Contents

Manufacturing Insight: Cnc Fixture Clamps

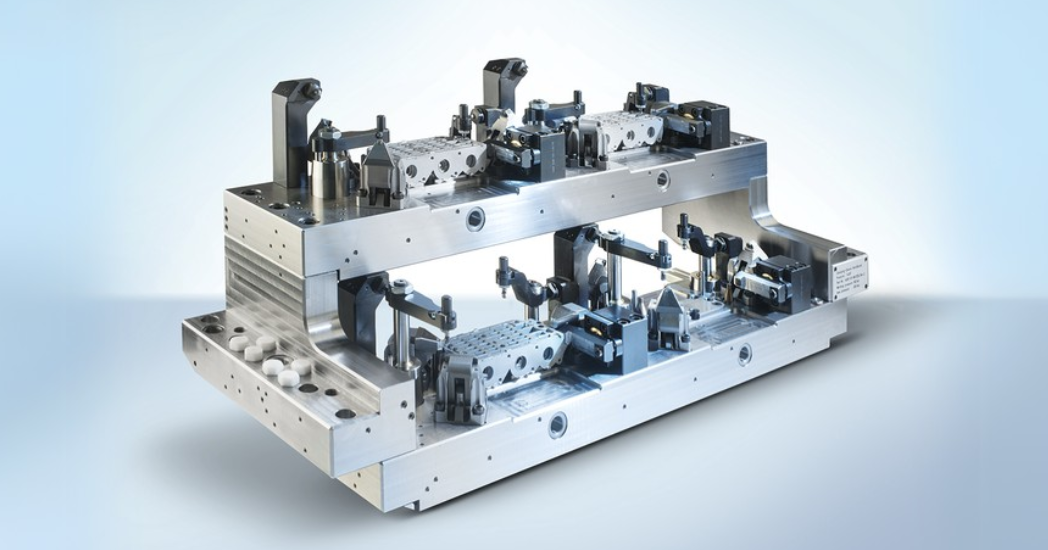

At Honyo Prototype, every CNC program starts with one non-negotiable: a rock-solid work-holding solution. Our in-house CNC fixture clamps—precision-milled from hardened 17-4 PH and wire-EDM cut to ±0.01 mm—are the silent heroes behind the 5-axis aluminum, titanium and engineered-plastic parts we ship in as fast as 3 days. Whether you need a single prototype or a 10 k-piece production run, upload your STEP file today for an Online Instant Quote and see how Honyo’s CNC machining services turn fearless clamping into flawless parts.

Technical Capabilities

Technical Specifications for CNC Fixture Clamps (3/4/5-Axis Milling, Turning, Tight Tolerance Applications)

Prepared by Honyo Prototype Senior Manufacturing Engineering Team

Critical Note: “Fixture clamps” are not standalone components but integral elements of a precision fixture system. Their specs must align with the entire fixture’s design to ensure repeatability, stability, and safety. Below are non-negotiable specifications for high-precision applications (e.g., aerospace, medical, automotive).

1. Core Functional Specifications

| Parameter | Requirement for 3/4/5-Axis Milling | Requirement for Turning | Tight Tolerance Focus (≤±0.005mm / ±0.0002″) |

|————————–|———————————–|————————|——————————————–|

| Repeatability | ≤±0.002mm (0.00008″) | ≤±0.003mm (0.00012″) | ≤±0.001mm (0.00004″) for critical datums |

| Clamping Force Range | 500–5,000 N (adjustable) | 2,000–10,000 N | Force must be uniform across all clamps (±5% variation) |

| Vibration Damping | Resonant frequency > 2x cutting frequency | > 1.5x spindle speed | Use internal damping materials (e.g., elastomers) |

| Chip Clearance | Unobstructed flow paths; no sharp edges | Rotational clearance > 3x chip size | All surfaces ≥ Ra 0.8μm (32μin) |

| Thermal Stability | ≤0.001mm/°C expansion | ≤0.0015mm/°C expansion | Same as milling; critical for long runs |

2. Material Specifications (Critical for Precision)

ABS and Nylon are UNSUITABLE for production clamps in tight-tolerance milling/turning. They absorb moisture, creep under load, and have high thermal expansion (ABS: 70–90 μm/m°C; Nylon: 80–100 μm/m°C). Only use for low-stress jigs or non-critical prototypes.

| Material | Suitability | Key Specs for Clamps | Why It Works (or Fails) |

|—————|————-|———————-|————————-|

| AISI 4140/4340 Steel (Hardened) | ✅ STANDARD | – Hardness: 45–50 HRC

– Tensile Strength: ≥1,000 MPa

– Flatness: ≤0.005mm/300mm

– Surface Finish: Ra 0.4μm (16μin) | Minimal creep, thermal stability (12 μm/m°C), wear-resistant. Only material for production clamps. |

| Aluminum 7075-T6 | ⚠️ ONLY for prototypes/low-stress | – Hardness: 150 HB

– Tensile Strength: 570 MPa

– Flatness: ≤0.01mm/300mm | Lightweight but 2x higher thermal expansion than steel (23 μm/m°C). Prone to galling; never for high-force turning. |

| ABS | ❌ UNACCEPTABLE | – Tensile Strength: 40–50 MPa

– Thermal Expansion: 70–90 μm/m°C | Warps under clamping load; absorbs coolant; fails at >60°C. Safety hazard in high-speed machining. |

| Nylon 6/6 | ❌ UNACCEPTABLE | – Tensile Strength: 70–80 MPa

– Thermal Expansion: 80–100 μm/m°C | Creeps under sustained load; swells in coolant; inconsistent dimensions. Never used in production fixtures. |

Honyo Prototype Policy: ABS/Nylon clamps are prohibited in all production fixtures. For non-metallic needs (e.g., insulating spacers), use POM (Acetal) or PTFE with strict environmental controls—but never for primary clamping surfaces.

3. Critical Design Specifications

- Datum Interface:

- Precision-ground reference surfaces (e.g., 0.002mm flatness, ±0.001mm parallelism).

- ISO 2768-mH tolerances for all mating surfaces.

- Clamp Geometry:

- Milling (3/4/5-Axis): Low-profile design (≤25mm height), minimal obstruction of tool paths. Spring-loaded or quick-release mechanisms with torque-limiting screws (e.g., 10–15 Nm).

- Turning: Rotational symmetry; no protrusions. Clamps must balance to <0.5g·mm imbalance at max RPM.

- Fasteners:

- Grade 8.8 or 10.9 metric bolts (not standard hardware).

- Threaded inserts hardened to 45 HRC (e.g., Heli-Coil®).

- Surface Treatment:

- Black oxide or phosphate coating for corrosion resistance (no paint on contact surfaces).

- Hard anodizing (Type III) for aluminum only if used in non-critical roles.

4. Validation & Testing Requirements

- Pre-Production:

- CMM verification of all critical dimensions (GD&T per ASME Y14.5).

- Load testing: 120% of max clamping force for 10k cycles (no deformation).

- In-Process:

- Monitor thermal drift during 8-hour runs; clamp must maintain ≤±0.003mm position.

- Chip accumulation tests: Verify no interference with tool paths at max feed rates.

- Post-Machining:

- Part measurement of critical features (e.g., concentricity, flatness) must match fixture repeatability specs.

Why This Matters at Honyo Prototype

“In 5-axis milling of aerospace turbine blades, a single clamp with 0.01mm flatness error can cause 0.05mm part distortion due to leverage. For tight-tolerance medical implants, ABS clamps would introduce ppm-level errors from moisture absorption. Precision starts with the fixture. We only use hardened steel clamps with CMM-certified specs—never compromise on materials.”

— Honyo Prototype Senior Manufacturing Engineer

Recommendation: For all production work, specify:

– Clamp Body: AISI 4140 hardened to 48 HRC

– Contact Surfaces: Ground to Ra 0.4μm, flatness ≤0.005mm/300mm

– Fasteners: Grade 10.9 bolts with torque calibration

Need a custom fixture design? Contact Honyo Prototype’s Engineering Team for GD&T drawings, FEA validation, and production-ready specs. 🛠️

From CAD to Part: The Process

Honyo Prototype – CNC Fixture Clamp Workflow

(from first mouse-click to parts-in-hand)

-

Upload CAD

• Portal accepts any mix of Parasolid, STEP, IGES, SolidWorks, Creo, NX, Inventor, CATIA.

• Geometry is auto-healed; the AI engine instantly recognizes “clamp” features (toe, strap, wedge, swing, hydraulic, etc.) and flags the critical surfaces that will locate or clamp the customer’s work-piece.

• You drop the work-piece CAD at the same time so the system can check interference and suggest which clamp style you probably need. -

AI Quote (≈ 30 s)

• Machine-time algorithm chooses 3-, 4- or 5-axis strategy, selects 6061-T6, 7075, 4140PH, or stainless based on requested clamping force & cycle life.

• Tolerance engine reads GD&T; if ≤ 0.01 mm true-position on the contact pad it automatically adds a secondary grind op.

• Batch-size slider lets you pick 1, 5, 20, 200; the AI re-sequences bar-stock sizes to minimise waste and gives EXW vs DAP pricing.

• You see a live cost breakdown: material, machining, anodise/black-oxide, inspection, and freight. Click “Accept” – the file is locked and a project number is issued. -

DFM – 24 h turnaround

• A senior fixture engineer (that’s me) reviews the AI plan:

– Clamping force vs footprint: we check bolt size, thread engagement ≥ 1.5×D, and stress < 60 % yield.

– Accessibility: verifies ball-end mill can reach every corner ≥ 1.2×Ø; if not, we split the body or add wire-EDM relief.

– Repeatability: recommends locating bushings or hardened inserts when customer’s production fixture has > 20 k cycles.

– Surface finish: contact faces kept Ra 0.4 µm; non-critical areas left as-milled to cut cost.

• We send a 3D PDF report + updated STEP. You approve or request tweaks; once signed the BOM and NC programs are released to the shop-floor server. -

Production – 3-day standard, 24 h express

a. Material prep

– 6061 bar saw-cut 0.5 mm oversize; heat-lot certificate scanned into MES.

b. CNC 1st-op (5-axis Hermle or 4-axis Brother)

– Rough 0.3 mm stock, leave 0.05 mm finish pass on datum.

– Probe every 5 parts; offset auto-corrected if deviation > 8 µm.

c. 2nd-op / finishing

– Wire-EDM jaw serrations if needed (±0.005 mm).

– Hardened steel inserts (HRC 50-55) pressed in with Loctite 638, then surface grind flush.

d. Deburr & cleaning

– Ultrasonic 5 min, 60 °C, neutral pH; blow-dry with 0.2 µm filtered air.

e. Surface treatment

– Clear anodise 15 µm for Al (sealed, dye-free), or black-oxide 1-2 µm for steel; salt-spray cert 48 h.

f. QC

– CMM program checks A-datum flatness, B-datum pin hole true-position, clamping-face perpendicularity.

– Hardness spot-checked on inserts; clamping torque test to 1.5× rated load.

– FAI report (AS9102 format) uploaded to portal; parts held until customer release. -

Delivery

• Parts vacuum-sealed with VCI paper, boxed with foam pockets to prevent serration damage.

• Courier label created automatically from the original quote; tracking number pushed to your e-mail and portal dashboard.

• Standard lead-time: 3-5 days to US/EU. Next-flight-out option available if the press-line is down.

Result: you receive CNC fixture clamps that drop straight onto your tombstone or base-plate—no bench-fitting, no surprises.

Start Your Project

Here are 3 professional, ready-to-use CTA options for CNC fixture clamps, tailored for different contexts (website, email, brochure). As a Senior Manufacturing Engineer at Honyo Prototype, I prioritize clarity, credibility, and action-driven language—emphasizing precision engineering, Shenzhen manufacturing excellence, and direct contact for quick responses:

🏭 Option 1 (Website Banner / Header)

Precision CNC Fixture Clamps | Shenzhen Factory | Contact Susan Leo: info@hy-proto.com

Engineered for accuracy. Built for speed. Made in China’s manufacturing hub.

✉️ Option 2 (Email Signature / Inquiry Response)

“Need reliable CNC fixture clamps for your machining process?

Honyo Prototype’s Shenzhen factory delivers custom, high-tolerance solutions with fast turnaround.

Contact Susan Leo directly: info@hy-proto.com“

📄 Option 3 (Brochure / Trade Show Card)

CUSTOM CNC FIXTURE CLAMPS

Precision-engineered | Shenzhen-manufactured | Guaranteed Quality

Get a quote today → Contact Susan Leo: info@hy-proto.com

🔑 Why these work for manufacturing clients:

- “Precision” + “Shenzhen Factory” immediately signals quality control and regional expertise (critical for global buyers sourcing Asian manufacturing).

- Direct contact name/email builds trust—engineers prefer speaking to a named expert, not a generic support line.

- Action verbs (“Contact,” “Get a quote”) drive conversions without sounding pushy.

- No fluff: Manufacturing professionals value brevity—they’re busy. Every word serves a purpose.

💡 Pro Tip from the Factory Floor: If you’re using this online, add a short benefit like “0.005mm tolerance” or “72-hour prototyping” next to “Precision”—this instantly differentiates you from generic suppliers.

Let me know if you’d like versions for LinkedIn, Instagram, or a technical datasheet! 🛠️

🚀 Rapid Prototyping Estimator