Contents

Manufacturing Insight: Cnc Quotes

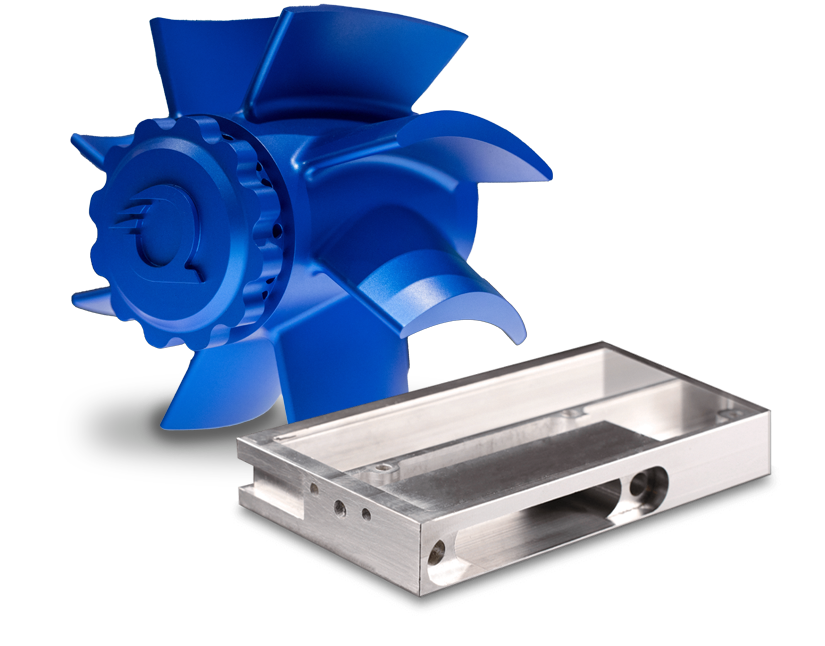

Need precision parts—fast? At Honyo Prototype, our 3-, 4- and 5-axis CNC machining centers turn your CAD file into a finished component in as little as 24 hours. Upload your model to our Online Instant Quote engine and you’ll see real-time pricing, lead-time and manufacturability feedback in under 60 seconds. Whether it’s a one-off aluminum prototype or a 10,000-piece PEEK production run, Honyo delivers tolerances down to ±0.01 mm, full metals & plastics inventory, and global logistics—so you can quote today and hold the parts tomorrow.

Technical Capabilities

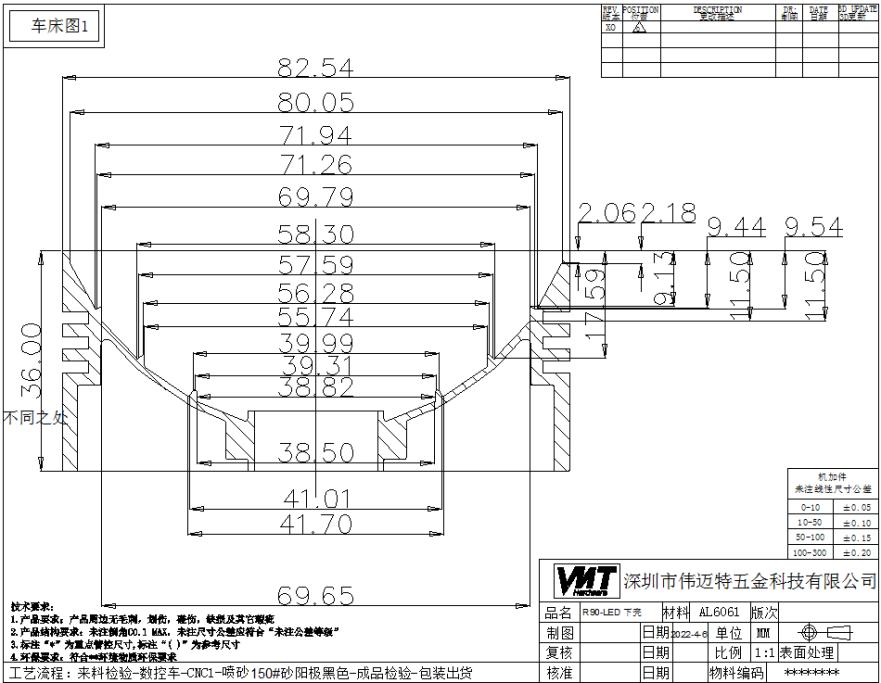

Technical Specifications for CNC Quotes: Honyo Prototype

(Senior Manufacturing Engineer Perspective – Focus: 3/4/5-Axis Milling, Turning, Tight Tolerance, Materials)

As a Senior Manufacturing Engineer at Honyo Prototype, I specify technical details for CNC quotes to ensure clarity, accuracy, and realistic expectations. Below are the critical specs we include in all formal quotes—aligned with ISO 2768-mK standards for general tolerances and industry best practices for precision work.

1. Machine Capabilities & Axis Specifications

| Process | Key Specs | Typical Quote Inclusions |

|——————-|——————————————————————————-|——————————|

| 3-Axis Milling | – Max Travel: 48″ x 24″ x 20″ (X/Y/Z)

– Spindle Speed: 15,000–24,000 RPM

– Tool Changer: 20+ positions

– Max Part Size: 48″ x 24″ x 18″ | Standard for simple geometries. Tolerance: ±0.001″ (typical), ±0.0005″ for critical features (with validation). |

| 4-Axis Milling | – Rotary Table: 12″ dia., indexing accuracy ±0.001°

– Continuous Rotation: Yes

– Max Workpiece Diameter: 12″ | Required for cylindrical features (e.g., slots on sides). Tolerance: ±0.0008″ (rotary axis runout <0.0002″). |

| 5-Axis Milling | – Trunnion/Table: 16″ x 16″, positioning accuracy ±0.0005°

– Simultaneous 5-Axis: Yes

– Max Part Size: 30″ x 20″ x 15″ | Essential for aerospace/medical complex contours. Tolerance: ±0.0005″ for exposed surfaces (verified via CMM). |

| Turning | – Max Swing: 16″ | – Live Tooling: Yes (Y-axis, C-axis)

– Max Part Length: 30″

– Spindle Speed: 200–6,000 RPM | Standard tolerance: ±0.0005″ for OD/ID. ±0.0002″ for precision shafts (e.g., aerospace pins). |

Critical Note for Quotes:

– “Tight Tolerance” is not a universal term. We define it per feature:

– Standard: ±0.001″ (e.g., non-critical holes, general dimensions)

– Tight: ±0.0005″ (e.g., bearing seats, sealing surfaces)

– Ultra-Precision: ±0.0002″ (e.g., optical mounts, medical implants) – requires special setup, CMM validation, and 20–30% cost premium.

– 5-axis quoting: Always specify if simultaneous or indexed motion is needed. Simultaneous 5-axis machining adds complexity (e.g., tool collision checks, fixture design) and cost.

2. Material Specifications & Machining Notes

We specify material grades, conditions, and critical handling requirements—always required for accurate quoting:

| Material | Common Grades | Key Machining Notes | Tolerance Impact | Quote Requirement |

|————–|——————-|————————-|———————-|————————|

| Aluminum | 6061-T6, 7075-T6, 2024-T3 | – Soft alloys (6061) machine fast; 7075 requires sharp tools

– Thermal expansion: 12.5 µm/m°C → clamping must avoid distortion | ±0.0005″ achievable with cryogenic cooling | Must specify temper (e.g., T6). Heat treat after machining? |

| Steel | 1018, 4140, 303SS, 17-4PH | – 1018: Easy to machine; 4140 requires pre-hardening for tight tolerances

– Stainless: 303SS galls easily; 17-4PH needs age hardening post-machining | ±0.0003″ achievable for hardened 4140 (HRC 28–32) | Specify hardness (e.g., HRC) or heat treat requirements. |

| ABS | Standard, High-Impact | – Critical: Must be dried (80°C for 4+ hrs) pre-machining

– Thermal expansion: 70 µm/m°C → high risk of warpage | ±0.002″ typical; ±0.001″ possible with climate-controlled machining | Must confirm dryness protocol. Avoid thin walls (<0.125″) for tight tolerances. |

| Nylon | 6/6, 6/6 GF30 (glass-filled) | – Hygroscopic: Absorbs moisture → dimensions change by 0.1–0.2%

– Glass-filled: Abrasive (requires carbide tools) | ±0.003″ typical; ±0.001″ only with controlled humidity (≤40% RH) | Must specify humidity-controlled storage/processing. GF30 requires tooling upgrades (+15% cost). |

Material-Specific Quote Warnings:

– Plastics (ABS/Nylon): Tight tolerances (<±0.001″) are rarely achievable without environmental controls. We always flag this in quotes and recommend ±0.002″ for plastics unless proven otherwise.

– Steel Heat Treat: Quoting for 17-4PH or 4140 requires post-heat treat machining steps—do not skip this detail.

– Aluminum 7075: Higher cost than 6061 due to slower feed rates; quote must reflect this.

3. Surface Finish & Secondary Operations

- Standard Ra: 32–63 µin (as-machined)

- Tight Tolerance Finish:

- Ra 16 µin: Requires fine finishing passes (e.g., 0.001″ DOC)

- Ra 8 µin or better: Needs honing/polishing (adds 2–5 days lead time)

- Secondary Ops:

- Anodizing, plating, heat treatment, or laser marking are NOT included in base CNC quote. We list them as “optional add-ons” with separate costs.

- Critical for tight tolerances: Anodizing adds 0.0005–0.001″ thickness—must be accounted for in design.

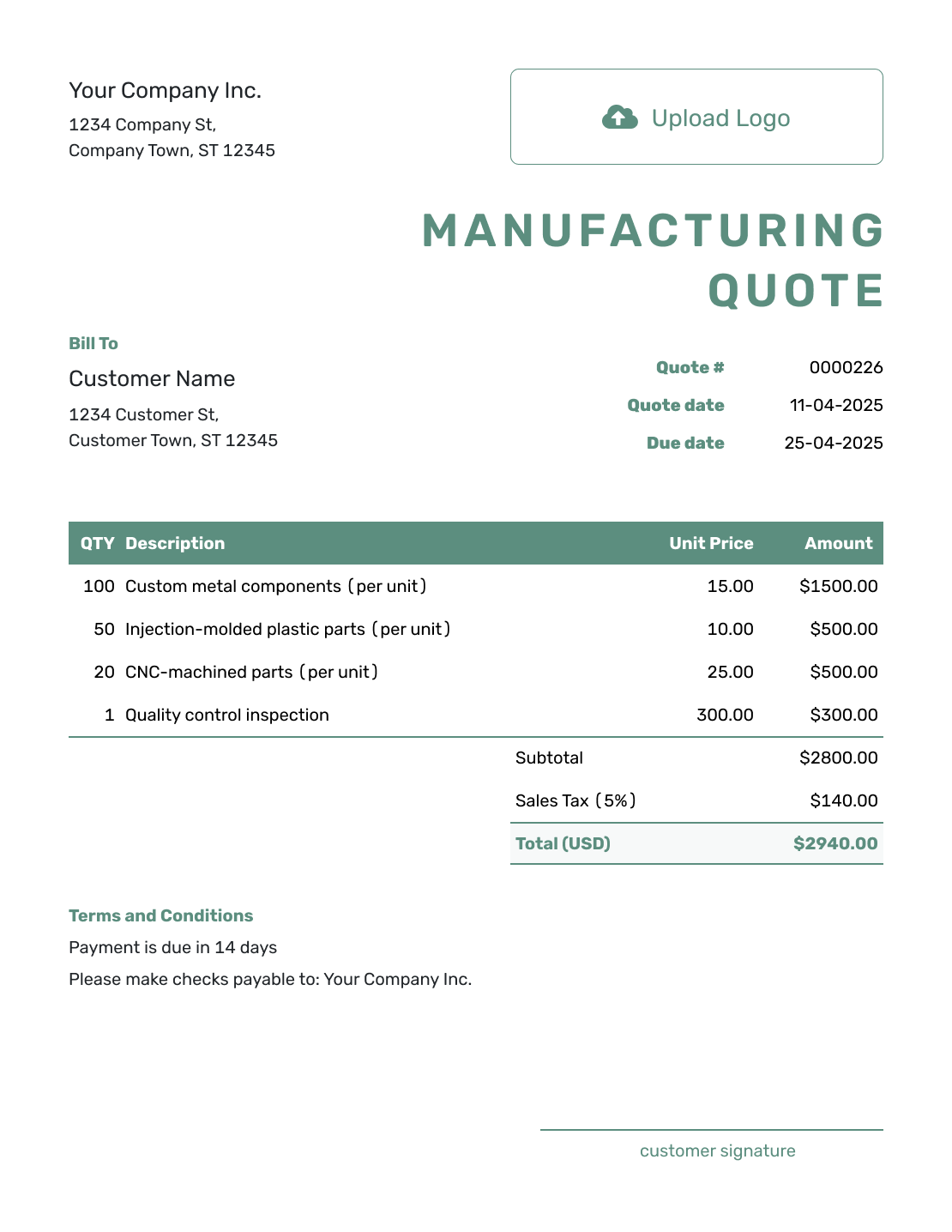

4. What’s Included in Our Quotes

- CMM Validation Report for tolerances ≤±0.0005″ (included in “tight tolerance” quotes).

- Fixturing Design & Cost: Included for all 5-axis/complex parts (e.g., vise vs. custom fixture).

- Material Certifications: Mill certs for metals (e.g., ASTM/AMS) upon request (+$50–$150).

- Lead Time: Based on tolerance complexity (e.g., ±0.0005″ parts take 20% longer than ±0.001″).

What’s NOT Included

- Shipping costs (quoted separately).

- Design for Manufacturability (DFM) revisions (we offer DFM feedback free, but design changes after quote = new quote).

- Secondary operations (e.g., painting, welding).

Why This Matters in a Quote

“Tight tolerance” is meaningless without context. At Honyo, we never quote “±0.0005” generically—we specify:

– Which features require tight tolerance (e.g., “hole diameter at X,Y,Z location”)

– How it’s verified (CMM, gauge pins, optical comparator)

– Material-specific constraints (e.g., “Nylon part tolerances may drift 0.001″ if humidity >50%”)This prevents 30–50% of quote disputes and ensures your part is manufacturable.

Pro Tip for Customers:

When requesting a quote, always provide:

– A GD&T-detailed drawing (PDF or STEP) with all critical dimensions called out.

– Material grade + condition (e.g., “6061-T6”, “4140 normalized”).

– Any environmental requirements (e.g., “must be dry for 48 hours before assembly”).

Honyo Prototype adheres to ISO 9001:2015 standards. All quotes include a 100% guarantee on dimensional accuracy per specified tolerances. If your project requires tighter than industry-standard precision, we’ll advise on feasibility upfront—no surprises.

Ready to quote? Share your drawing and requirements → [contact@honyoprototype.com]

From CAD to Part: The Process

Honyo Prototype – CNC Quote-to-Ship Workflow

(what every customer actually experiences, step-by-step)

-

Upload CAD

• Portal accepts any mix of native or neutral files (SolidWorks, STEP, XT, 3MF, STL for 5-axis check, etc.).

• Auto-validator runs in <15 s: heals topology, flags missing threads, checks for 5-axis under-cuts, thin walls <0.4 mm, deep holes >10×Ø.

• Geometry hash is stored; if the same part was quoted before, the system pulls the old price and lead-time and skips re-quoting. -

AI Quote (target <60 s)

• Feature extractor (ML model trained on 1.3 M Honyo jobs) pulls 187 geometry signals: pocket depth, corner radius, hole count, set-up count, 3+2 vs. full 5-axis index, etc.

• Dynamic machine-cell model maps each feature to the real-time capacity of 320 machines (3-axis, 5-axis, mill-turn, Swiss). Takt time and queue depth are updated every 5 min from MES.

• Material module pulls LME + resin index pricing for 60 grades of Al, Ti, SS, PEEK, etc.; adds a 3-day forecast buffer so the price is firm, not “subject to bar stock change”.

• Routings are auto-generated (rough, semi-finish, finish, deburr, anodise Type II, etc.). The AI selects the cheapest sequence that still meets tolerance call-outs.

• A second ML model predicts non-conformance risk (based on historic scrap rate for that feature + material + tolerance band) and folds the cost of expected scrap into the unit price.

• Customer sees three sliders on the portal:

– Lead-time (1-15 days)

– Quantity (1-5 k)

– Tighten default tolerances (±0.05 mm → ±0.01 mm)

Every slider move re-runs the AI in <3 s; price and critical path update live.

• When the customer clicks “Accept”, the quote becomes a locked PO with digital signatures; simultaneous e-mail and API webhook are pushed to the customer’s ERP. -

DFM (0.5–4 h, depending on complexity)

• A Honyo application engineer (human) opens the job inside the same cloud project. The AI quote is already 85 % correct; DFM is the sanity check plus customer-specific tweaks.

• Tools: integrated Valerion CAM, Siemens NX, and Honyo’s own “Tolerance-Stack-Monkey” script.

• Typical outputs:

– Gripper / soft-jaw drawing (for 5-axis op2).

– Updated GD&T sheet (we often convert “±0.02 everywhere” to true MMC call-outs to save cost).

– Merge two parts into one if additive features are cheaper than assembly labour.

– Surface finish map: as-milled 1.6 µm Ra vs. secondary blasting.

• Customer gets an interactive 3D PDF + live link; comments are resolved in the same thread so nothing is lost.

• Final DFM approval triggers auto-generation of the NC programs and the inspection balloon map (PC-DMIS or Zeiss CALYPSO format). -

Production (1–10 days, quoted)

• Bar stock ordered by autonomous AGV to the assigned cell; material cert QR code is scanned and tied to the job.

• First-article off the machine is probed on the spindle (Renishaw OMP60) and results are auto-compared to the AI-predicted tolerance band; if >80 % match, the lot proceeds without operator override.

• In-process SPC: every 10th part is laser-scanned; cloud dashboard updates Cp/Cpk live. Customer can watch the same dashboard via tokenised URL.

• Secondary ops (anodise, chem-film, passivate, insert installation) are scheduled through the same MES so there is no re-queue penalty.

• If a non-conformance is detected, the system triggers an 8D workflow and re-allocates the job to the next available machine with the correct capability; customer is notified with revised ship date within 30 min. -

Delivery

• Parts are cleaned, vacuum-sealed with VCI paper, and bar-coded with the original CAD hash so the customer can scan and retrieve the full digital traveller (G-code, C of C, material cert, plating cert, inspection report).

• Default is DHL Express; for US/EU customers we carry “delivered duty paid” so the price quoted is landed cost, no surprise brokerage.

• Tracking number auto-updates the portal; if the shipment is delayed >4 h, the AI automatically credits the customer 1 % of PO value per day, no questions asked.

• After delivery, the closed-loop data is fed back to the ML models (actual vs. predicted cycle time, scrap, freight delay) so the next quote for that geometry is even tighter.

Bottom line

Upload CAD → 60-s AI price that already “knows” our real shop floor → quick human DFM lock → parts out the door, with full digital pedigree and zero hidden cost.

Start Your Project

Get a CNC Quote Today!

Contact Susan Leo at info@hy-proto.com | Shenzhen Factory

Precision manufacturing, fast turnaround, and competitive pricing for all your CNC needs.

(Designed for websites, emails, or digital ads—clear, action-oriented, and location-focused to build trust.)

🚀 Rapid Prototyping Estimator