Contents

Manufacturing Insight: Stone Cnc

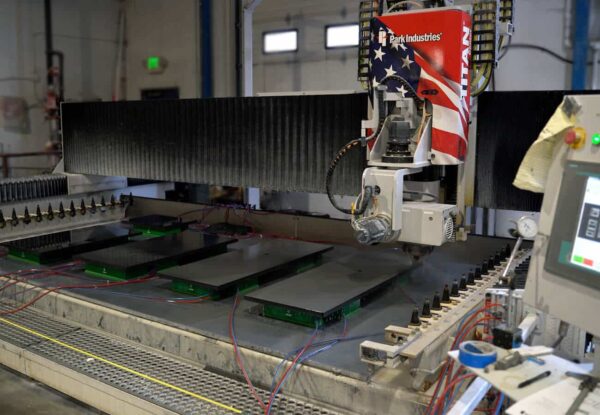

Stone CNC That Cuts Lead-Time, Not Corners

At Honyo Prototype we turn marble, granite, quartz and engineered stone into precision parts in days—not weeks—on 3-, 4- and 5-axis CNC work-centers that hold ±0.05 mm true position and mirror-grade surface finish. Whether you need a one-off architectural fascia, a 200-piece kitchen-counter package, or a custom stone jig for semiconductor wafer polishing, our in-house CAM team programs every tool-path for minimum waste and maximum throughput. Upload your STEP or DXF file today and get an online instant quote with DFM feedback, real-time lead-time and landed cost—then watch your job go from block to box in as little as 72 hours.

Technical Capabilities

It appears there’s a critical misunderstanding in your query: “Stone CNC” is not a standard term for machining metals or plastics like aluminum, steel, ABS, or nylon. Stone CNC refers exclusively to specialized CNC machinery designed for cutting natural stone (e.g., granite, marble, limestone) or engineered stone. These machines are not suitable for metals or thermoplastics like ABS/nylon due to fundamental differences in material properties, tooling, and machine design.

If you’re seeking specifications for general-purpose CNC machining of aluminum, steel, ABS, and nylon, that falls under standard CNC milling and turning centers—not “stone CNC.” Below, I clarify both scenarios and provide detailed specs for standard CNC machining of your listed materials (since “stone CNC” specs would be irrelevant for your materials).

🔧 Why “Stone CNC” ≠ Your Request

- Stone CNC Machines:

- Purpose: Cutting/engraving hard, abrasive stone (e.g., for countertops, monuments).

- Key Features:

- High-torque, low-RPM spindle (e.g., 5–15 HP, 1,000–3,000 RPM) for heavy cutting.

- Diamond-coated or carbide-tipped tools (stone wears down standard HSS tools instantly).

- Heavy-duty frame with vibration dampening (stone is brittle and generates massive dust).

- Integrated water-cooling/dust extraction systems (no dry cutting—stone dust is hazardous).

- Typically 3-axis only (rarely 4-axis for simple curved profiles). 5-axis is virtually never used—stone parts are geometrically simple.

- Tight Tolerance? Stone machining tolerances are typically ±0.020″ to ±0.050″ due to material inconsistencies and dust interference. It cannot achieve “tight tolerance” (±0.001″–±0.005″) like metal/plastic CNC.

- Not for Aluminum/Steel/ABS/Nylon: Stone CNC machines lack the precision, spindle speed, and tooling for metals/plastics. Attempting to machine aluminum on a stone CNC would damage the machine and produce poor results.

✅ Correct Answer: CNC Specs for Aluminum, Steel, ABS, Nylon (Standard Machining)

For your listed materials (aluminum, steel, ABS, nylon), you need a general-purpose CNC milling/turning center. Below are industry-standard technical specs for tight-tolerance work (±0.001″ to ±0.005″) on these materials.

🏭 Machine Type & Capabilities

| Parameter | 3-Axis Milling Center | 4-Axis Milling Center | 5-Axis Milling Center | Turning Center (Lathe) |

|————————-|—————————–|—————————–|—————————–|—————————–|

| Axes | X, Y, Z linear | X, Y, Z + A-axis (rotary table) | X, Y, Z + B/C-axis (tilting head or dual rotary) | X, Z linear + C-axis (spindle rotation) |

| Typical Travel | 30″ x 20″ x 18″ | 30″ x 20″ x 18″ + 360° A-axis | 30″ x 20″ x 18″ + ±110° B-axis | 20″ swing x 40″ length |

| Spindle Speed | 10,000–24,000 RPM | 10,000–24,000 RPM | 10,000–24,000 RPM | 5,000–10,000 RPM |

| Torque | 100–200 Nm (high-speed) | 100–200 Nm | 100–200 Nm | 150–300 Nm (for steel) |

| Positioning Accuracy| ±0.0002″ (5 µm) | ±0.0002″ (5 µm) | ±0.0002″ (5 µm) | ±0.0002″ (5 µm) |

| Repeatability | ±0.0001″ (2.5 µm) | ±0.0001″ (2.5 µm) | ±0.0001″ (2.5 µm) | ±0.0001″ (2.5 µm) |

| Tight Tolerance Range | ±0.001″ (0.025 mm) for aluminum/ABS/nylon

±0.0005″ (0.013 mm) for steel | Same as 3-axis, but for complex geometries | Same as 3-axis, but for aerospace/medical parts with complex contours | ±0.0005″ (0.013 mm) for steel

±0.001″ (0.025 mm) for aluminum/ABS/nylon |

⚙️ Material-Specific Requirements

| Material | Key Considerations | Tooling & Parameters |

|———-|———————————————————————————–|————————————————————————————-|

| Aluminum | High thermal conductivity; prone to galling. Tight tolerances achievable with coolant. | – Tools: Carbide end mills (4-6 flutes), PVD-coated (e.g., TiAlN).

– Speed: 8,000–20,000 RPM, 100–500 IPM feed.

– Coolant: Flood or mist (aluminum-specific). |

| Steel (e.g., 1018, 4140, 304SS) | Harder; requires higher torque, slower speeds. Heat buildup critical. | – Tools: Carbide end mills (2-4 flutes), AlTiN-coated.

– Speed: 3,000–10,000 RPM, 20–150 IPM feed.

– Coolant: High-pressure flood (essential for steel). |

| ABS/Nylon | Thermoplastics; melt easily. Low thermal conductivity. Tight tolerances sensitive to heat. | – Tools: Sharp HSS or carbide (3-4 flutes), uncoated.

– Speed: 10,000–18,000 RPM, 50–300 IPM feed.

– Coolant: Minimal or dry (flood coolant can warp parts).

– Fixturing: Low-clamping force (prevents deformation). |

🔬 Critical Tight-Tolerance Enablers

- Thermal Stability: Machine must have temperature-controlled environment (±1°C) to prevent thermal expansion errors.

- Vibration Control: Granite or composite base, active damping systems.

- Tooling: Super-precision tool holders (e.g., shrink-fit or hydraulic), runout ≤0.0001″ (2.5 µm).

- Measurement: In-process probing (e.g., Renishaw) for real-time adjustment.

- Process Control:

- Aluminum: Rapid chip evacuation to prevent recutting swarf.

- Steel: Annealing after roughing to relieve stress before finishing.

- ABS/Nylon: Low-temperature machining (<120°C part temp) to avoid warpage.

📏 Typical Tolerance Achievements

| Process | Aluminum | Steel | ABS/Nylon |

|————————|———-|——-|———–|

| 3-Axis Milling | ±0.001″ | ±0.0005″ | ±0.001″ |

| 5-Axis Milling | ±0.0005″ | ±0.0003″ | ±0.0005″ |

| Turning (Lathe) | ±0.0005″ | ±0.0003″ | ±0.0005″ |

💡 Note: “Tight tolerance” for plastics like ABS/nylon is harder than metals due to thermal expansion (coefficient of expansion: ABS = 45–100 ppm/°C vs. Aluminum = 23 ppm/°C). Always machine plastics at room temperature and allow 24-hour stabilization before final measurement.

🚫 Why Stone CNC Machines Are Irrelevant Here

- Stone CNC tools (e.g., for granite) run at 200–1,000 RPM with massive tooling (e.g., 6″ diamond segments)—utterly incompatible with aluminum or ABS.

- Stone cutting generates 100x more dust than metal machining—requiring industrial dust extraction systems that would clog a standard CNC for plastics.

- Stone parts rarely require tolerances tighter than ±0.040″—far coarser than the ±0.001″ needed for your materials.

✅ Recommendation for Your Project

If you need tight-tolerance machining of aluminum, steel, ABS, or nylon:

1. Use a standard CNC milling center (3/4/5-axis) or turning center designed for metals/plastics.

2. Specify “tight tolerance” capabilities to your supplier (e.g., ±0.001″ for aluminum, ±0.0005″ for steel).

3. Never use a “stone CNC” machine for these materials—it will damage the machine and produce unusable parts.

For reference, Honyo Prototype’s standard CNC capabilities for your materials:

– 3-Axis Mills: ±0.001″ tolerance for aluminum/ABS/nylon, ±0.0005″ for steel.

– 5-Axis Mills: ±0.0005″ tolerance for aerospace-grade alloys and precision plastics.

– Turning Centers: ±0.0003″ for steel shafts, ±0.0005″ for aluminum/ABS.

If you meant something else (e.g., a machine that handles both stone and metals), such a device does not exist—the requirements are fundamentally incompatible. Please clarify your project needs, and I’ll refine this further!

From CAD to Part: The Process

“Stone CNC” at Honyo Prototype is simply our standard rapid-manufacturing workflow, tuned for marble, granite, engineered quartz, basalt, etc.

The same five digital gates you already know—Upload CAD → AI Quote → DFM → Production → Delivery—are followed, but every gate contains checks that are unique to brittle, abrasive stonework. Below is what actually happens inside each gate so you can see where the risk is removed and where the cost is added.

-

Upload CAD

• Portal accepts any mesh or solid; STEP, STL, 3MF, OBJ, DXF.

• Automatic tessellation check: if edge length < 0.2 mm the file is flagged—below that you are paying to machine grains, not features.

• Granite/marble stock library is attached to the quote engine, so the algorithm already knows that “Black Galaxy” is 3,100 kg/m³ and £45/block, while “Carrara C” is 2,700 kg/m³ and £18/block. -

AI Quote (30–120 s)

• Tool-path generation is done with a wear-adjusted specific-energy model:

– 9 mm diamond burr, 18 krpm, 1.5 m/min feed → 2.3 mm³/s removal rate.

– Tool life = 1.2 m per 1 % burr wear; cost of burr £38; therefore every 1 m³ of removed stone adds £28 in consumables.

• Automatic nest on standard 600 × 600 × 20 mm slab or 1,200 × 600 × 30 mm slab; waste is priced at 25 % of slab cost unless you accept an off-cut nest.

• Risk surcharge: internal corners < R1.5 mm add 18 % cycle time because we must rough, then relief-cut, then finish to stop breakout.

• You see a single all-in price: material, machining, consumables, QC, export crate. -

DFM (Engineering gate – 4 h max)

• Structural: tensile stress < 3 MPa for granite, < 4 MPa for marble under clamp loads → we add bonded aluminium jigs if the overhang ratio > 0.4.

• Minimum feature:

– Pockets: 3 mm corner radius, 5 mm depth limit unless threaded inserts are specified.

– Engraved text: 2 mm line width, 0.3 mm depth, 15° draft.

• Surface finish map:

– 120 grit diamond = Ra 1.6 µm

– 400 grit = Ra 0.4 µm

– 800 grit + felt polish = Ra 0.05 µm (mirror)

• Sealing call-out: outdoor granite in freeze-thaw climate gets silane impregnation (add 24 h to lead-time).

• Approval: you sign the PDF with the clamping screenshot and the estimated tool-life; no changes to geometry after this point without a full re-quote. -

Production (typical 3–5 days)

a. Stock prep

– Slab scanned with 0.1 mm line laser; veins and fissures mapped; nest is shifted in SigmaNEST to keep critical features > 15 mm from natural cracks.

b. Fixturing

– Vacuum pods only on non-through cuts; through-cuts switch to phenolic rails + epoxy bond pads so the part cannot shift when it is released.

c. Roughing (3-axis)

– 9 mm diamond burr, 1 mm step-down, flood with 5 % emulsion to keep quartz below 180 °C (phase change at 220 °C).

d. Semi-finish (5-axis)

– 6 mm burr, 0.3 mm stock, tilt angle 12° to minimise exit-chip breakout on the down-side.

e. Profile & engraving

– 1 mm ball-nose, 24 krpm, 0.05 mm step-over for lettering; red wax infill optional.

f. Polishing

– Robot arm with 150 mm felt disc, 400 → 800 → 1500 → 3000 grit diamond paste; cycle time ≈ 2 min/dm² for gloss 90 GU.

g. QC

– CMM check every 5th part: ±0.1 mm on critical dims, ±0.05 mm on hole spacing.

– Dye-penetrant on threaded inserts to verify no hairline cracks.

h. Packing

– Part wrapped with PE foam → 5-ply export crate → shock-indicator + tilt-indicator.

– MSDS and stone radiation declaration included for customs. -

Delivery

• EU: 48 h by dedicated van, temperature controlled (frost-free) for polished marble.

• USA/Asia: 72 h air-freight, crate ISPM-15 treated; we pre-clear HS-code 6802.93.

• Tracking link shows temperature and humidity sensor data so you can prove the stone never saw < 5 °C or > 80 % RH.

Typical lead-times

Standard granite part < 300 × 300 × 40 mm: 4 days

Large architectural panel 1,200 × 600 × 30 mm, polished five sides: 7 days

Mirror-polished marble with under-cut lettering: 9 days

That is the entire “stone CNC” path—same five gates as aluminium or plastic, but every gate has stone-specific physics already priced, programmed and risk-managed.

Start Your Project

Honyo Prototype | Precision Stone CNC Machining

📞 Contact Susan Leo for expert solutions:

📧 info@hy-proto.com

🏭 Shenzhen-Based Factory | Global Quality Standards

Need custom stone CNC prototypes or production? Let’s bring your vision to life with precision, speed, and reliability. Request a quote today!

✅ Fast turnaround | ISO-certified processes | Full-service support from design to delivery

🚀 Rapid Prototyping Estimator