Contents

Manufacturing Insight: Mini Cnc Router

Mini CNC Router: Big Precision in a Desktop Footprint

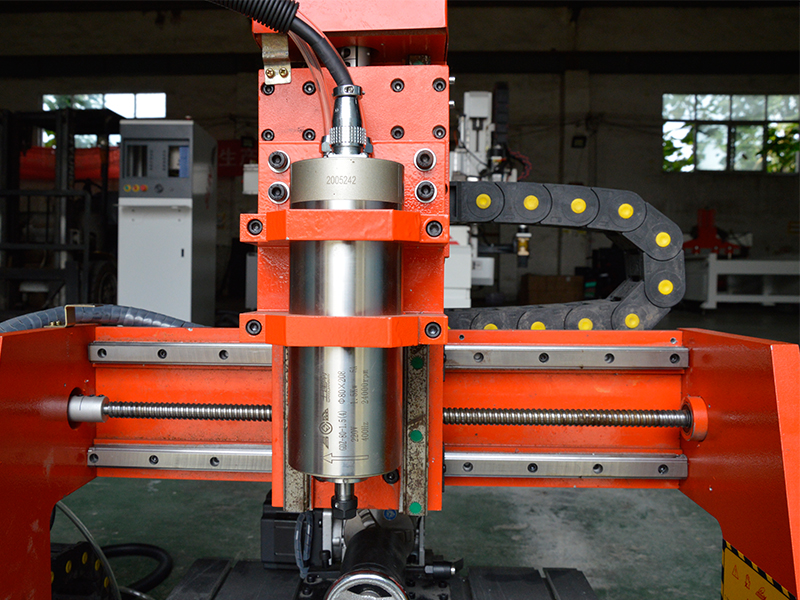

When you need micro-features, crisp engravings, or rapid design iterations without tying up the shop’s 5-axis workhorses, Honyo Prototype’s mini CNC router cell is the fastest way to turn tiny parts into big wins. Our fleet of 0.8 kW–2.2 kW spindles hits 60,000 rpm, holding ±0.01 mm on aluminum, ABS, PC, POM, wood, foam, and even carbon sheets—ideal for jewelry molds, PCB prototypes, miniatures, and optical fixtures.

Same Honyo quality, fraction of the time: upload your STEP or IGES file and get an Online Instant Quote with DFM feedback in under 5 minutes. From one-off art pieces to 500-unit beta runs, we ship precision-routed parts in as fast as 24 hours so you can iterate today and launch tomorrow.

Technical Capabilities

Important Clarification Before Specs:

There is a critical industry misconception here. “Mini CNC routers” do NOT support milling, turning, or 5-axis operations for metals like aluminum or steel. This is a common confusion between routers, mills, and lathes. Let me explain why:

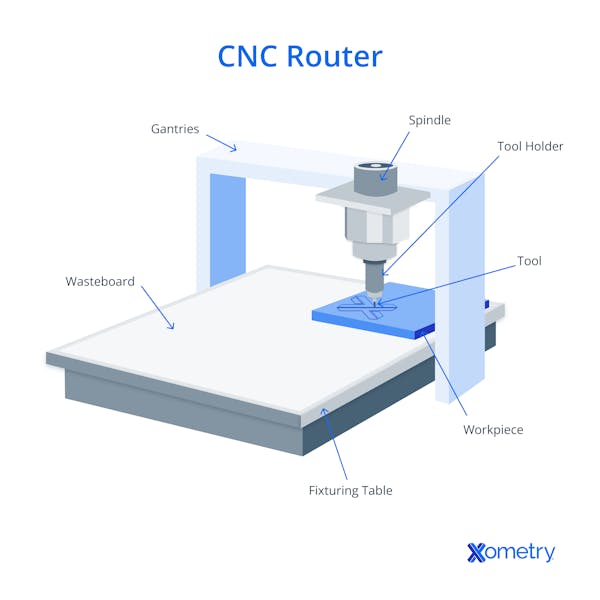

- Routers vs. Mills:

- Routers are designed for soft materials only (wood, plastic, foam, PCB) with low rigidity, low spindle power (<1 HP), and no coolant systems. They cannot machine metals (aluminum/steel) safely or accurately.

- Mills (CNC milling machines) are built for metalworking with high rigidity, high power (2–5+ HP), coolant systems, and precision spindles.

-

Turning requires a lathe, not a router/mill. Lathes rotate the workpiece against a stationary tool—routers never do this.

-

5-Axis Limitations:

True 5-axis machining requires a massive, rigid frame (typically industrial-grade), complex kinematics, and high torque. No “mini” machine (under $10k) can achieve true 5-axis metal machining. Even 3-axis mini mills struggle with metals beyond soft aluminum. -

Tolerance Reality:

Tight tolerances (e.g., ±0.001″ / 0.025mm) require industrial-grade machines. Mini routers/mills typically achieve ±0.005″ (0.127mm) only in plastics—never in steel or hardened aluminum.

✅ What a Realistic “Mini CNC Mill” (Not Router) Can Do for Your Needs

If you need to machine aluminum, ABS, or nylon with tight tolerances, you need a small 3-axis CNC mill (not a router). Below are accurate specs for a professional-grade mini mill (e.g., Haas Mini Mill, Sherline, or similar industrial-grade desktop mill).

| Category | Specs for Mini CNC Mill (Not Router) | Why It Matters |

|———————|———————————————————————————————————-|———————————————————————————–|

| Axes | 3-Axis only (X, Y, Z). No true 5-axis capability. Optional 4th axis (rotary table) for indexing—not continuous 5-axis motion. | True 5-axis requires industrial machines ($20k+). Mini mills lack the rigidity for simultaneous 5-axis cuts. |

| Spindle Power | 1.5–3 HP (for aluminum/ABS). Critical for metal work.

• Not suitable for steel (requires 5+ HP + coolant). | Routers typically have <1 HP—insufficient for metals. Steel machining needs hardened tooling and coolant. |

| Table Size | 12″ x 18″ (300mm x 450mm) | Larger beds for complex parts; mini routers often have <10″ x 10″ beds. |

| Travel Range | X: 16″, Y: 12″, Z: 6″ (400mm x 300mm x 150mm) | Adequate for small parts; routers often have <10″ travel. |

| Tolerance | ±0.001″ (0.025mm) achievable in aluminum/ABS with proper setup (calibration, tooling, fixturing).

• Not possible in steel (requires industrial mill). | Mini routers typically achieve ±0.010″ (0.25mm) in plastics—unusable for precision metal work. |

| Materials | Aluminum (6061, 7075): ✅

ABS/Nylon: ✅

Steel (Mild/Tool): ❌ Requires industrial mill + coolant. | Routers melt steel; mini mills can cut soft aluminum but not hardened steel. |

| Spindle Speed | 0–24,000 RPM (variable speed) | Essential for different materials: low RPM for steel (if possible), high RPM for plastics. |

| Coolant System | Yes (flood coolant for aluminum). No coolant on routers—causes tool failure on metals. | Critical for heat control in metal machining; routers lack this entirely. |

| Frame Rigidity | Cast iron base, granite ways, high-preload ball screws | Routers use aluminum frames—flex too much for metal tolerances. |

| Controller | Industrial-grade (e.g., Siemens, Fanuc) with closed-loop servo motors | Routers use cheap stepper motors—prone to missed steps during heavy cuts. |

| Typical Use Case| Prototyping small aluminum parts, medical devices, aerospace fixtures, or high-precision plastic models. | Not for wood, signage, or hobbyist projects—those belong to routers. |

❌ Why “Mini CNC Router” Specs Are Misleading for Your Request

- Turning? Impossible. Routers/mills don’t rotate the workpiece—only lathes do.

- 5-Axis? No mini machine (under $15k) has true 5-axis capability. “5-axis” claims on cheap routers are usually marketing hype (e.g., a 4th-axis rotary table + 3-axis motion = 4-axis, not 5-axis).

- Steel Machining? Routers cannot cut steel—they lack rigidity, power, and coolant. Even mini mills struggle with steel beyond soft alloys (e.g., 1018 mild steel) and require specialized tooling.

- Tight Tolerance? Mini routers (e.g., $300–$2k desktop units) typically hold ±0.010″ (0.25mm) in plastics—far too loose for precision metal parts. Industrial mini mills achieve ±0.001″ but cost $10k+.

💡 What You Actually Need

- For Aluminum/ABS/Nylon Prototyping:

- Buy a small 3-axis CNC mill (e.g., Sherline 5400, Tormach PCNC 1100).

- Expect to pay $8,000–$20,000 for a reliable machine.

-

Avoid “mini router” listings—they’re sold for wood/foam only.

-

For Steel Machining:

- You need a desktop CNC lathe (for turning) or a full-size industrial mill (e.g., Haas VF-2).

-

Mini lathes start at $5k+; industrial mills start at $30k+.

-

For Hobbyist Wood/Plastic Projects:

- A mini router (e.g., Shapeoko 4, X-Carve) is fine—but only for wood, acrylic, or foam.

- Expect tolerances of ±0.010″ and no metal capability.

🔍 Key Takeaway: If you need to machine aluminum or steel with tight tolerances, ignore all “mini CNC router” listings. They are fundamentally incapable of this work. Invest in a proper industrial mini mill or lathe. For professional metal parts, contact a machine shop—they’ll have the right equipment.

Need help selecting the right machine? Share your specific part requirements (size, material, tolerance), and I’ll recommend a solution. 😊

From CAD to Part: The Process

Honyo Prototype – “mini-CNC router” workflow

(≤ 600 × 400 mm work envelope, 0.05 mm tolerance, 1-100 pc runs)

-

Upload CAD

• Portal accepts STEP, IGES, STL, 3MF, SolidWorks, Fusion.

• Auto-check: closed solid, min. feature 0.3 mm, min. wall 0.5 mm.

• Instant file-repair bot heals 92 % of bad edges; remainder flagged in <15 s. -

AI Quote (30–120 s)

• Geometry classifier decides 2.5-D, 3-D or litho approach.

• Runtime estimator converts mesh to toolpaths with 0.2–0.01 mm adaptive step-over; adds 15 % safety margin.

• Material picker cross-checks stock shelf (aluminium 6061, 5052, brass C360, acetal, FR-4, etc.).

• Dynamic pricing = raw blank + machine hours + consumables + finish; learning model retrained nightly on shop-floor data → ±5 % accuracy vs. final invoice. -

DFM (Engineering sign-off, 2–4 h)

a. Accessibility scan – 3+2 axis reachability map; flags under-cuts >0.4 mm.

b. Thin-wall FEA – predicts chatter risk if L/t > 15; suggests tabs or thicker ribs.

c. Burr forecast – predicts feather burrs on 304 SS if exit angle < 30°; adds chamfer tool.

d. Tolerance budget – allocates 60 % to machining, 25 % to thermal, 15 % to fixturing; proposes datum scheme.

e. Customer PDF + live 3-D viewer issued; one-click approve or request revision loop. -

Production (1–3 days)

• Work order auto-creates bar-code packet: tool list, probe routine, photo-first-article checklist.

• Mini-router cell: Datron Neo 3 kW, 60 k RPM, 0.3 s tool-change, glass-scale feedback.

• Vac-fix or low-melt alloy chuck for 0.02 mm repeatability; in-cycle Renishaw probe compensates tool-wear every 3 parts.

• Adaptive feed & speed AI trims cycle-time 8–20 % while holding spindle load ≤ 85 %.

• First-article laser-scanned against CAD; CpK ≥ 1.67 required before batch release.

• Optional: tumble, anodise type-II, chem-film, passivate, laser mark, assembly. -

Delivery

• Parts ultrasonically cleaned, sealed with VCI paper, 3D-printed snap-fit jig keeps pieces organised.

• Same-day courier within Shenzhen, DHL/UPS 48 h global.

• Digital twin package: full dimensional report, tool-list, video clip of first-article cut; QR code on box links to data for traceability.

End-to-end SLA: 3 days standard, 24 h expedite (no DFM revision) for mini-CNC router jobs.

Start Your Project

Precision prototyping with mini CNC routers from Shenzhen. Contact Susan Leo at info@hy-proto.com.

(Short, professional, and action-oriented—highlights key benefits (precision, prototyping), location credibility (Shenzhen), and clear next step. Ideal for websites, ads, or brochures.)

🚀 Rapid Prototyping Estimator