Contents

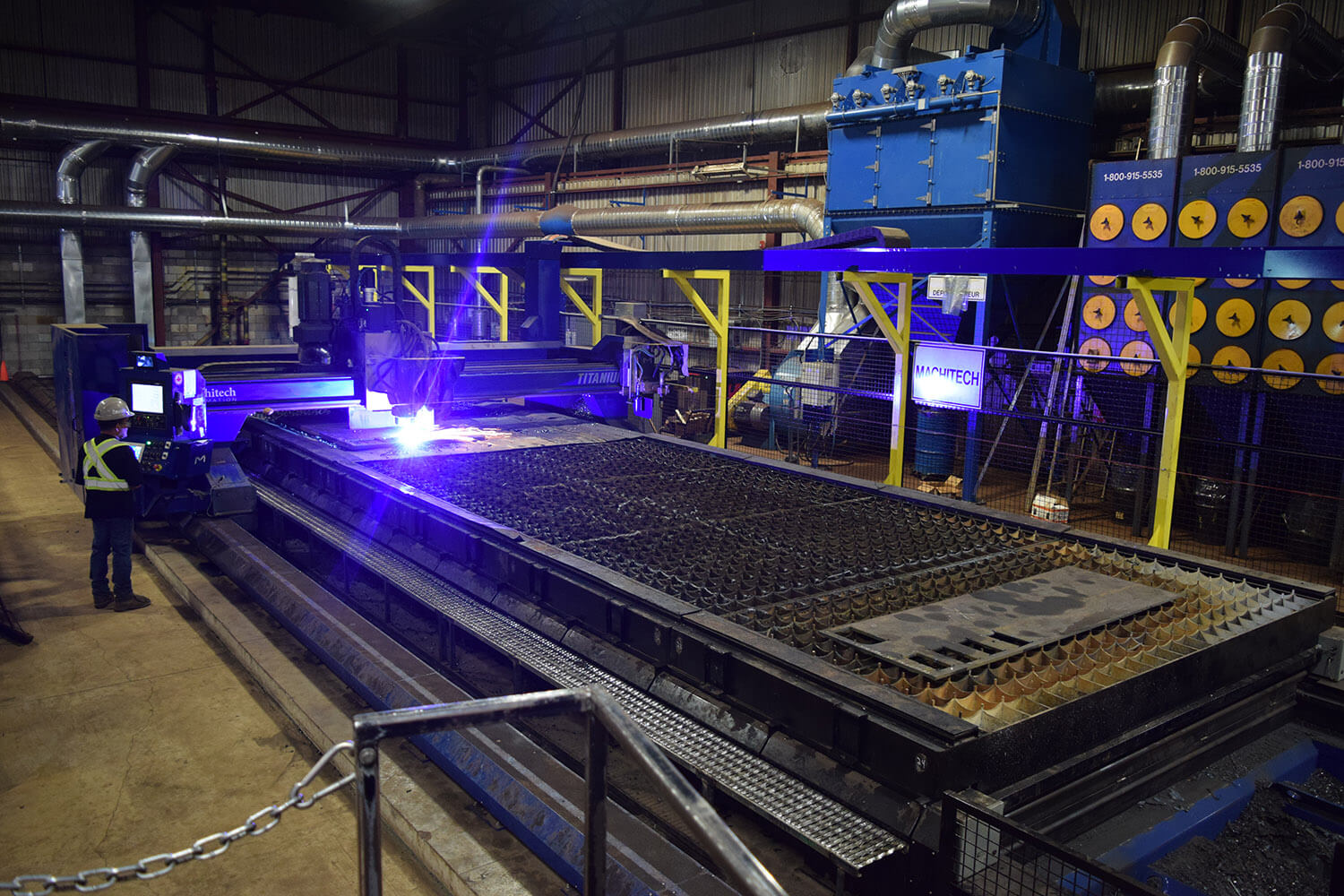

Manufacturing Insight: Cnc Cutting Table

CNC Cutting Table Technology Overview

CNC cutting tables represent a foundational technology in precision manufacturing, enabling the accurate profiling and contouring of sheet materials through computer-controlled motion systems. At Honyo Prototype, we deploy state-of-the-art CNC cutting tables to transform digital designs into physical components with exceptional repeatability and minimal human intervention. These systems utilize multi-axis coordinated movement—typically X and Y axes for planar cutting—driven by high-torque servo motors and guided by linear guideways. The integration of advanced motion control software ensures complex geometries are executed with micron-level accuracy, critical for aerospace, medical device, and automotive prototyping where dimensional integrity directly impacts functional performance. Unlike manual or semi-automated methods, CNC cutting tables eliminate operator-induced variability, significantly reducing scrap rates and accelerating time-to-prototype.

Honyo Prototype’s CNC Cutting Capabilities

Shenzhen Honyo Prototype leverages industrial-grade CNC cutting tables engineered for demanding prototyping and low-volume production workflows. Our systems accommodate a broad spectrum of materials, including aluminum alloys, stainless steel, titanium, engineering plastics, and composites, with thicknesses ranging from 0.5 mm to 25 mm. Precision is non-negotiable in prototyping; our tables consistently achieve positional tolerances of ±0.02 mm and surface finishes under Ra 1.6 µm, ensuring components meet stringent design specifications without secondary finishing. This capability is underpinned by rigorous machine calibration protocols and real-time thermal compensation systems that counteract environmental fluctuations in our climate-controlled facility. We prioritize rapid iteration cycles, allowing clients to validate designs through multiple physical iterations within compressed timelines—often delivering first-article parts in 72 hours from approved CAD data.

Honyo’s technical advantage extends to seamless integration with upstream and downstream processes. Our CNC cutting operations interface directly with client CAD/CAM files, supporting formats like STEP, IGES, and DXF, while automated tool-changing systems minimize non-cutting time. For complex assemblies, cut components feed directly into our in-house milling, turning, and finishing departments, ensuring holistic quality control from raw material to finished part. This integrated approach eliminates supply chain handoffs, reducing lead times by up to 40% compared to fragmented outsourcing models.

Key Technical Specifications

| Parameter | Value | Unit |

|——————–|——————-|———-|

| Max Working Area | 3000 × 1500 | mm |

| Positional Accuracy| ±0.02 | mm |

| Repeatability | ±0.01 | mm |

| Max Material Thickness | 25 | mm (Steel) |

| Spindle Speed Range| 6,000 – 24,000 | RPM |

Strategic Value for Prototyping

For engineering teams developing next-generation products, Honyo Prototype’s CNC cutting tables deliver more than dimensional accuracy—they enable design freedom. Complex organic shapes, intricate lattices, and tight-tolerance features that challenge conventional manufacturing become feasible, allowing innovation without process constraints. Our Shenzhen-based facility combines German-engineered hardware with localized technical expertise, providing clients a responsive partner for agile development. By investing in cutting-edge motion control and predictive maintenance systems, we ensure machine uptime exceeds 95%, directly supporting client project continuity. In an era where prototyping speed dictates market competitiveness, Honyo’s precision cutting capability transforms conceptual designs into validation-ready hardware with unmatched reliability. Partner with us to accelerate your path from sketch to functional prototype.

Technical Capabilities

CNC Cutting Table Technical Capabilities

Shenzhen Honyo Prototype offers advanced CNC cutting table services engineered for precision, efficiency, and repeatability across complex manufacturing applications. Our state-of-the-art 3-axis, 4-axis, and 5-axis CNC milling centers, coupled with high-performance CNC turning systems, enable us to produce intricate geometries and tight-tolerance components for aerospace, medical, automotive, and industrial clients. Each machine is calibrated and maintained to ensure optimal performance, delivering consistent surface finishes and dimensional accuracy across both prototyping and low-to-mid volume production runs.

Our 3-axis milling platforms provide robust material removal capabilities for prismatic and planar components, ideal for initial prototyping and functional testing. When greater complexity is required, our 4-axis systems introduce rotational indexing around the B-axis, enabling machining of features on multiple sides without manual repositioning. For the most geometrically challenging parts, our 5-axis simultaneous CNC milling centers allow toolpath articulation in real time across X, Y, Z, A, and B axes, minimizing setup changes and maximizing accuracy on contoured surfaces, impellers, molds, and structural components.

Complementing our milling capabilities, our CNC turning centers support bar-fed and chucking operations for cylindrical and symmetric parts, with live tooling options for mill-turn hybrid features. All systems are integrated with high-speed spindles, rigid probing, and in-process inspection, ensuring minimal deviation and high first-time yield.

Tolerance control is a cornerstone of our manufacturing philosophy. We maintain tight process controls to achieve precision down to ±0.005 mm (±0.0002″) for critical dimensions, supported by continuous environmental monitoring and statistical process control (SPC) protocols. Our quality assurance team employs coordinate measuring machines (CMM), optical comparators, and surface roughness testers to validate compliance.

The following table outlines our standard and precision tolerance capabilities by process and material:

| Process | Material Type | Standard Tolerance (mm) | Precision Tolerance (mm) | Typical Surface Finish (Ra, µm) |

|———————|———————|————————–|—————————|———————————-|

| 3-Axis Milling | Aluminum Alloys | ±0.05 | ±0.012 | 1.6 – 3.2 |

| 3-Axis Milling | Engineering Plastics| ±0.05 | ±0.025 | 1.6 – 3.2 |

| 4-Axis Milling | Stainless Steel | ±0.05 | ±0.012 | 1.6 – 3.2 |

| 5-Axis Milling | Titanium Alloys | ±0.05 | ±0.005 | 0.8 – 1.6 |

| CNC Turning | Carbon Steel | ±0.05 | ±0.01 | 1.6 – 3.2 |

| CNC Turning | Brass | ±0.05 | ±0.01 | 0.8 – 1.6 |

We process a wide range of engineering materials, including aluminum 6061, 7075, stainless steel 303, 304, 316, titanium Ti-6Al-4V, PEEK, Delrin, and polycarbonate. Each material is handled with optimized toolpaths, cutting parameters, and fixturing strategies to minimize distortion and ensure feature integrity. Our CNC cutting table operations are supported by in-house design for manufacturability (DFM) analysis, ensuring manufacturable, cost-effective solutions from concept to delivery.

From CAD to Part: The Process

CNC Cutting Table Production Workflow: From CAD to Precision Part

At Shenzhen Honyo Prototype, our CNC machining process for cutting tables integrates advanced digital workflows to ensure dimensional accuracy, structural integrity, and rapid turnaround. This standardized sequence—from initial inquiry to finished component—minimizes errors and optimizes manufacturability while adhering to strict aerospace and industrial tolerances. The three-phase workflow begins immediately upon receipt of client CAD data.

AI-Powered Quoting & Feasibility Assessment

Our proprietary AI engine analyzes submitted 3D models (STEP, IGES, or native CAD formats) within 2 hours, generating instant preliminary quotes. The system evaluates material utilization, machine time, toolpath complexity, and geometric constraints against our 5-axis milling, turning, and high-speed machining capabilities. Critical parameters like maximum work envelope (2000 x 1000 x 800 mm), positional accuracy (±0.005 mm), and surface finish ranges (Ra 0.8–6.3 μm) are auto-validated. This phase identifies immediate showstoppers such as undercuts beyond tool reach or features violating minimum wall thickness requirements, providing clients actionable feedback before formal order placement.

Engineering-Driven Design for Manufacturability (DFM)

Following quote acceptance, our engineering team conducts a rigorous DFM review. This collaborative step—often completed within 24 hours—examines structural elements specific to cutting tables, including gantry rigidity, linear rail mounting surfaces, and vacuum plenum integrity. We verify compliance with critical manufacturing parameters:

| Parameter | Minimum Value | Maximum Value | Material Constraint |

|————————–|—————|—————|————————–|

| Wall Thickness | 0.5 mm | N/A | Aluminum only |

| Hole Depth:Diameter Ratio| 1:1 | 12:1 | Steel/SS |

| Chamfer Size | 0.2 x 45° | 2.0 x 45° | All materials |

| Critical Tolerance Zone | ±0.01 mm | ±0.05 mm | Mounting interfaces only |

Engineers flag non-compliant features (e.g., thin ribs prone to chatter, insufficient draft for cast table bases) and propose optimized alternatives via marked-up PDFs. Client approval of DFM recommendations is mandatory prior to programming, ensuring alignment on functional requirements versus cost drivers.

Precision Production & Quality Verification

Approved designs enter production where our CNC cells execute tightly controlled processes. Cutting table components undergo sequential operations: rough milling for material removal, semi-finish passes for thermal stability, and final precision cuts using calibrated Renishaw probes. All critical datums—such as T-slot alignment surfaces (±0.02 mm over 1500 mm) or perpendicularity of vertical supports (0.03 mm/m)—are verified in-process via CMM-linked tool compensation. Post-machining, each assembly undergoes 100% dimensional inspection against the approved DFM document, with full FAI reports available. Final parts receive protective anodizing or powder coating per specification before shipment, with typical lead times of 7–12 days for complex welded-frame tables.

This integrated workflow—AI intelligence, engineering rigor, and monitored production—ensures cutting tables meet operational demands while reducing time-to-assembly by 30% compared to industry averages. Clients receive not just machined components, but validated solutions engineered for performance.

Start Your Project

Start Your Project with Precision CNC Cutting Tables from Shenzhen Honyo Prototype

When it comes to high-precision manufacturing, the foundation of success lies in reliable, durable, and accurately engineered equipment. At Shenzhen Honyo Prototype, we specialize in delivering advanced CNC cutting tables designed to meet the rigorous demands of modern fabrication, prototyping, and production environments. Whether you are working with metals, composites, plastics, or engineered wood, our CNC cutting tables provide the stability, accuracy, and integration capabilities required to elevate your manufacturing output.

Our CNC cutting tables are engineered with a focus on rigidity, thermal stability, and seamless compatibility with a wide range of CNC control systems. Each table is manufactured using high-grade materials and precision machining techniques to ensure flatness within ±0.02 mm over the entire surface, minimizing material warping and maximizing cut accuracy. Designed for both industrial-scale operations and agile prototyping workflows, these tables support automated tooling setups, vacuum hold-down systems, and modular fixturing options to streamline your production process.

We understand that every manufacturing project has unique requirements. That’s why our engineering team works closely with clients to customize table dimensions, T-slot configurations, surface coatings, and integration features based on specific application needs. From compact 600 × 600 mm tables for detailed prototyping to large-format 3000 × 1500 mm solutions for aerospace and automotive components, we deliver scalable solutions without compromising on quality.

To ensure long-term performance, our CNC cutting tables undergo rigorous quality control, including geometric accuracy testing, stress-relief treatment, and surface finish optimization. This commitment to excellence ensures consistent performance, reduced downtime, and extended tool life—critical factors in maintaining cost-efficiency and throughput.

Below are key specifications for our standard CNC cutting table offerings:

| Feature | Specification |

|—————————-|————————————————-|

| Material | High-strength cast aluminum or steel composite |

| Surface Flatness | ±0.02 mm over full surface |

| Standard Sizes (mm) | 600×600, 1000×500, 1200×600, 2000×1000, 3000×1500 |

| T-Slot Options | 14 mm, 18 mm, 22 mm (custom spacing available) |

| Maximum Load Capacity | Up to 1500 kg (depending on size) |

| Finish | Anodized or powder-coated for corrosion resistance |

| Compatibility | FANUC, Siemens, Mitsubishi, Mach3, LinuxCNC |

| Optional Features | Vacuum zones, dowel pin arrays, grid engraving |

Starting your next project with the right foundation is crucial. At Shenzhen Honyo Prototype, we combine engineering expertise with responsive support to ensure your CNC setup delivers optimal results from day one. If you’re ready to discuss your requirements or need a custom solution tailored to your workflow, contact Susan Leo directly at info@hy-proto.com. Our team is prepared to assist with technical specifications, lead times, and integration guidance to help you move from concept to production efficiently. Let us help you build with precision.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.