Contents

Manufacturing Insight: Cnc Machine Vs 3D Printer

CNC machining or 3D printing—which one deserves floor space on your next project?

At Honyo Prototype we let you test both answers in real time. Our industrial 3D-printing cells run aerospace-grade polymers, glass- and carbon-filled nylons, flame-retardant UL resins, and quick-sinter metals 24/7, delivering isotropic, tight-tolerance parts in as little as 24 hours. While our 5-axis CNC routers hog out aircraft aluminum and engineering plastics with equal swagger, you can price either route (or a hybrid of both) without waiting for a sales call. Drop an STL or STEP file into our Online Instant Quote portal and see side-by-side CNC and additive costs, lead times, and DfM feedback in under 60 seconds. Honyo’s industrial 3D printing service isn’t just a prototyping perk—it’s a parallel production path, ready to launch when geometry gets too fierce for a cutter or speed beats setup cost.

Technical Capabilities

Technical Specifications Comparison: CNC Machining vs. Additive Manufacturing (SLA, SLS, MJF, DMLS)

As a Senior Manufacturing Engineer at Honyo Prototype, I focus on practical, real-world applicability for prototyping and production. Below is a precise breakdown of key technical specs, material compatibility, and trade-offs for your specific use case. Note: CNC is subtractive (material removal), while SLA/SLS/MJF/DMLS are additive (layer-by-layer building). Materials like Aluminum and Steel cannot be processed by SLA/SLS/MJF—only DMLS or CNC handle metals.

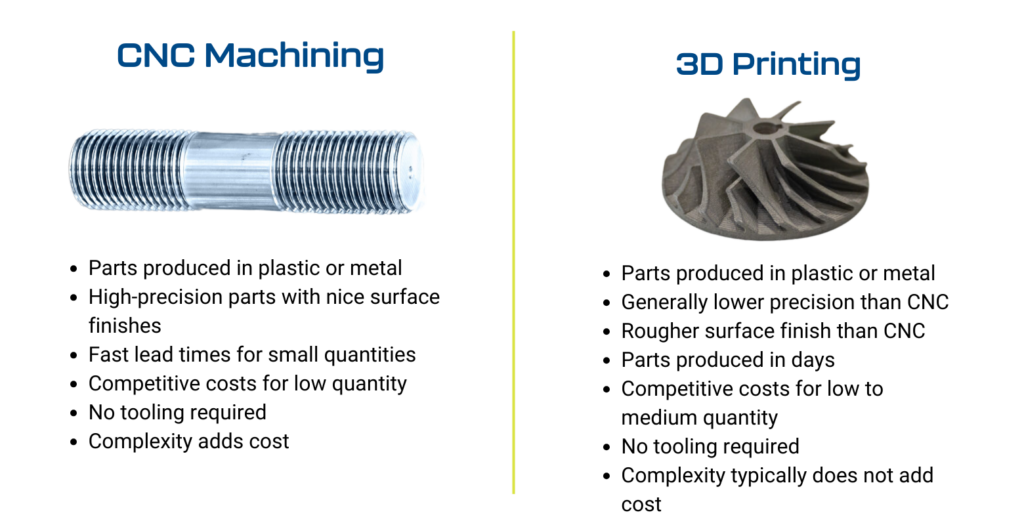

1. CNC Machining Overview

- Process: Subtractive—rotating cutting tools remove material from a solid block (billet or stock).

- Key Specs:

- Tolerances: ±0.005 mm (0.0002″) for precision machining; ±0.025 mm (0.001″) for standard.

- Surface Finish: Ra 0.1–0.8 μm (mirror-polished to rough), achievable without secondary ops.

- Build Volume: Typically 1,000 x 600 x 400 mm (for 5-axis machines); scalable to 5,000+ mm for large parts.

- Speed: Fast for simple geometries (e.g., 1–2 hours for a small aluminum bracket); slower for complex 3D shapes due to toolpath complexity.

- Cost Drivers: Material waste, tooling time, machine hours. High for low-volume metal parts.

- Material Compatibility:

- Aluminum: Excellent (e.g., 6061-T6, 7075). Machinable with high precision, low cost.

- Steel: Excellent (e.g., 304 stainless, 4140 alloy steel). Requires hardened tools but delivers high strength.

- ABS: Good (e.g., extruded ABS sheet), but less common than metals—used for prototypes where metal isn’t needed.

- Nylon: Possible but rare; prone to warping during machining. Better suited for AM processes.

- Best For: Functional metal parts, high-precision components (e.g., aerospace brackets, medical implants), large volumes, or when surface finish > complexity.

2. Additive Manufacturing (AM) Processes

Critical Note: SLA, SLS, and MJF are for polymers only—Aluminum and Steel CANNOT be processed by these. Only DMLS handles metals. ABS is primarily processed via FDM (not listed), while Nylon is core to SLS/MJF.**

A. SLA (Stereolithography)

- Process: UV laser cures liquid photopolymer resin layer-by-layer.

- Key Specs:

- Tolerances: ±0.05 mm (standard); ±0.025 mm (high-res).

- Surface Finish: Smooth (Ra 0.8–2.0 μm), but requires post-curing and support removal.

- Build Volume: Typically 150 x 150 x 150 mm (desktop) to 1,300 x 700 x 500 mm (industrial).

- Speed: Slow for large parts (e.g., 10–20 hours for a 200 mm part); fast for intricate details.

- Cost Drivers: Resin cost, post-processing (cleaning, curing), labor.

- Material Compatibility:

- Aluminum/Steel: ❌ Not possible (resin-based only).

- ABS: ❌ Not used—SLA uses specialized resins (e.g., tough, clear, or flexible).

- Nylon: ❌ Not used—SLA resins are acrylic/epoxy-based; no true Nylon analog.

- Typical Materials: Engineering resins (e.g., ABS-like, polypropylene-like), biocompatible resins, transparent resins.

- Best For: High-detail prototypes (e.g., dental models, jewelry), optical components, visual prototypes. Avoid for functional metal parts or structural plastic parts needing toughness.

B. SLS (Selective Laser Sintering)

- Process: Laser sinters powdered polymer (no supports needed).

- Key Specs:

- Tolerances: ±0.1–0.3 mm (typical); ±0.05 mm achievable with calibration.

- Surface Finish: Matte, grainy (Ra 5–15 μm); requires media blasting for smoothness.

- Build Volume: 300 x 300 x 300 mm (standard) to 750 x 550 x 550 mm (large-format).

- Speed: Moderate (e.g., 15–30 hours for a 200 mm part); batch processing efficient for multiple parts.

- Cost Drivers: Powder cost, energy, post-processing (powder removal, dyeing).

- Material Compatibility:

- Aluminum/Steel: ❌ Not possible (polymer-based only).

- ABS: ❌ Not used—SLS uses nylons or TPU. Some ABS-like powders exist but are rare.

- Nylon: ✅ Core material (e.g., PA12, PA11). Excellent for functional parts.

- Typical Materials: Nylon 12 (PA12), Nylon 11 (PA11), TPU (flexible), glass-filled nylons.

- Best For: Functional prototypes with moving parts (e.g., hinges, gears), end-use parts in automotive/aerospace, complex geometries where supports are impractical. Ideal for Nylon parts needing durability.

C. MJF (Multi Jet Fusion)

- Process: Inkjet deposits fusing agent on powder bed, then IR lamps sinter layers.

- Key Specs:

- Tolerances: ±0.1–0.2 mm (similar to SLS but more consistent).

- Surface Finish: Slightly smoother than SLS (Ra 4–10 μm), but still grainy.

- Build Volume: 380 x 284 x 380 mm (standard HP Jet Fusion systems).

- Speed: Faster than SLS (e.g., 10–20 hours for a 200 mm part) due to parallel processing.

- Cost Drivers: Powder cost, energy, and proprietary fusing agents. Higher upfront cost than SLS but lower per-part cost for volumes.

- Material Compatibility:

- Aluminum/Steel: ❌ Not possible (polymer-based only).

- ABS: ❌ Not used—MJF uses nylons or TPUs.

- Nylon: ✅ Core material (e.g., PA12, PA11). Similar to SLS but with better mechanical properties.

- Typical Materials: Nylon 12 (PA12), thermoplastic polyurethane (TPU), high-temp nylons.

- Best For: High-volume functional parts (e.g., consumer products, medical devices), parts needing consistent mechanical properties. Superior to SLS for production-scale Nylon parts.

D. DMLS (Direct Metal Laser Sintering)

- Process: Laser fuses metal powder layer-by-layer (similar to SLS but for metals).

- Key Specs:

- Tolerances: ±0.05–0.15 mm (typical); ±0.025 mm achievable with post-machining.

- Surface Finish: Rough (Ra 10–25 μm); requires machining/polishing for precision.

- Build Volume: 250 x 250 x 250 mm (small) to 500 x 500 x 500 mm (large).

- Speed: Slow (e.g., 20–40 hours for a 100 mm part); high energy consumption.

- Cost Drivers: Metal powder cost ($50–$200/kg), machine time, post-processing (heat treatment, machining).

- Material Compatibility:

- Aluminum: ✅ Yes (e.g., AlSi10Mg, Al7075). Common for lightweight aerospace parts.

- Steel: ✅ Yes (e.g., 17-4 PH stainless, 316L, tool steels). Used for corrosion-resistant or high-strength parts.

- ABS/Nylon: ❌ Not possible (metal-only process).

- Typical Materials: Aluminum alloys, stainless steels, titanium (Ti64), Inconel.

- Best For: Complex metal parts where CNC is impossible (e.g., internal channels, lattice structures), low-volume aerospace/medical implants, or when material properties > cost. Not cost-effective for simple metal parts—CNC is cheaper for most aluminum/steel geometries.

Key Takeaways for Decision-Making

| Scenario | Recommended Process | Why? |

|——————————————-|——————————|———————————————————————-|

| Aluminum/Steel bracket with tight tolerances | CNC | Lower cost, better surface finish, faster for simple geometries. |

| Complex internal channel in aluminum | DMLS | CNC can’t machine internal features; DMLS builds it in one piece. |

| Functional Nylon gear with moving parts | SLS or MJF | No supports needed; nylon’s toughness beats machined ABS/Nylon. |

| Clear optical prototype | SLA | Only process for high-clarity parts; CNC can’t achieve transparency. |

| High-volume consumer plastic parts | MJF | Faster, more consistent than SLS; lower cost per part at scale. |

💡 Honyo Prototype Insight:

– “For metal parts under $500, CNC is almost always cheaper than DMLS—unless the geometry is impossible to machine (e.g., conformal cooling channels). For Nylon parts, MJF delivers better consistency than SLS for production runs. Avoid DMLS for simple aluminum parts; use CNC instead. SLA is perfect for visual prototypes but avoid for functional use due to brittleness.”

Let me know your specific part requirements—I’ll tailor a recommendation based on your tolerances, volume, and budget! 🛠️

From CAD to Part: The Process

Honyo Prototype – “CNC vs. Additive” workflow

(same 5-step portal, two totally different factories behind it)

-

Upload CAD

One drag-and-drop accepts everything (.step, .stl, .3mf, .sldprt, etc.).

The instant the file hits the server the geometry classifier tags it

– “machinable-prismatic”, “organic-additive”, “mixed”.

Customer selects “CNC quote” or “3D-print quote”; the other branch is hidden. -

AI Quote (30 s)

CNC branch

– Feature recognition extracts pockets, holes, chamfers, 5-axis curves.

– Stock sizing, grip points, tool library and shop-floor calendar are queried.

– Cost = material block + machining hours + deburr + CMM + any special jig.

Additive branch

– Voxel analysis calculates support volume, layer count, anisotropy risk.

– Quotes SLS/MJF/SLM/FDM tiers; automatically flags walls <0.4 mm or overhangs >45°.

Both quotes include real-time raw-material pricing (aluminum 6061, SS316L, PA12, etc.) and freight. -

DFM (24 h)

CNC DFM

– Engineer rotates the part searching for the minimum set-ups (3-axis, 3+2, 5-axis).

– Adds dog-bones, press-in bushings, radii ≥0.5 mm, ±0.025 mm GD&T call-outs.

– Calls out if thin webs (<0.5 mm) should switch to additive.

Additive DFM

– Re-orients to minimise supports, maximise Z-strength, keep surface facing customer visible.

– Snaps in lattice infill, drain holes, 0.2 mm escape channels for unfused powder.

– Recommends heat-treat or infiltration if tolerance <±0.1 mm is required.

Customer approves or iterates in the browser; red/blue zones update live. -

Production

CNC path

– 3-, 4-, 5-axis Haas/DMG/Mazak; Renishaw probing every 3rd op; automatic tool-life logging.

– First-article scan report (GOM ATOS) attached before batch continues.

Additive path

– EOS M290/HP MJF 5200/UnionTech SLA; 30-50 µm layers; nitrogen or argon atmosphere.

– In-process camera & thermal map; every 10th layer auto-compares to .stl.

Both lines converge to 5-stage post-process: support removal, bead-blast/tumble, anodise/dye, laser-mark, CMM final. -

Delivery

Parts vacuum-sealed with silica gel, QC report (material cert, CPK values, photos) in the pouch.

DHL/UPS label auto-generated; portal updates with photos of the actual parts in the box.

Typical door-to-door: CNC 3-5 days, Additive 2-4 days (world-wide).

Key takeaway: one upload, one portal, but from step-2 onward the job rides on two completely independent manufacturing rails optimised for the physics of cutting vs. growing.

Start Your Project

Still deciding between CNC machining and 3D printing?

Contact Susan Leo at info@hy-proto.com for expert guidance from Honyo Prototype’s Shenzhen factory — precision manufacturing tailored to your project needs.

Engineer your solution with confidence. Let’s build it together. 🛠️

🚀 Rapid Prototyping Estimator