Contents

Manufacturing Insight: Titanium Auto Parts

Manufacturing Insight: Titanium Auto Parts via Precision CNC Machining

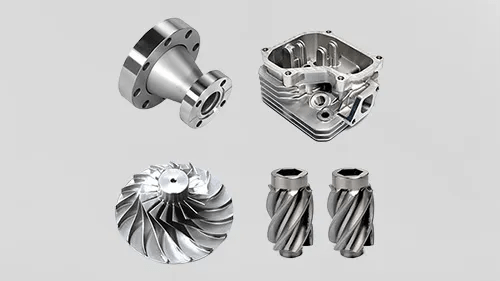

Titanium alloys represent a critical material advancement for high-performance automotive components, offering an exceptional strength-to-weight ratio and corrosion resistance essential for weight reduction, safety, and longevity in demanding applications like suspension arms, exhaust systems, and critical fasteners. However, machining titanium, particularly grades such as Ti-6Al-4V (Grade 5), presents significant technical hurdles distinct from common automotive steels or aluminum. Its low thermal conductivity leads to intense localized heat generation at the cutting zone, accelerating tool wear and risking material microstructural damage. High chemical reactivity at elevated temperatures promotes galling and built-up edge formation, while the material’s inherent strength and work-hardening tendency demand substantial, stable cutting forces and rigid machine setups. Conventional machining parameters often result in poor surface integrity, dimensional inaccuracy, or premature tool failure, directly impacting part yield and cost-effectiveness.

At Shenzhen Honyo Prototype, we specialize in overcoming these complexities through dedicated CNC machining expertise honed over years of producing mission-critical titanium components. Our approach centers on optimized, application-specific processes. We utilize high-rigidity 5-axis CNC machining centers with precision spindles capable of maintaining exacting tolerances under heavy load. Crucially, we deploy specialized carbide tooling geometries and advanced coatings (such as AlTiN or nano-multilayer variants) designed explicitly for titanium’s abrasive nature and heat sensitivity. Our proven methodology emphasizes controlled, lower cutting speeds combined with aggressive but stable feed rates and depths of cut, maximizing metal removal while minimizing heat concentration. Integrated high-pressure through-spindle coolant delivery is non-negotiable in our process, ensuring effective chip evacuation and thermal management directly at the cutting interface. Rigorous fixturing strategies prevent workpiece deflection during machining, safeguarding geometric accuracy.

Our commitment to quality is embedded throughout production. Every titanium auto part undergoes stringent in-process inspection using coordinate measuring machines (CMMs) and surface profilometers to verify conformance to aerospace-derived standards. Post-machining treatments, including stress relief annealing where specified, ensure dimensional stability. The table below summarizes key capabilities relevant to automotive titanium part production:

| Parameter | Typical Industry Value | Honyo Prototype Standard |

| :—————– | :——————— | :———————– |

| Dimensional Tolerance | ±0.05 mm | ±0.01 mm (standard), ±0.005 mm (precision) |

| Surface Roughness (Ra) | 1.6 – 3.2 µm | ≤ 0.8 µm (standard), ≤ 0.4 µm (critical surfaces) |

| Common Part Types | Simple brackets | Complex suspension links, turbo manifolds, custom fasteners, brake components |

| Lead Time (Prototype) | 10-15 working days | 7-10 working days (typical) |

| Material Grades | Ti-6Al-4V (Grade 5) | Ti-6Al-4V, CP Titanium (Gr 1, 2), Beta alloys (on request) |

Honyo Prototype delivers more than just machined parts; we provide engineered solutions for the automotive sector’s most demanding titanium applications. Our deep process knowledge, investment in specialized tooling and metrology, and adherence to rigorous quality protocols ensure that every component meets the exacting performance, reliability, and safety standards required in modern high-performance and electric vehicles. Partner with us to transform the potential of titanium into realized automotive innovation.

Technical Capabilities

Technical Capabilities: Precision CNC Machining of Titanium Auto Parts

Shenzhen Honyo Prototype specializes in high-precision CNC machining of titanium components for performance and luxury automotive applications. Our advanced 3-axis, 4-axis, and 5-axis milling centers, combined with state-of-the-art CNC turning systems, enable us to produce complex titanium parts with exceptional accuracy, surface finish, and structural integrity. Titanium’s high strength-to-density ratio, corrosion resistance, and performance under extreme temperatures make it ideal for critical automotive systems such as suspension components, turbocharger housings, exhaust manifolds, and high-load fasteners. However, its low thermal conductivity and high chemical reactivity present unique machining challenges that demand specialized tooling, cooling strategies, and process control—capabilities fully integrated into our manufacturing workflow.

Our 5-axis simultaneous machining platforms allow for the production of highly intricate geometries in a single setup, minimizing part handling and ensuring superior dimensional consistency. This is particularly critical for titanium components where residual stresses and fixturing distortions can compromise final tolerances. With Y-axis travel up to 1,200 mm and high-torque spindle configurations (up to 8,000 rpm with through-coolant delivery), we maintain optimal cutting conditions for Ti-6Al-4V and other aerospace-grade titanium alloys commonly specified in high-performance automotive design.

Turning operations are performed on precision live-tooling lathes capable of sub-micron repeatability, supporting both bar-fed and chucking configurations for titanium shafts, fittings, and rotational components. Our in-house metrology suite—featuring coordinate measuring machines (CMM), laser scanners, and surface profilometers—ensures full traceability and compliance with AS9100 and ISO 9001 standards.

The following table outlines our standard and achievable machining tolerances and compatible titanium materials:

| Parameter | Specification |

|——————————-|—————|

| Machining Processes | 3-Axis Milling, 4-Axis Indexing Milling, 5-Axis Simultaneous Milling, CNC Turning (Swiss and Mill-Turn), Multi-Task Machining |

| Typical Titanium Alloys | Ti-6Al-4V (Grade 5), Ti-6Al-4V ELI (Grade 23), Ti-5Al-2.5Sn, Custom Titanium Blends |

| Standard Tolerance (Milling) | ±0.025 mm |

| Tight Tolerance (Milling) | ±0.005 mm (achievable on critical features with process validation) |

| Standard Tolerance (Turning)| ±0.015 mm |

| Tight Tolerance (Turning) | ±0.003 mm (on diametrical and axial features) |

| Surface Finish (Milling) | Ra 0.8 µm (standard), down to Ra 0.4 µm (polished or fine-cut) |

| Surface Finish (Turning) | Ra 0.4 µm (standard), down to Ra 0.2 µm |

| Max Work Envelope (5-Axis) | 1,200 mm × 800 mm × 750 mm |

| Min Feature Size (Milling) | 0.5 mm radius with micro-tooling support |

| Positional Accuracy | ±0.002 mm (with thermal compensation and laser calibration) |

All titanium machining operations are supported by optimized cutting parameters, cryogenic or high-pressure coolant delivery, and rigid toolholding systems to mitigate work hardening and tool wear. Shenzhen Honyo Prototype delivers titanium auto parts that meet the most demanding performance and fitment requirements in motorsport, electric vehicle, and high-end automotive sectors.

From CAD to Part: The Process

Titanium Automotive Component Manufacturing Workflow: From CAD to Finished Part

At Shenzhen Honyo Prototype, our CNC machining process for critical titanium automotive components follows a rigorously defined workflow to ensure precision, material integrity, and cost efficiency. This structured approach, moving seamlessly from initial design data to certified production part, is fundamental to meeting the demanding requirements of the automotive sector. The core sequence comprises AI-Powered Quoting, Comprehensive Design for Manufacturability (DFM) Analysis, and Precision Production Execution.

The process initiates with AI-Powered Quoting. Upon receiving the customer’s CAD model (typically STEP or IGES format), our proprietary AI engine rapidly analyzes geometric complexity, material volume, and feature density specific to titanium Grade 5 (Ti-6Al-4V), the predominant alloy in high-performance automotive applications. This system cross-references historical machining data, current machine tool availability, and real-time material costs to generate an accurate, data-driven quotation within hours. Crucially, it flags potential high-risk features early, such as deep cavities or thin walls prone to chatter in titanium, setting the stage for proactive DFM.

Comprehensive DFM Analysis is the critical engineering phase where manufacturability is optimized. Our senior engineers conduct a detailed review focusing on titanium’s unique challenges: low thermal conductivity, high chemical reactivity, and tendency for work hardening. We evaluate tool accessibility, recommend optimal stock allowances to minimize material removal while ensuring structural integrity, and suggest geometric modifications where necessary – such as increasing corner radii to reduce tool stress or adjusting draft angles for fixture stability. Material grain flow orientation relative to high-stress features is assessed. This collaborative step, involving direct consultation with the client, resolves conflicts between design intent and titanium’s machining realities, significantly reducing lead times and preventing costly iterations during production.

Precision Production Execution leverages Honyo Prototype’s advanced CNC capabilities under strict environmental controls. Titanium machining demands specialized parameters and tooling to manage heat generation and prevent galling. Parts are fixtured using custom, low-reactivity clamping solutions to avoid surface contamination and distortion. Machining occurs under high-pressure coolant systems (typically 1000+ PSI) using sharp, coated carbide tools with aggressive positive geometries. Processes follow a strict sequence: roughing with controlled depths of cut to manage heat, semi-finishing for dimensional stability, and high-precision finishing passes. In-process inspections verify critical dimensions after key operations. The table below outlines essential titanium machining parameters employed:

| Parameter | Typical Range for Ti-6Al-4V | Critical Consideration |

| :—————– | :————————– | :—————————————– |

| Cutting Speed (Vc) | 30 – 60 m/min | Lower speeds essential to manage heat |

| Feed per Tooth (fz)| 0.05 – 0.15 mm/tooth | Must balance chip evacuation & tool life |

| Coolant Pressure | 1000 – 2000 PSI | Critical for chip flushing & cooling |

| Tool Coating | AlTiN, AlCrN | Reduces adhesion & heat transfer to tool |

| Spindle RPM | Adjusted per tool diameter | Maintains optimal surface speed (Vc) |

Final quality assurance includes full CMM inspection against the original CAD model, surface roughness verification (Ra ≤ 0.8 µm typical for critical surfaces), and material traceability documentation per IATF 16949 standards. This integrated workflow, from AI-driven quoting through titanium-specific DFM to controlled production, ensures Honyo Prototype delivers automotive titanium components that meet the exacting performance, reliability, and safety demands of modern vehicle systems.

Start Your Project

Start Your Titanium Auto Parts Project with Precision Engineering from Shenzhen Honyo Prototype

When it comes to high-performance automotive applications, titanium stands out for its exceptional strength-to-density ratio, corrosion resistance, and ability to withstand extreme temperatures. At Shenzhen Honyo Prototype, we specialize in CNC machining of titanium auto parts with tight tolerances, complex geometries, and repeatable accuracy. Whether you’re developing prototype components for motorsports, high-end performance vehicles, or next-generation electric powertrains, our manufacturing expertise ensures your design transitions seamlessly from concept to production-ready part.

Our CNC machining capabilities are optimized for titanium alloys such as Ti-6Al-4V (Grade 5), Ti-6Al-7Nb, and commercially pure grades, all commonly used in automotive turbo manifolds, exhaust systems, suspension components, and fasteners. Utilizing state-of-the-art 3-, 4-, and 5-axis CNC centers, we deliver precision-machined parts with superior surface finishes and structural integrity. Our in-house engineering team collaborates closely with clients to review designs for manufacturability, recommend material selections, and optimize toolpaths to reduce cycle times and costs—without compromising quality.

We understand that every automotive project has unique demands. That’s why we offer scalable production runs—from single prototype units to low-volume batch manufacturing—backed by rigorous quality control. All titanium components undergo dimensional inspection using CMM (Coordinate Measuring Machine), surface roughness testing, and material verification to ensure compliance with industry standards.

Below are our key technical capabilities for titanium CNC machining:

| Specification | Detail |

|————–|——–|

| Material Compatibility | Ti-6Al-4V (Grade 5), Ti-6Al-7Nb, CP Titanium (Grades 1–4) |

| Tolerance | ±0.005 mm (±0.0002″) |

| Surface Finish | As low as Ra 0.8 μm (32 μin), customizable |

| Maximum Part Size | 800 × 500 × 400 mm |

| Machining Types | 3-axis, 4-axis, 5-axis CNC milling, turning |

| Lead Time | 7–15 days (depending on complexity and quantity) |

| Quality Standards | ISO 9001:2015 compliant, full inspection reports available |

At Shenzhen Honyo Prototype, we are committed to accelerating your product development timeline with responsive service, technical transparency, and precision manufacturing. Our team is ready to support your next titanium auto part project from initial design review to final delivery.

Contact Susan Leo today to start your project.

Email: info@hy-proto.com

Let us help you turn high-performance ideas into engineered reality.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.