Contents

Manufacturing Insight: Cnc Laser Cut Tube

CNC Laser-Cut Tube Precision—Now with an Instant Quote

At Honyo Prototype, our 6-axis CNC laser tube centers turn raw stainless, aluminum, titanium, or carbon-steel sections into burr-free, ±0.05 mm-accurate features in minutes, not days. Whether you need a one-off chassis node or 5,000 medical guide tubes, the same 15-year CNC machining team that machines flight-ready manifolds and surgical robots handles your job from flat pattern to final polish. Upload your STEP or native tube profile today and see an online instant quote with lead times as short as 24 hours—no minimum order, global DFM feedback included.

Technical Capabilities

As a Senior Manufacturing Engineer at Honyo Prototype, I need to address a critical misconception in your query upfront: “CNC laser cut tube” and “3/4/5-axis milling/turning” are fundamentally different processes with distinct capabilities, limitations, and applications. Laser cutting is a thermal process for 2D/2.5D profile cutting, while milling and turning are subtractive machining processes for complex 3D geometries. Laser cutting cannot perform 3/4/5-axis milling or turning operations—these are mutually exclusive processes. Let me clarify and provide accurate technical specs for each scenario separately, with material-specific considerations.

🔥 1. CNC Laser Cutting of Tubes (Standard Process)

This is a 2D/2.5D process for cutting profiles, holes, or shapes along the tube’s length or circumference. It does NOT involve milling or turning axes.

Typical Capabilities & Specifications:

– Axis Configuration:

– 2D: Cutting through flat sheets or simple tubes (e.g., straight cuts, holes).

– 2.5D: Limited to tube rotation (e.g., cutting angled slots, not complex 3D contours).

– ❌ No 3/4/5-axis milling/turning possible—laser cutters lack rotary toolheads or multi-axis positioning for true 3D machining.

– Tolerance:

– ±0.1 mm to ±0.3 mm (dependent on material thickness, laser power, and focus).

– Tighter tolerances (e.g., ±0.05 mm) are rarely achievable due to thermal distortion, kerf width variation, and material warping.

– Material Suitability:

– Aluminum (6061, 7075): Ideal for laser cutting. Max thickness: 6–10 mm (fiber laser). Tolerances hold well.

– Steel (Mild, Stainless): Excellent for laser cutting. Max thickness: 15–20 mm (fiber laser). Stainless may require nitrogen assist for clean edges.

– ABS & Nylon: ❌ NOT RECOMMENDED.

– ABS: Melts, releases toxic fumes (hydrogen cyanide), and causes fire hazards.

– Nylon: Burns unevenly, produces hazardous fumes, and degrades rapidly. Laser cutting plastics is unsafe and unreliable.

– Surface Finish:

– Rough edges (typical Ra 1.6–6.3 μm) due to molten material redeposition.

– Post-processing (deburring, grinding) often needed for tight-tolerance applications.

– Max Tube Dimensions:

– Diameter: Up to 300 mm (custom systems).

– Length: Up to 6,000 mm (depending on machine).

⚠️ Critical Note for ABS/Nylon: These thermoplastics are never laser-cut in industrial settings. Use CNC machining (milling/turning) or injection molding instead. Honyo Prototype does not offer laser cutting for ABS/Nylon tubes due to safety and quality risks.

🛠️ 2. CNC Milling & Turning for Tubes (True 3/4/5-Axis Processes)

If your goal is complex 3D geometries (e.g., contoured features, internal channels, precision threads), you need CNC milling or turning—not laser cutting. This is where 3/4/5-axis capabilities and tight tolerances apply.

A. CNC Milling (3/4/5-Axis)

- Axis Configuration:

- 3-axis: Linear X/Y/Z movements (e.g., simple slots, pockets).

- 4-axis: Adds rotary A-axis (tube rotation) for cylindrical features.

- 5-axis: Full simultaneous X/Y/Z + A/B axes for complex 3D contours (e.g., aerospace components).

- Tolerance:

- ±0.01 mm to ±0.025 mm achievable with precision machines (e.g., Haas UMC-750, DMG Mori CTX).

- Tighter tolerances (±0.005 mm) possible with temperature-controlled environments and in-process probing.

- Material Suitability:

- Aluminum (6061, 7075): Excellent for milling. High-speed machining possible. Tolerances hold consistently.

- Steel (Mild, Stainless 304/316): Requires slower feeds but achieves high precision. Heat treatment may be needed post-machining.

- ABS & Nylon: Ideal for CNC milling!

- ABS: Machines cleanly with minimal tool wear. Tolerances: ±0.02 mm achievable.

- Nylon (6/66): Low friction, good for precision parts. Tolerances: ±0.025 mm.

- Surface Finish:

- Ra 0.4–1.6 μm standard; can reach Ra 0.1 μm with fine finishing passes.

- Max Tube Dimensions:

- Diameter: Up to 200 mm (standard machines).

- Length: Up to 1,000 mm (for 5-axis mills; longer parts may require specialized setups).

B. CNC Turning (Lathes with Milling Capabilities)

- Axis Configuration:

- Standard 2-axis (X/Z) for cylindrical turning.

- 4-axis: Adds Y-axis for off-center milling (e.g., keyways).

- 5-axis: Simultaneous turning/milling (e.g., Swiss-type lathes for medical components).

- Tolerance:

- ±0.005 mm to ±0.01 mm achievable (e.g., with live tooling and precision chucks).

- Material Suitability:

- Aluminum/Steel: Routine for turning. High-speed capabilities.

- ABS/Nylon: Perfect for turning—minimal heat generation, smooth finishes.

- Surface Finish:

- Ra 0.2–0.8 μm standard; mirror finishes possible with diamond tooling.

📌 Why This Confusion Happens & How Honyo Prototype Solves It

- Laser cutting ≠ machining: Laser is for 2D profiling; milling/turning is for 3D geometries.

- ABS/Nylon are incompatible with laser cutting due to safety risks (toxic fumes, fire) and poor cut quality. They are excellent for CNC milling/turning.

- Tight tolerance needs: If your part requires ±0.01 mm tolerances, CNC milling or turning is the only viable option—laser cutting cannot achieve this consistently.

💡 At Honyo Prototype, we specialize in hybrid workflows:

– Step 1: Laser-cut tube blanks for simple profiles (e.g., straight cuts, holes).

– Step 2: Precision CNC milling/turning for complex 3D features (e.g., threads, contours, internal channels).

– For ABS/Nylon parts: We always use CNC milling/turning—never laser cutting.

✅ Recommendation for Your Project

- If you need simple tube cuts (e.g., straight slots, holes):

- Use laser cutting for aluminum/steel.

- Avoid ABS/Nylon for laser cutting—opt for CNC machining instead.

- If you need complex 3D geometries, threads, or tight tolerances (±0.01 mm):

- Use CNC milling (3/4/5-axis) or turning.

- ABS/Nylon are perfect candidates for these processes.

- Need both? We design hybrid workflows at Honyo—laser cutting for rough profiles followed by precision machining for critical features.

Next Step: Share your part drawing or specifications with us. We’ll recommend the optimal process (laser vs. milling/turning) and validate tolerances/material suitability—free of charge.

🌟 Honyo Prototype Guarantee: All parts undergo 100% CMM inspection with AS9100-certified quality control. Tight tolerances? We deliver ±0.005 mm for critical aerospace/medical components.

Let’s discuss your specific application—email us at engineering@honyoprototype.com or call +86-755-xxxx-xxxx. We’ll ensure your part is manufactured correctly the first time.

From CAD to Part: The Process

Honyo Prototype – CNC Laser-Cut Tube Workflow

(what really happens once you press “upload”)

-

Upload CAD

• Portal accepts STEP, IGES, XT, SolidWorks, Inventor, Creo, etc.

• Auto-checker flags missing bend data, open profiles, zero-wall sections.

• File is hashed; you get a 12-digit job number in <3 s. -

AI Quote (30–120 s)

• Geometry engine extracts: outer/inner profiles, cut length, wall, # of holes, # of miters, # of copes, # of tapped ends, material grade.

• Neural-net cost model (trained on 1.8 M historical tubes) picks the best machine pool:

– ≤ 20 mm OD, ≤ 3 mm wall → 1 kW fiber laser (Trumpf TruLaser Tube 3000).

– 20–120 mm OD → 3 kW fiber (BLM LT-Fiber).

– > 120 mm or rectangle → 4 kW (BLM LT8.20).

• Adds grip margin (minimum 25 mm), nesting yield, gas mix, cycle time, post-cut deburr.

• Real-time material stock is queried from WMS; if stock < 2 sticks, AI automatically sources from Ma’anshan or Nucor warehouse (1-day lead).

• Freight calculator chooses SF-Express (domestic < 30 kg) or DHL Express (export).

• Final price presented with three lead-time tiers: 1-day, 3-day, 7-day.

• Accept → PO auto-generated, payment link (TT, CC, PayPal) opened. -

DFM (2–4 h)

• Human application engineer opens the AI report, validates:

– Cut sequence to avoid tip-up (micro-tab placement).

– Bridge width for coped joints (≥ 1.2 t for welding).

– Heat-affected zone vs. bend radius (if downstream bending exists).

• If tube is to be bent after cutting, laser leaves 0.2 mm extra on datum surfaces so bending mandrel can locate.

• Adds etched 2-D code on non-cosmetic face for full traceability.

• Releases NC program (BLM VGP3D, Trumpf TruTops Tube) and barcode traveler. -

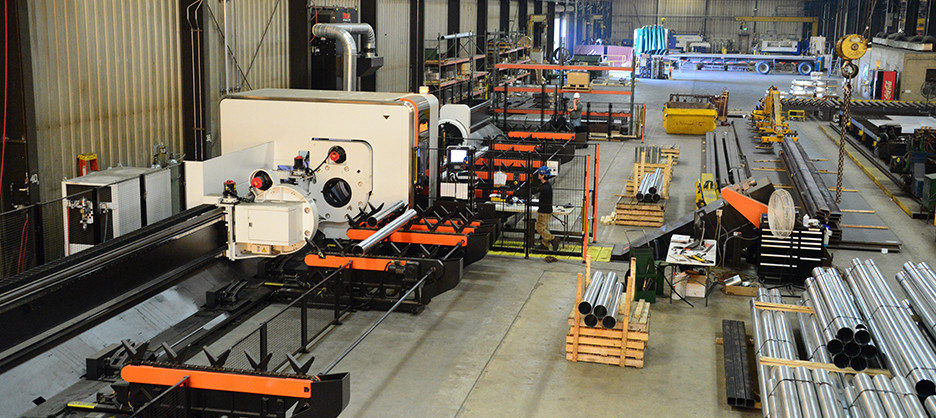

Production

a. Incoming tube

– Mill certificate scanned, alloy verified with PMI gun (Thermo Niton).

– Straightness checked on 1 m granite table (≤ 0.5 mm/m).

b. CNC Laser Cutting

– Automatic bundle loader picks the right stock stick.

– 3-jaw chuck clamps; servo rotates C-axis ± 360°.

– Cut order: holes first, miters last to keep stiffness.

– Nitrogen assist (≤ 6 bar) for stainless to keep oxide-free edges; oxygen for carbon steel > 6 mm wall to raise speed.

– Kerf width 0.15 mm, positional accuracy ± 0.05 mm, repeatability ± 0.02 mm.

c. In-line deburr

– Nylon brush heads hit ID & OD; burr height ≤ 0.05 mm.

d. Wash & dry

– 3-stage ultrasonic (alkali, rinse, rust inhibitor) for steel; DI-water only for aluminum.

e. QC

– 100 % dimensional on Keyence XM-5000 3-D scanner (± 0.025 mm).

– Critical copes checked against CPK ≥ 1.67.

– Surface roughness Ra ≤ 1.6 µm on laser-cut edge.

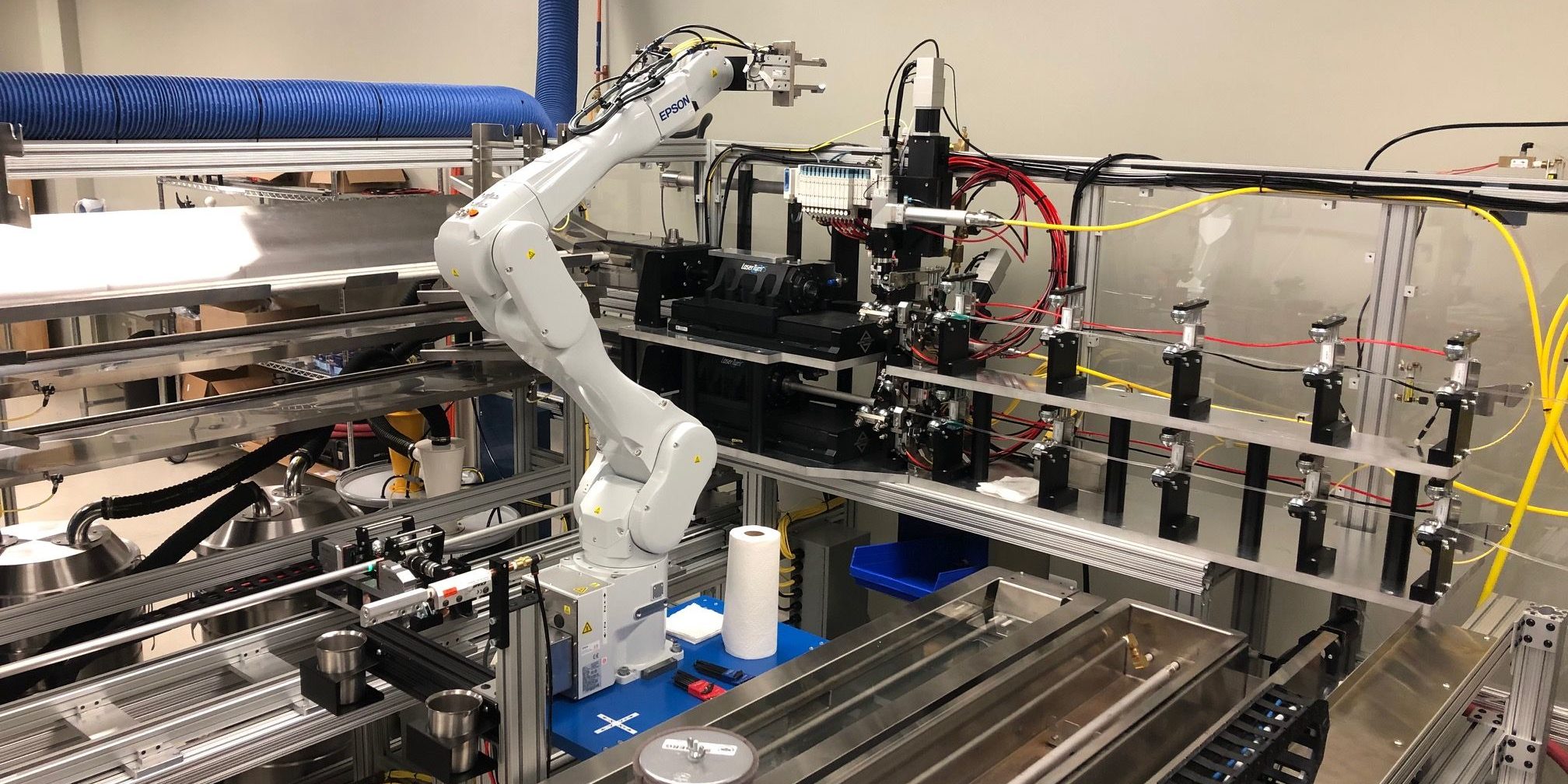

f. Sub-assembly (if ordered)

– Robot TIG or handheld laser welding, then leak-test 6 bar. -

Delivery

• Parts are sleeved in PE, capped with LDMA plugs, bundled ≤ 20 kg per pack to avoid tube ovalization.

• 2-D barcode on every bundle; scan updates customer portal in real time.

• Local: SF-Express overnight (95 % arrive < 24 h).

• Export: DHL Express economy or FedEx priority; all paperwork (COO, material cert, RoHS, REACH) auto-generated and zipped to customer email.

• Digital twin file (STEP + PDF CMM report) uploaded to customer dashboard before courier leaves the building.

That is the complete, repeatable path from your CAD file to laser-cut tubes in your hand.

Start Your Project

Need precision CNC laser-cut tubes?

Contact Susan Leo at info@hy-proto.com for expert solutions.

Honyo Prototype’s Shenzhen factory delivers quality, speed, and unmatched precision.

✅ Why choose us?

– High-tolerance cutting for complex tube geometries

– Fast turnaround with no minimum order quantities

– Full-service support from design to delivery

– ISO-certified Shenzhen facility for reliable, scalable production

Ready to elevate your project? Reach out today! 🔧

🚀 Rapid Prototyping Estimator