push when parts leave Honyo and again on final delivery scan.

Typical elapsed time (stock material, ≤ 50 parts):

Upload ➞ AI Quote 30 s

Quote accept ➞ DFM approval 2 h

Approval ➞ parts out the door 24 h

Door-to-door in EU/US 72–96 h total.

Start Your Project

Here are professional, benefit-driven CTA options for your CNC cutting table services—perfect for websites, emails, or marketing materials. All include your brand, contact details, and Shenzhen factory advantage:

🏭 Option 1 (Concise & Action-Oriented)

Precision CNC Cutting Tables, Made in Shenzhen.

Get custom solutions built to your specs—contact Susan Leo today:

info@hy-proto.com

🔧 Option 2 (Problem-Solution Focused)

Struggling with cutting accuracy or inefficiency?

Honyo Prototype’s Shenzhen factory delivers precision CNC cutting tables that maximize throughput and minimize waste.

→ Email Susan Leo: info@hy-proto.com

🌏 Option 3 (Global Reach + Local Expertise)

World-Class CNC Cutting, Powered by Shenzhen Manufacturing.

As a Senior Manufacturing Engineer at Honyo Prototype, I ensure every table meets exacting quality standards.

Partner with us—contact Susan Leo at info@hy-proto.com

✅ Why these work:

- ✨ Highlights key differentiators: “Shenzhen factory” signals cost efficiency, fast turnaround, and quality control.

- 💡 Focuses on customer benefits (precision, efficiency, custom solutions) instead of just features.

- 👔 Professional tone aligns with Honyo Prototype’s engineering expertise (e.g., “Senior Manufacturing Engineer” in Option 3 adds credibility).

- 📧 Clear, scannable contact info—no fluff, just actionable steps.

Use Case Tips:

– Website banner: Option 1 (short and punchy).

– Email signature: Option 3 (adds authority).

– Trade show booth: Option 2 (addresses pain points immediately).

Let me know if you’d like versions tailored for social media, brochures, or specific industries (e.g., aerospace, automotive)! 🔧

🚀 Rapid Prototyping Estimator