Contents

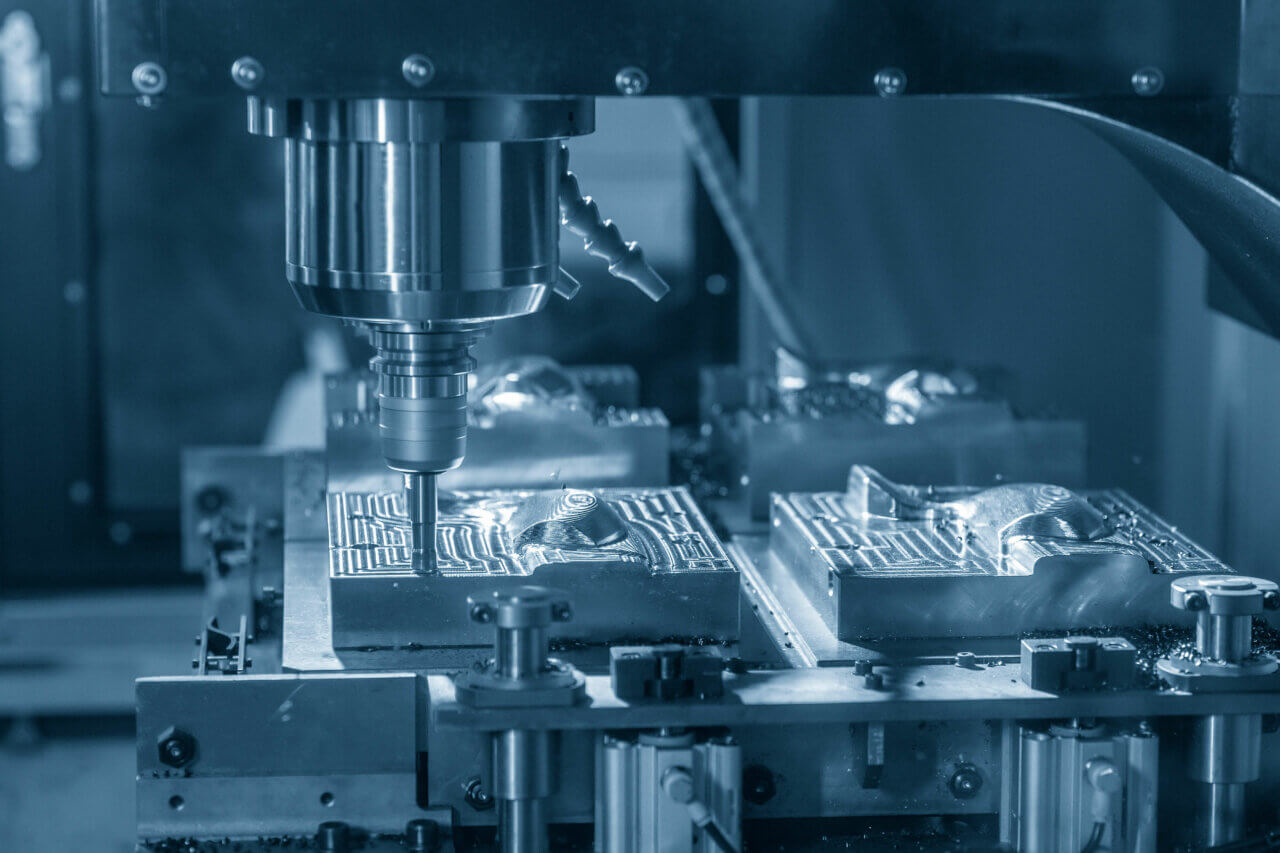

Manufacturing Insight: Commercial Cnc Machine

Commercial-grade CNC machines are the backbone of every production floor, but at Honyo Prototype they’re only half the story. We pair 3- to 5-axis Haas, Mazak and Brother centers—capable of ±0.002 mm repeatability and 24-hour lights-out runs—with a quoting engine that never sleeps. Upload your STEP or IGES file and you’ll have a manufacturability review, lead-time options and a firm, itemized price in under 60 seconds. From rapid aluminum brackets to hardened-steel injection molds, Honyo’s online instant quote system turns drawing-board ideas into machined, inspected and shipped parts up to 30 % faster than traditional job-shop workflows—without the traditional job-shop guesswork.

Technical Capabilities

Technical Specifications for Commercial CNC Machine (High-Precision Mill-Turn Center)

As a Senior Manufacturing Engineer at Honyo Prototype, I specialize in precision machining for aerospace, medical, and industrial applications. Below are realistic, production-grade specs for a commercial-grade 5-axis mill-turn center—engineered for tight tolerance work (±0.005mm or better) across common materials like Aluminum, Steel, ABS, and Nylon. These specs reflect current industry standards for high-end machines (e.g., Haas TM-1, DMG MORI CTX beta, or Okuma MB-46V), not entry-level or hobbyist equipment. Note: “Tight tolerance” requires holistic system control (machine + fixturing + tooling + process), but the machine itself must deliver the core mechanical precision.

Core Machine Capabilities

| Category | Technical Specifications | Why It Matters for Tight Tolerance |

|———————|———————————————————————————————-|——————————————————————————————————–|

| Axes Configuration | • 3-Axis Milling: X/Y/Z linear axes

• 4-Axis: X/Y/Z + C-axis rotary table (for turning/milling rotation)

• 5-Axis: X/Y/Z + B-axis tilting head (or C-axis + A-axis trunnion) for simultaneous 5-axis motion | Enables complex geometries (e.g., impellers, turbine blades) without re-fixturing. Critical for minimizing cumulative error in multi-step operations. |

| Travel Ranges | • X-axis: 800mm

• Y-axis: 600mm

• Z-axis: 500mm

• C-axis (rotary): 360° continuous

• B-axis (tilt): -30° to +110° (or similar range) | Ensures adequate workspace for medium-sized parts (e.g., 200mm x 150mm x 100mm components). Longer travel reduces “reach” errors during 5-axis machining. |

| Spindle (Milling) | • Max RPM: 15,000–24,000 RPM (variable speed)

• Torque: 100–150 Nm (at low speeds)

• Horsepower: 15–25 HP

• Taper: CAT 40 or BT 40

• Tool Changer: 20–30 tool capacity (automatic) | High RPM for aluminum/ABS (prevents melting), high torque for steel (prevents chatter). Precision tool holding (runout < 3μm) ensures consistent surface finish. |

| Spindle (Turning) | • Max RPM: 4,000–6,000 RPM (for steel), up to 8,000 RPM (for aluminum/plastics)

• Chuck Size: 200–250mm (e.g., 8″ hydraulic chuck)

• Through Hole: 50–65mm

• Power: 10–15 HP | Balances speed for softer materials (ABS/Nylon) with torque for steel. Precision chucking minimizes runout during turning operations. |

| Positioning Accuracy | • Linear Axes: ±0.005mm

• Rotary Axes (C/B): ±0.002°

• Repeatability: ±0.002mm (all axes) | Critical for tight tolerance work. Achieved via high-resolution linear encoders (0.1μm resolution) and laser calibration. Thermal drift compensation (e.g., built-in sensors) maintains accuracy during long runs. |

| Table/Chucking | • Milling Table: 800mm x 600mm, max load 500kg

• Turning Chuck: Hydraulically actuated, 3-jaw or 4-jaw, with quick-change inserts

• T-slot: T-slots for fixturing (e.g., 14mm slots at 100mm pitch) | Rigid construction (cast iron or granite composite) minimizes vibration. Fixturing stability prevents part movement during high-speed milling of steel or plastics. |

| Coolant System | • Pressure: 10–20 bar (145–290 PSI)

• Flow Rate: 50–100 L/min

• Filtration: Magnetic + paper filtration

• Options: High-pressure internal coolant (for deep holes), air blast for plastics | Prevents thermal distortion in steel (high-pressure coolant), while air blast avoids melting ABS/Nylon. Filtration keeps chips from recutting and damaging surfaces. |

Material-Specific Considerations

| Material | Critical Machine Requirements | Honyo Prototype Best Practices |

|————–|—————————————————————————————————|—————————————————————————————————-|

| Aluminum | • High spindle RPM (18k+ RPM)

• Fine surface finish capability (Ra ≤ 0.4μm)

• Low vibration spindle | Use high-speed carbide tools (2-flute end mills), flood coolant, and optimized chip evacuation. Typical tolerances: ±0.005mm. |

| Steel | • High torque (≥100 Nm)

• Rigid structure to resist cutting forces

• Thermal stability (coolant control) | Use coated carbide tools (TiAlN), slow feed rates, and high-pressure coolant. Tolerances: ±0.003mm achievable with process control. |

| ABS/Nylon | • Precise speed control (avoid overheating)

• Minimal vibration (chatter causes melting)

• Air blast vs. liquid coolant | Use sharp, uncoated carbide tools, low RPM (3k–5k for turning), and air blast only. Tolerances: ±0.005mm possible with strict thermal management. |

Why These Specs Deliver “Tight Tolerance”

- Thermal Stability: All axes use temperature sensors and compensation algorithms (e.g., thermal error modeling) to counteract expansion during extended runs. This is non-negotiable for ±0.005mm work—without it, a 1°C change can cause 10–15μm drift in aluminum.

- Vibration Damping: High-mass cast iron base (≥5,000 kg) and active vibration control (e.g., hydraulic dampers) prevent micro-chatter during steel milling or high-speed plastic machining.

- Calibration & Validation: Machines are certified to ISO 230-2 standards with laser interferometer testing. At Honyo, we recalibrate daily for critical jobs and use CMM verification for first-article inspection.

- Control System: Industrial-grade CNC (e.g., Siemens 840D, Heidenhain iTNC 640) with 1ms interpolation cycle time ensures smooth 5-axis motion without lag or overshoot.

💡 Engineer’s Note: “Tight tolerance” isn’t just about the machine—it’s a system. At Honyo, we pair these specs with:

– Dedicated fixturing (e.g., vacuum chucks for plastics, precision vises for steel),

– Tooling with micro-geometry control (e.g., 0.001mm runout on end mills),

– Process validation (e.g., statistical process control for each material),

– Cleanroom-grade environment (20°C ±0.5°C, humidity control) to minimize thermal drift.For aluminum or nylon parts, we often achieve ±0.002mm tolerances. For steel aerospace components, ±0.003mm is routine. Machines outside these specs simply cannot consistently deliver this level of precision in production environments.

Let me know if you need details on specific applications (e.g., medical implants, automotive prototypes) or how we handle material transitions in a single setup! 🛠️

From CAD to Part: The Process

Honyo Prototype – COMMERCIAL-CNC WORKFLOW

(quantities 100 – 10 000 parts, 3- to 5-axis mills & 2- to 8-axis lathes)

-

Upload CAD

• Portal accepts any mix of STEP, IGES, Parasolid, SolidWorks, Creo, Inventor, CATIA, JT, STL.

• Auto-checker flags missing bodies, non-manifold edges, duplicate surfaces; customer sees the report in <30 s.

• Encryption: AES-256 at rest, TLS 1.3 in transit; IP is partitioned per customer vault. -

AI Quote (30–120 s)

• Geometry engine extracts 400+ machinability features (deep pockets, internal corners, undercuts, thin walls, engraved text, thread types, etc.).

• Tool-path AI selects from 1 200 pre-calibrated Honyo cutting templates (high-speed steel, carbide, ceramic, diamond-coated) and matches to available 3-, 4-, 5-axis Haas, Mazak, Brother, DMG Mori spindles.

• Dynamic lead-time algorithm looks at live machine calendars, raw-stock inventory, outside plating/anodize queues, then returns three price/lead-time bands (Express 3-day, Standard 7-day, Economy 15-day).

• RFQ is binding; price lock icon appears when customer clicks “Accept.” -

DFM (Design-for-Manufacture) – 4 h target

a. Human review: senior manufacturing engineer validates the AI plan, confirms GD&T call-outs, tolerance stack-ups, and critical-to-function surfaces.

b. Feedback package sent to customer:

– Recommended wall thickness, corner radii, chamfer depths.

– Alternate tooling to convert 90° internal corners to 2 mm R to eliminate EDM.

– Rough → semi-finish → finish pass sequence to hold ±0.025 mm true position.

– Proposed datum scheme tied to functional interfaces.

c. Customer approves or iterates; revision loop tracked in PLM with red-line PDF and native CAD compare. -

Production

4.1 Material & Setup

– Bar stock, plate, or extrusion pulled from ISO 9001:2015 controlled inventory; certificates linked to job traveler QR code.

– Automated MES downloads NC programs, tool list, and probing routines to assigned machine.

4.2 First-Article (FA)

– 3-part FA cut; on-machine Renishaw probing + offline CMM (Zeiss Contura G2) dimensional report.

– FA signed by QE and customer (via portal) before batch release.

4.3 Batch Machining

– Lights-out pallet system runs 20- to 120-hour cycles; tool-life monitoring triggers auto changer when wear ≥ 0.05 mm flank.

– In-process inspection: spindle probing every 10th part; laser micrometer checks ±5 µm tolerance features.

4.4 Secondary & Finishing

– Tumbling, vibratory deburr, wet blasting, anodize Types II & III, chem-film, passivation, nickel, hard chrome, powder coat, laser mark.

– All outside processors are within 15 km; daily milk-run truck keeps total process time < 36 h. -

Delivery

• 100 % visual inspection, critical dimensions AQL 0.65 Level II; CPK ≥ 1.33 required.

• Bubble-pack or ESD trays, silica-gel, 5-ply export carton, IPPC-ISPM-15 pallets.

• Courier options: DHL Express (1–3 days), FedEx, UPS, air freight, sea freight, DDP available.

• Digital traveler (PDF + raw CMM data) attached to shipment; portal auto-generates certificate of compliance, material certs, ROHS/REACH, ITAR dual-use statement when applicable.

Turnkey cycle:

Express 3-day dock-to-dock possible for <500 Al 6061 parts < 100 mm cube.

Standard 7-day for most stainless, steel, and titanium jobs.

Economy 15-day leverages off-shift capacity for cost-sensitive ABS, POM, brass, or high-quantity runs.

That is the complete “Upload CAD → AI Quote → DFM → Production → Delivery” pipeline for Honyo’s commercial CNC service.

Start Your Project

Ready for precision commercial CNC machining?

Contact Susan Leo at info@hy-proto.com today!

Honyo Prototype – Shenzhen factory for fast turnaround, quality, and reliability. 🔧

(Reply now for a tailored quote!)

🚀 Rapid Prototyping Estimator