Contents

Manufacturing Insight: Plastic Snap Fit

Manufacturing Insight: Plastic Snap Fit Joints in CNC Machining

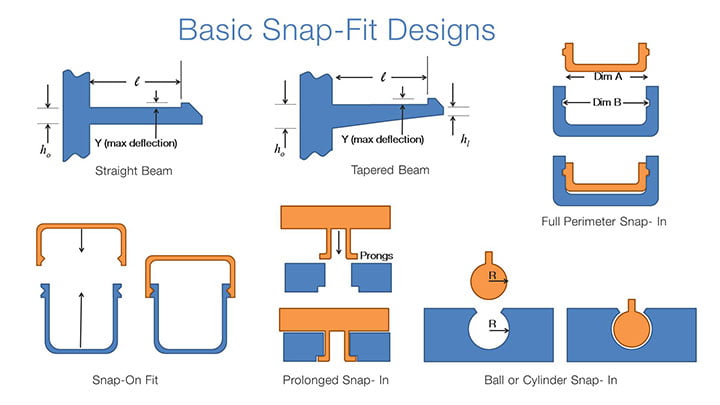

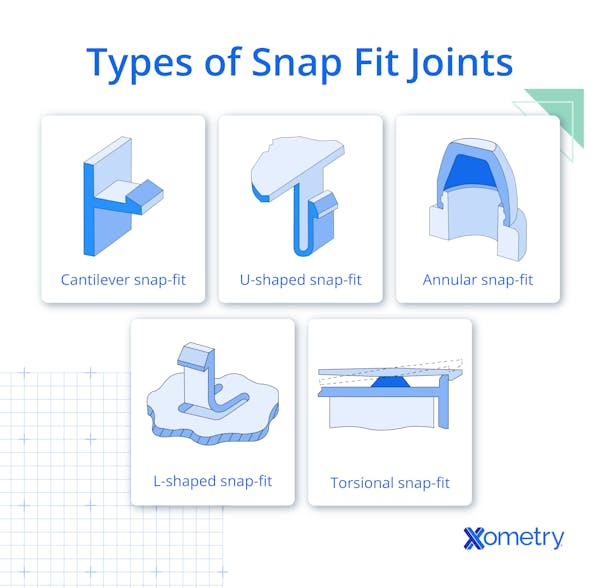

Plastic snap fit joints represent a fundamental and highly efficient assembly method in product design, eliminating the need for secondary fasteners, adhesives, or labor-intensive processes. These integrated mechanical interlocks rely on the elastic deformation of one component to engage with a mating feature, creating a secure connection upon return to the neutral state. While commonly associated with high-volume injection molding, the prototyping and low-volume production of functional snap fit assemblies present unique challenges where precision CNC machining delivers critical advantages. At Shenzhen Honyo Prototype, we specialize in transforming complex snap fit concepts into fully functional, test-ready prototypes and bridge production parts using advanced CNC techniques, ensuring design validation before costly tooling investment.

CNC machining excels for snap fit prototyping due to its ability to directly machine intricate geometries, including critical undercuts and precise engagement features, from solid plastic stock without requiring custom molds. This is paramount for snap fits, where minute deviations in critical dimensions like hook geometry, beam length, or clearance gaps directly impact assembly force, retention strength, and cycle life. Injection molded prototypes often suffer from draft angles, shrinkage variations, and parting line flash that mask true snap fit performance. CNC machining provides geometric precision unattainable in early-stage molded parts, revealing genuine mechanical behavior under load. Our 5-axis milling and turning centers achieve tolerances down to ±0.005 mm, essential for validating the delicate balance between sufficient retention force and acceptable assembly/disassembly effort required for reliable snap fit function.

The successful CNC machining of robust snap fits hinges on meticulous design for manufacturability alongside material selection. Key parameters must be optimized for the specific plastic’s flexural modulus and elongation at break. Below outlines critical design considerations and Honyo’s typical achievable ranges:

| Critical Parameter | Importance for Snap Fit Performance | Honyo Prototype Typical CNC Achievable Range |

| :———————– | :——————————————- | :——————————————- |

| Deflection Angle (θ) | Determines required strain; must stay below material yield point | 5° – 30° (Material Dependent) |

| Clearance Gap (C) | Critical for smooth engagement; insufficient gap causes high assembly force | 0.10 mm – 0.50 mm |

| Beam Length (L) | Governs flexibility; longer beams reduce stress but increase deflection | 2.0 mm – 15.0 mm |

| Hook/Undercut Depth (D) | Directly impacts retention strength | 0.20 mm – 1.50 mm |

| Wall Thickness (T) | Affects rigidity and stress concentration | 1.0 mm – 3.0 mm (Minimum for stability) |

Honyo leverages extensive material expertise with engineering plastics including ABS, PC, Nylon 6/6, POM (Acetal), and PP, understanding how each responds to elastic deformation during snap engagement. Our engineering team collaborates closely with clients during the design phase, providing DFM feedback specifically for snap fit features to prevent common failure modes like brittle fracture, creep-induced loosening, or excessive wear. Utilizing high-speed machining strategies and specialized toolpaths, we minimize stress concentrations in thin beam sections and ensure smooth surface finishes that reduce friction during assembly. All parts are machined under strict ISO 9001-controlled processes, with critical snap fit dimensions verified using calibrated CMMs and optical comparators. For designers requiring functional validation of snap fit mechanisms, Honyo Prototype delivers the dimensional accuracy, material integrity, and engineering insight necessary to de-risk assembly before committing to production tooling. Consult our manufacturing engineers to optimize your next snap fit design for CNC prototyping success.

Technical Capabilities

Plastic Snap Fit Manufacturing Capabilities

At Shenzhen Honyo Prototype, we specialize in high-precision CNC machining for plastic snap fit components, delivering robust, repeatable performance for assembly-critical applications. Our advanced 3, 4, and 5-axis milling centers, combined with precision turning capabilities, enable us to produce complex geometries with exacting tolerances required for reliable snap fit functionality. These components are widely used in consumer electronics, medical devices, and automotive interiors, where seamless assembly and long-term durability are essential.

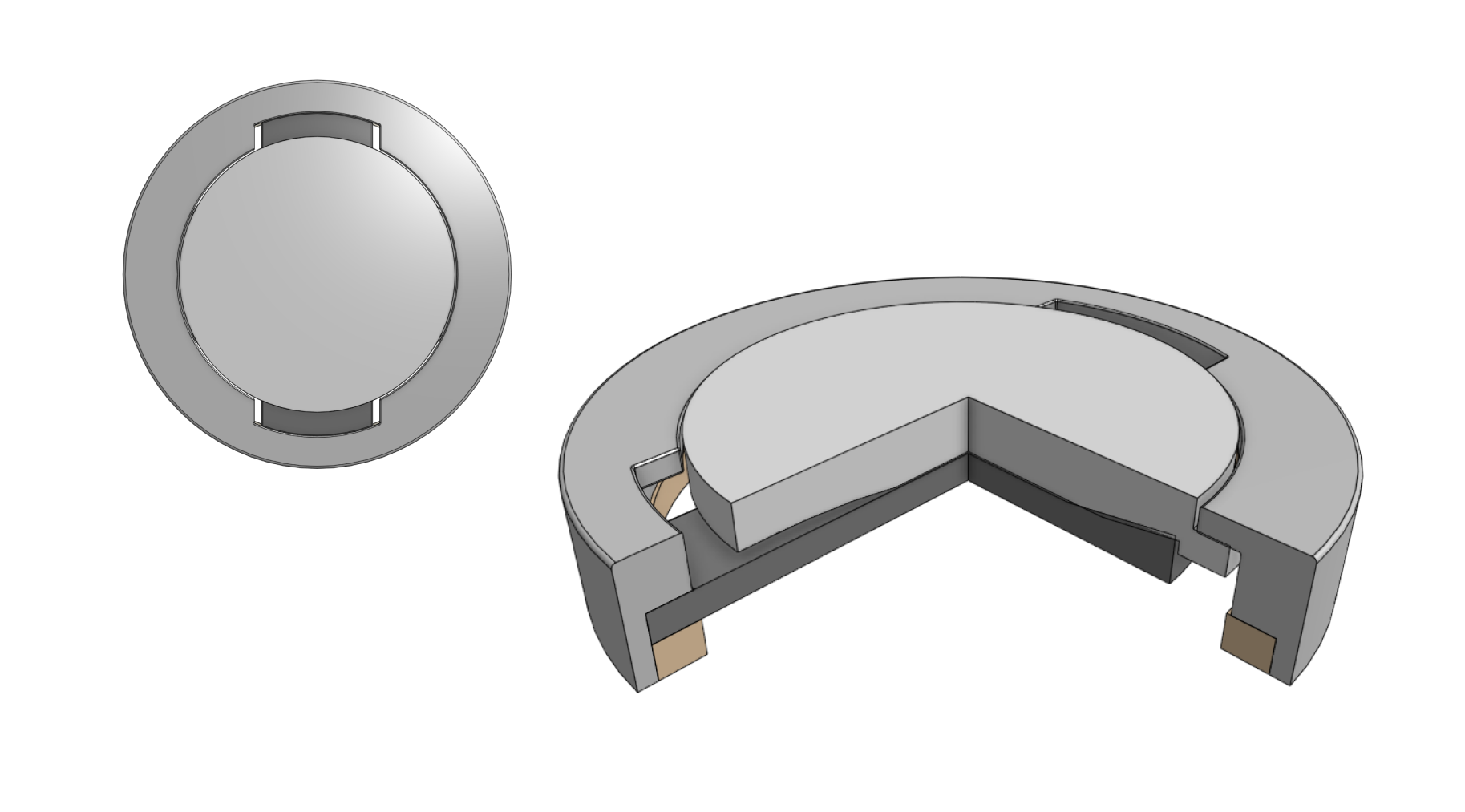

Our CNC machining processes are optimized for engineering-grade thermoplastics, allowing tight control over critical dimensions such as undercut profiles, wall thicknesses, and deflection zones. We apply adaptive toolpath strategies and high-speed machining techniques to minimize material stress and maintain dimensional stability—especially important when working with hygroscopic or thermally sensitive plastics. Our 5-axis milling systems provide full contouring capability, enabling undercuts and compound angles without secondary operations, which is crucial for one-piece snap fit designs. Similarly, our 4-axis indexing and 3-axis milling platforms support high-accuracy production of simpler yet tight-tolerance features.

For turning operations, we utilize precision Swiss-type and CNC lathes to produce cylindrical or symmetrical snap fit elements such as clips, rings, and bosses. These components benefit from sub-micron level roundness and concentricity control, ensuring consistent engagement and retention force. Tight tolerance machining down to ±0.025 mm is standard across all platforms, with process validation supported by in-house CMM and optical inspection systems.

The table below outlines our standard tolerance capabilities and compatible materials for plastic snap fit components:

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|——–|—————-|—————-|—————-|————-|

| Standard Tolerance (mm) | ±0.05 | ±0.05 | ±0.025 | ±0.025 |

| Minimum Wall Thickness (mm) | 0.8 | 0.8 | 0.6 | 0.5 |

| Minimum Undercut Depth (mm) | 0.5 | 0.5 | 0.4 | 0.4 |

| Surface Finish (Ra, μm) | 1.6 – 3.2 | 1.6 – 3.2 | 0.8 – 1.6 | 0.8 – 1.6 |

| Material | Typical Use | Machinability | Moisture Sensitivity | Recommended for Snap Fits? |

|———|————-|————–|———————-|—————————-|

| ABS | Enclosures, housings | Excellent | Medium | Yes |

| Nylon 6/6 | High-strength clips | Good | High | Yes (with pre-drying) |

| POM (Delrin) | Precision gears, clips | Excellent | Low | Highly Recommended |

| PC | Transparent components | Good | Medium | Yes |

| PP | Flexible hinges | Moderate | Low | Conditional |

| PEEK | High-temp applications | Moderate | Low | Yes (high-performance) |

We recommend POM (Delrin) for most snap fit applications due to its high stiffness, low friction, and excellent dimensional stability. For high-temperature or chemically aggressive environments, PEEK offers superior performance, albeit at higher material and machining costs.

Shenzhen Honyo Prototype combines technical expertise with rigorous quality control to ensure every plastic snap fit component meets functional and aesthetic requirements. Our engineering team supports DFM feedback to optimize part geometry, draft angles, and stress distribution—ensuring reliable assembly and long service life.

From CAD to Part: The Process

Plastic Snap Fit Production Process: CNC Machining Workflow

Shenzhen Honyo Prototype delivers precision plastic snap fit components through a rigorously controlled CNC machining workflow. This process ensures functional integrity, dimensional accuracy, and rapid turnaround from digital design to physical prototype or low-volume production part. Our methodology integrates advanced digital tools with expert manufacturing engineering, specifically optimized for the demanding requirements of snap fit geometries where precise interference and deflection control are critical.

The workflow initiates with the AI-Powered Quotation Phase. Upon receipt of the client’s CAD model (STEP, IGES, or native formats preferred), our proprietary AI engine performs an initial geometric and material analysis. It assesses part complexity, identifies potential high-risk features for snap fits (e.g., thin walls, sharp corners, critical engagement radii), and cross-references against our extensive material database and machine capability matrix. This enables generation of a highly accurate preliminary quote within hours, including estimated lead time and upfront identification of potential manufacturability flags requiring client discussion. Material suitability for the intended snap fit function (e.g., flexural modulus, creep resistance) is a key factor evaluated at this stage.

This transitions directly into the Engineering DFM Analysis Phase, the cornerstone of successful snap fit production. Our senior manufacturing engineers conduct a deep-dive Design for Manufacturability review, focusing explicitly on snap fit mechanics. We verify critical dimensions against material properties to ensure calculated deflection forces fall within functional limits without causing permanent deformation or excessive assembly force. Interference levels, wall thickness transitions, draft angles for ejection (if applicable to the machining strategy), and stress concentration points are meticulously analyzed. Potential issues like undercuts requiring complex fixturing or features approaching the limits of CNC precision for the chosen plastic are identified. Client collaboration is essential here; we provide actionable recommendations, such as minor geometry adjustments to improve manufacturability or material substitutions, before final approval. This phase prevents costly iterations and failed prototypes.

The CNC Machining Production Phase commences only after DFM sign-off. Material selection is critical; common choices include ABS for general purpose, POM (Acetal/Delrin) for superior fatigue resistance and low friction, or Nylon for high toughness. High-precision 3-axis or 4-axis CNC mills are employed, utilizing sharp, specialized carbide tooling and optimized, low-vibration toolpaths to achieve the stringent tolerances required for reliable snap engagement. Key process parameters are tightly controlled:

| Parameter | Typical Range for Snap Fits | Critical Impact |

| :—————– | :————————– | :———————————- |

| Dimensional Tolerance | ±0.05 mm to ±0.10 mm | Directly affects engagement force and reliability |

| Surface Roughness (Ra) | 0.8 µm to 3.2 µm | Influences assembly feel and wear life |

| Corner Radius | Min. 0.2 mm (Material Dep.) | Reduces stress concentration, prevents cracking |

Machining sequences prioritize minimizing part deflection and thermal effects. Critical snap features (beads, hooks, arms) are often machined in final operations with minimal material removal. Rigorous in-process inspection using calibrated CMMs or optical comparators verifies critical snap fit dimensions against the approved DFM-modified model. Final parts undergo functional validation, including assembly/disassembly testing to confirm force profiles and durability meet specifications before shipment. This integrated workflow ensures Shenzhen Honyo Prototype consistently delivers snap fit components that perform as engineered, directly from CAD.

Start Your Project

Designing Precision Plastic Snap Fits with CNC Machining at Shenzhen Honyo Prototype

When it comes to rapid prototyping and low-volume production of plastic components, plastic snap fits are a preferred mechanical assembly solution due to their ease of assembly, reduced need for fasteners, and cost-effective manufacturing. At Shenzhen Honyo Prototype, we specialize in CNC machining of high-precision snap fit designs, enabling engineers and product developers to validate form, fit, and function quickly and reliably.

Snap fits are integral features in plastic enclosures, housings, and consumer electronics, where repeated assembly and disassembly may be required. Achieving a reliable snap fit demands not only sound design principles but also tight-tolerance machining and expert material selection—capabilities that are central to our CNC machining services. Whether you’re developing a prototype for medical devices, IoT hardware, or industrial controls, our team ensures your snap fit joints are durable, repeatable, and manufacturable.

Our CNC machining process supports a wide range of engineering-grade thermoplastics, including ABS, PC, Nylon, POM (Delrin), and PP—each offering unique flexibility, strength, and fatigue resistance critical for successful snap fit performance. We machine parts with tolerances as tight as ±0.05 mm, ensuring precise alignment and consistent engagement of mating features. Surface finishes are tailored to your application, from as-machined to polished or textured, enhancing both aesthetics and functionality.

To assist in your design process, we provide key technical specifications for common materials used in snap fit applications. Below is a reference table summarizing mechanical properties relevant to snap fit performance:

| Material | Tensile Strength (MPa) | Flexural Modulus (GPa) | Elongation at Break (%) | Typical Applications |

|———|————————|————————|————————–|————————|

| ABS | 40–50 | 2.0–2.5 | 5–25 | Consumer electronics, enclosures |

| PC | 55–75 | 2.2–2.4 | 100–130 | Durable housings, medical devices |

| Nylon 6/6 | 70–85 | 2.5–3.0 | 30–60 | High-stress mechanical parts |

| POM (Delrin) | 60–70 | 3.0–3.5 | 15–40 | Precision gears, clips |

| PP | 30–35 | 1.3–1.8 | 100–600 | Flexible lids, living hinges |

Design for manufacturability (DFM) is critical when machining snap fits. Factors such as undercut geometry, wall thickness, strain during engagement, and draft angles must be carefully evaluated. Our engineering team offers free DFM feedback to optimize your design for CNC machining, minimizing stress concentrations and preventing premature failure.

If you’re ready to prototype your plastic snap fit component, we invite you to start your project with Shenzhen Honyo Prototype. Our fast turnaround, strict quality control, and material expertise ensure your functional prototype performs as intended.

Contact Susan Leo today at info@hy-proto.com to discuss your design, request a quote, or receive technical support. Let us help you turn your concept into a high-performing, manufacturable reality.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.