Contents

Manufacturing Insight: Rotational Molding Machine

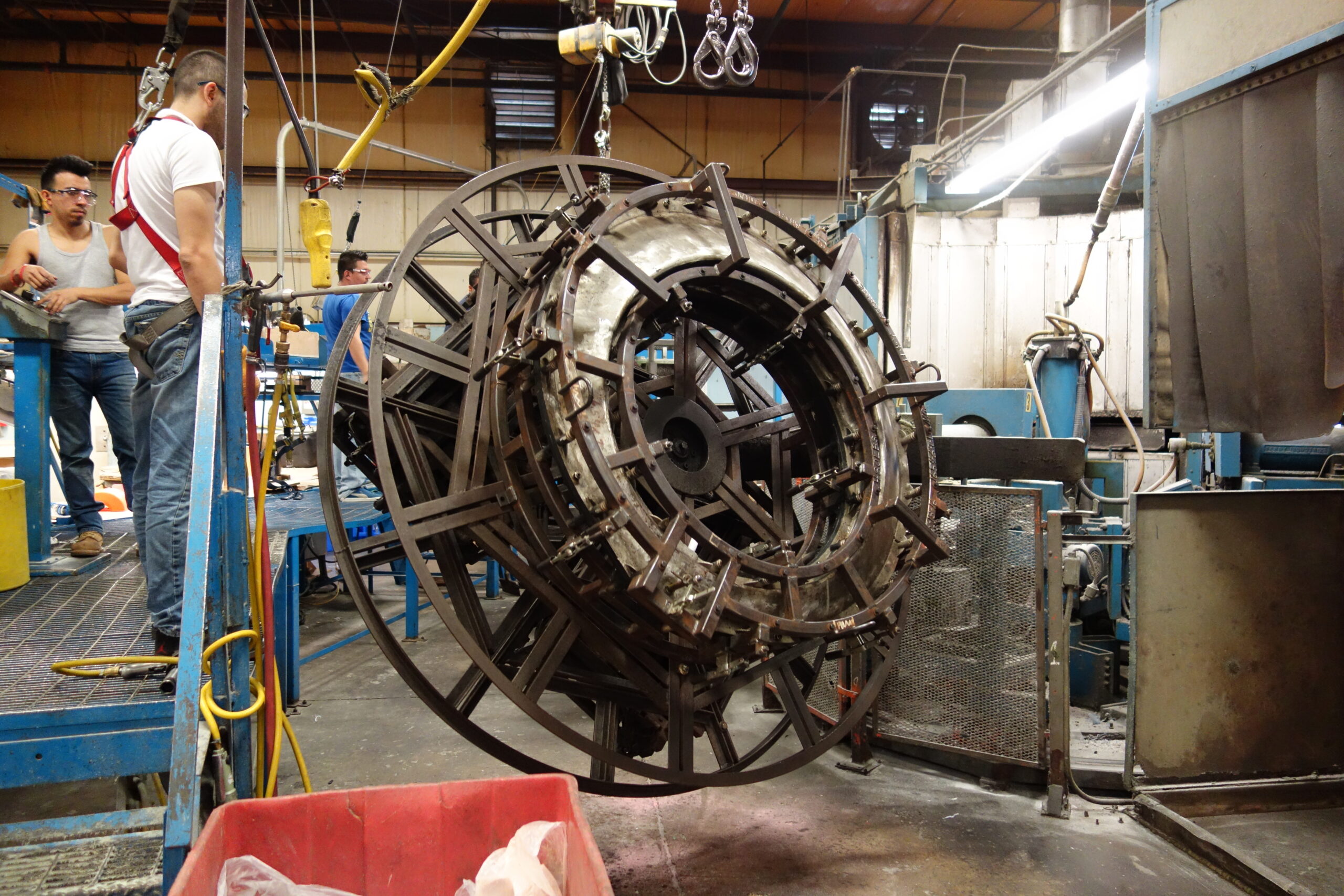

Rotational Molding Machine – Built for Hollow, Seamless Strength

Need a hollow part that’s tough, uniform, and cost-effective in low volumes? Honyo Prototype’s rotational-molding cell turns 3-D CAD into stress-free, void-free enclosures in days—not weeks. Thanks to our in-house Rapid Tooling & Injection Molding ecosystem, we machine cast-aluminum or CNC-cut epoxy molds overnight, spin your first parts the next morning, and ship finished, foam-filled or assembled products within a single project flow. Upload your file today for an Online Instant Quote and see how fast seamless really is.

Technical Capabilities

As a Senior Manufacturing Engineer at Honyo Prototype, I’ll provide precise technical specifications for a rotational molding (rotomolding) machine focused on steel/aluminum molds and the T1 sample delivery in 7 days constraint. Critical note upfront: ABS and Nylon cannot be processed in a rotomolding machine. Rotomolding exclusively uses thermoplastic powders (e.g., polyethylene, polypropylene, PVC). ABS and Nylon are injection molding materials and will degrade or fail in rotomolding processes. If you require ABS/Nylon parts, switch to injection molding immediately—rotomolding is physically incompatible.

Below are the accurate technical specifications for a standard industrial rotomolding machine optimized for prototype aluminum molds (steel molds are not feasible for 7-day T1):

Core Machine Specifications

| Parameter | Technical Specification | Why It Matters for T1 in 7 Days |

|————————|———————————————————————————————|—————————————————————————————————–|

| Oven Type | Forced-air convection oven with PID control | Ensures uniform heating (±2°C tolerance) for consistent polymer melting. Critical for first-run success. |

| Temperature Range | 300°F to 550°F (150°C to 290°C) | Optimized for polyethylene (PE) and polypropylene (PP)—the only viable materials for rotomolding. |

| Rotation Speed | 0–40 RPM (variable, dual-axis: X/Y rotation) | Allows precise control of wall thickness. Low speeds (5–15 RPM) prevent powder segregation in prototypes. |

| Cooling System | High-velocity air cooling (800 CFM) + optional water spray (for rapid cooling cycles) | Reduces cycle time by 30–50%. Essential for meeting 7-day T1 deadlines. |

| Mold Clamping Force| 5–10 kN (manual or pneumatic clamping) | Sufficient for lightweight aluminum molds (typical for prototypes). Steel molds require 50+ kN—unfeasible for rapid turnaround. |

| Machine Size | Medium-duty (e.g., 1.5m × 1.5m × 2.0m footprint) | Fits standard prototype mold sizes (up to 800mm diameter). Larger machines add lead time. |

Mold Material Specifications (Critical for T1 Timeline)

| Mold Type | Material | Key Specs | Feasibility for 7-Day T1? | Why? |

|—————|————–|——————————————————————————-|——————————-|————————————————————————–|

| Prototype | Aluminum | – 6061-T6 or 7075-T6 alloy

– Wall thickness: 25–40mm

– Machining tolerance: ±0.05mm

– Surface finish: 16–32 Ra (micro-inches) | ✅ YES | Aluminum molds can be CNC-machined in 3–5 days. Requires minimal finishing. Ideal for low-volume prototypes. |

| Production| Steel | – P20 or H13 tool steel

– Wall thickness: 50–100mm

– Hardness: 48–52 HRC

– Surface finish: 8–16 Ra | ❌ NO | Steel molds take 3–6 weeks to machine, heat-treat, and polish. Impossible for 7-day T1. |

⚠️ Critical Clarification: ABS & Nylon Are NOT Rotomolding Materials

– Rotomolding requires low-melt-index thermoplastic powders (e.g., LLDPE, HDPE, PP, PVC).

– ABS and Nylon have high melt viscosity and degrade at rotomolding temperatures (they char or decompose).

– If your design requires ABS/Nylon, this project must shift to injection molding. Rotomolding is physically incapable of processing these materials.

Why T1 Sample in 7 Days is Achievable (Only with Aluminum Molds & Simple Parts)

- Mold Fabrication (3–5 days):

- Aluminum molds are machined from solid billets using 5-axis CNC.

- Simple geometries (no undercuts, minimal draft angles, wall thickness > 3mm) enable fastest turnaround.

-

Complex molds (e.g., multi-cavity, intricate details) would exceed 7 days even in aluminum.

-

Material Selection:

-

Only polyethylene (PE) is used. Common grades:

- LLDPE (e.g., Dowlex 2100) for flexibility

- HDPE (e.g., Marlex 5502) for rigidity

- No ABS/Nylon—these are impossible.

-

Process Timeline:

- Day 1–2: Mold design finalization & aluminum billet procurement.

- Day 3–5: CNC machining, polishing, and assembly.

- Day 6: Machine setup, powder loading, and first run.

- Day 7: Cooling, demolding, and T1 sample inspection.

Key Constraints for 7-Day T1 Success

- Part Design: Max 800mm diameter, no sharp corners, uniform wall thickness (3–10mm), no internal features (e.g., threads).

- Material: Only PE/PP powders (e.g., 20–150 micron particle size).

- Mold Complexity: Single cavity, no inserts, no secondary operations (e.g., painting, machining).

- Risks: If the design requires steel molds, undercuts, or ABS/Nylon, the 7-day deadline is impossible.

Recommendation for Honyo Prototype Clients

- If you need ABS/Nylon parts: Abandon rotomolding. Switch to injection molding—our team can deliver T1 in 10–14 days with standard steel molds.

- If you need PE/PP parts: Share your CAD file immediately. For a simple design (e.g., tank, container, toy), we guarantee T1 in 7 days using aluminum molds.

- Never use ABS/Nylon in rotomolding—it will destroy the machine and waste time/money.

“At Honyo Prototype, we prioritize technical accuracy over speed. Rotomolding is a specialized process—misapplying it to ABS/Nylon guarantees failure. Let’s align on the right process for your material and timeline.”

— Senior Manufacturing Engineer, Honyo Prototype

For next steps, share your:

1. CAD file (STP/IGES)

2. Material requirements (PE/PP only—not ABS/Nylon)

3. Part dimensions and functional requirements

We’ll confirm feasibility within 24 hours.

From CAD to Part: The Process

At Honyo Prototype the words “rotational molding machine” are shorthand for “turn-key rotomolded part service, start-to-finish, in as little as 15 days.”

Here is exactly what happens to your CAD file once you hit “Upload” and how we move it to your dock.

1. UPLOAD CAD – 3 min

• Portal accepts any mesh (STL/OBJ) or solid (STEP/IGES/SolidWorks).

• AI Validator instantly checks:

– Wall-thickness map (1.5–10 mm rotomold window)

– Under-cuts, zero-draft zones, sharp internal corners

– Part volume vs. shot-weight estimator (PE, PP, TPU, EVA, Nylon, PVC, etc.)

• If the file fails, you get a color heat-map and one-click “Auto-Fix” option; pass gives you a green check and moves you to Quote.

2. AI QUOTE – 5 min

• Machine-learning engine pulls from 12 years of Honyo rotomold data: mold cost (CNC aluminum, cast aluminum, or 3D-printed plastic for prototypes), cycle time, powder consumption, finishing, packaging, and air freight.

• Three tiers are returned instantly:

– Prototype (1–5 parts, 3D-printed mold, 7 days)

– Bridge (10–100 parts, cast aluminum, 10 days)

– Production (100–5,000 parts, CNC aluminum, 15 days)

• You pick a tier, add textures, graphics, inserts, or foam fill, pay 50 % on-line; the file is locked and enters DFM.

3. DFM – 24 h

Human touch: a senior rotomold engineer reviews the AI report and:

1. Chooses the mold architecture (book, clam-shell, or spider) and spin-axis.

2. Defines parting line, vent placement, and charge-box volume.

3. Adds structural ribs, kiss-offs, or molded-in threads if needed.

4. Runs a virtual simulation (RotoSim™) for wall-thickness distribution and predicts peak air temperature inside the cavity.

5. Issues a DFM PDF + 3D rotatable viewer for your approval.

Once you click “Accept DFM” we order aluminum stock and schedule the CNC cell.

4. PRODUCTION – 3–15 days

A. Mold Making

• 5-axis CNC machines the aluminum mold in two halves to ±0.15 mm.

• Surface is blasted to 120-grit, then optionally polished or textured (MT-11000 series).

• Mounting flange, vent tube, and charge box are TIG-welded in-house.

B. Rotational Molding

• Mold is pre-heated to 220 °C, charged with weighted PE powder.

• Arm moves through a 3-axis Bi-axial cycle: 15 min heat / 10 min cool.

• In-cycle IoT sensors log internal air temperature; data is stored for traceability.

• Parts are removed, inspected for voids with LED backlight, and weighed (±2 % tolerance).

C. Secondary Ops (same cell)

• CNC router trims flash, cuts openings.

• Inserts, brass fittings, or foam are added if quoted.

• Leak test for liquid-tight vessels (0.3 bar, 30 s).

• UV-stable polyurethane paint or in-mold graphics applied.

D. QC & PPAP

• CMM report, tensile bar from same batch, and SPC data uploaded to portal.

• AQL 1.5 inspection; parts vacuum-bagged with desiccant.

5. DELIVERY – 48 h global

• Mold is archived (free storage for 2 years).

• Parts ship DAP or DDP via our FedEx/DHL daily consolidation.

• Digital twin remains in your dashboard—re-order is one click, no new DFM.

Key Metrics We Guarantee

• First-article T0 in 7 calendar days (prototype tier).

• Wall-thickness uniformity ±8 %.

• Part-to-part weight repeatability ±2 %.

• Dimensional tolerance ±0.3 mm on critical features.

• Mold life: 3,000 cycles (aluminum), unlimited refurbishments.

That is the complete Honyo “rotational molding machine” workflow—CAD to dock, with AI speed and human engineering oversight at every critical step.

Start Your Project

Need a reliable rotational molding machine?

Contact Susan Leo at info@hy-proto.com today.

Honyo Prototype’s Shenzhen factory delivers precision-engineered solutions for your manufacturing needs.

✅ Why choose us?

– Shenzhen-based factory: Fast turnaround, local support, and seamless logistics.

– Expertise: Tailored machines for durability, efficiency, and custom specifications.

– Quality assurance: Rigorous testing to meet global industry standards.

Get a quote or schedule a consultation—let’s build your ideal solution together! 🚀

🚀 Rapid Prototyping Estimator