Contents

Manufacturing Insight: Low Melting Point Metals For Casting

When your prototype calls for low-melting-point metals—think tin, zinc, or lead-bismuth alloys—Honyo Prototype brings the same precision we’re famous for in sheet-metal fabrication to every casting job. Our in-house die-casting cells are fed by high-speed laser-cut and CNC-formed molds that originate on the same sheet-metal lines that produce millions of brackets, shields, and enclosures each year. The result is net-shape castings with the tight tolerances and crisp features you’d expect from a sheet-metal leader, but in alloys that flow at temperatures as low as 138 °C. Need numbers today? Upload your 3-D file and select “Low-Temp Casting” for an Online Instant Quote—prices, lead-time, and DFM feedback in under 60 seconds.

Technical Capabilities

Important Clarification First:

Your query contains a critical misunderstanding. Low-melting-point metals for casting (e.g., tin, lead, zinc, bismuth alloys) are NOT used for laser cutting, bending, or welding. These processes are incompatible with such materials due to their extremely low melting points (typically 50–250°C). Attempting laser cutting, bending, or welding on these metals would cause immediate melting, deformation, or vaporization—making the processes physically impossible.

Additionally:

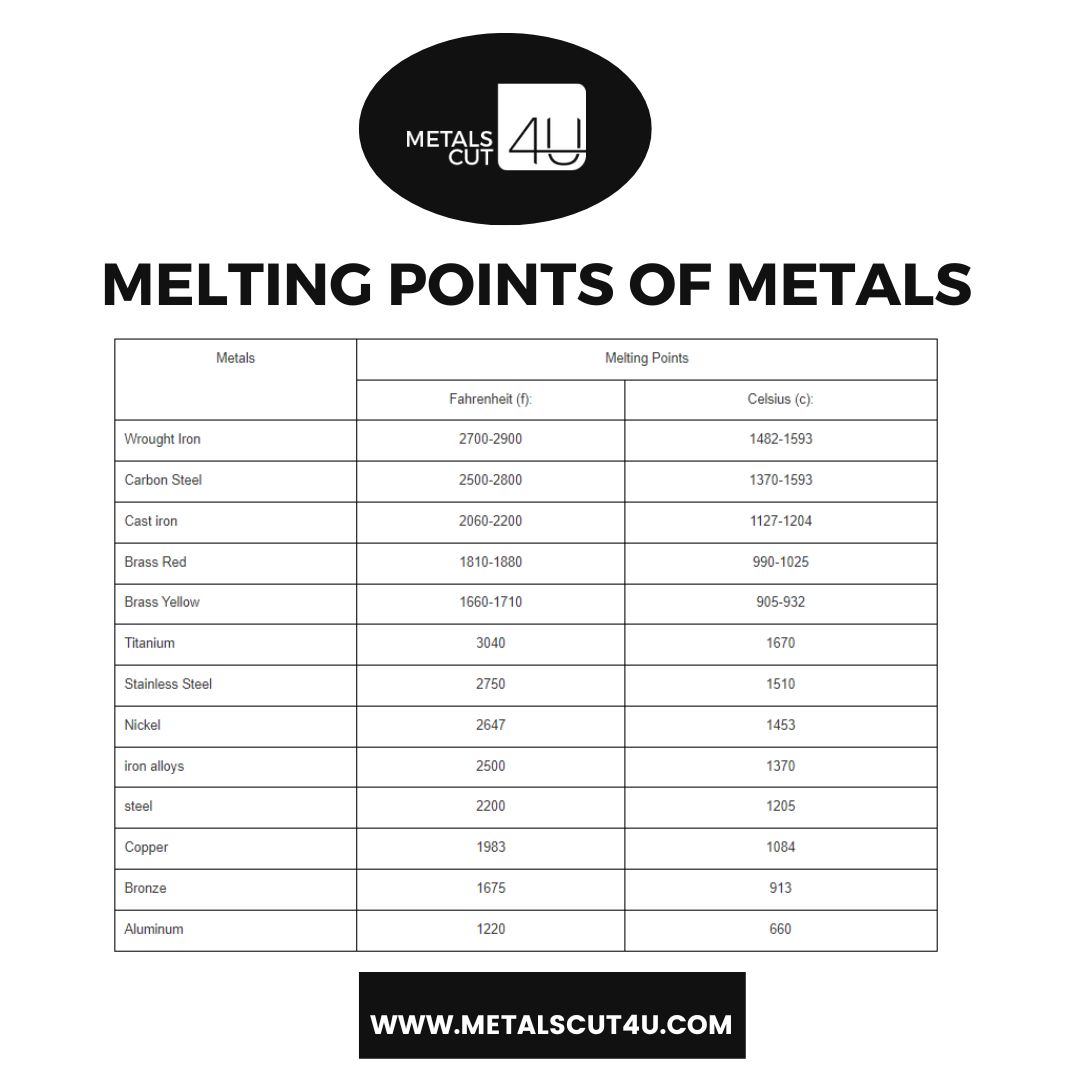

– Aluminum and Steel are NOT low-melting-point metals (Al: 660°C, Steel: 1370–1530°C). They are high-melting-point metals used in sheet metal fabrication (laser cutting, bending, welding).

– ABS and Nylon are PLASTICS, not metals. They have no relevance to “metal casting” and cannot be welded using metal welding techniques.

I’ll address both scenarios clearly:

1. Why low-melting-point metals for casting CANNOT be processed via laser cutting, bending, or welding.

2. Technical specs for Aluminum, Steel, ABS, and Nylon as requested—but only for their actual applications (not casting).

🔥 Part 1: Low-Melting-Point Metals for Casting (e.g., Wood’s Metal, Cerrobend, Field’s Metal)

(Note: These are used for casting patterns, not fabrication)

– Typical Melting Points: 50–250°C (e.g., Wood’s Metal: 70°C, Cerrobend: 70°C, Bismuth-Tin alloys: 138–150°C).

– Why Laser Cutting, Bending, and Welding Are IMPOSSIBLE:

– Laser Cutting: The laser beam (even low-power) instantly melts/vaporizes these metals. No clean cut is achievable—only chaotic melting.

– Bending: These metals are too soft (e.g., pure tin is as soft as butter). Any mechanical force causes permanent deformation, not controlled bending.

– Welding: No standard welding process (TIG, MIG, etc.) works. The metal melts before the arc can form. “Welding” here would require soldering with temperatures below 100°C—not structural welding.

– Actual Use Case: These alloys are cast into molds (e.g., for investment casting patterns, prototyping, or low-temperature molds). They are never fabricated after casting.

💡 Key Takeaway: Low-melting-point casting alloys are not sheet metals. They are poured into molds as liquids and solidify into final shapes. No post-casting fabrication is possible.

⚙️ Part 2: Technical Specs for Requested Materials (Corrected Context)

Note: These specs apply to sheet metal fabrication (for Al/Steel) or plastic processing (for ABS/Nylon)—NOT casting. Low-melting-point metals are irrelevant here.

A. Aluminum (e.g., 6061-T6 Sheet Metal)

- Melting Point: 660°C

- Laser Cutting:

- Power: 1–3 kW (for 3–6mm thickness).

- Assist Gas: Nitrogen (for clean edges) or Oxygen (for thicker sections).

- Speed: 1–5 m/min (depends on thickness).

- Challenges: High thermal conductivity causes heat distortion; requires precise focus control.

- Bending:

- Minimum Bend Radius: 1× material thickness (for 6061-T6).

- Springback: 1–3° (requires overbending compensation).

- Tooling: Hardened steel dies (avoid aluminum adhesion).

- Welding:

- Processes: TIG (best for thin sheets), MIG (for thicker sections).

- Preheat: Not required for thin sheets (<6mm), but recommended for thick sections.

- Shielding Gas: 100% Argon.

- Challenges: Oxide layer causes poor fusion; requires high cleaning before welding.

B. Steel (e.g., Mild Steel A36 Sheet)

- Melting Point: ~1370–1530°C (varies by alloy).

- Laser Cutting:

- Power: 1–6 kW (for 1–20mm thickness).

- Assist Gas: Oxygen (for carbon steel) or Nitrogen (for clean cuts on thin sheets).

- Speed: 0.5–5 m/min (thicker sections slower).

- Bending:

- Minimum Bend Radius: 0.5–1× material thickness (for mild steel).

- Springback: 0.5–1° (easier to control than aluminum).

- Welding:

- Processes: MIG (most common), Stick (SMAW), Flux-Cored.

- Preheat: Required for high-carbon steels or thick sections (>10mm).

- Shielding Gas: CO₂ or Argon/CO₂ mix (75/25).

C. ABS (Acrylonitrile Butadiene Styrene – Plastic)

- Melting Point: ~221°C (softening point: 105°C).

- Laser Cutting:

- Power: 30–100W (CO₂ laser).

- Speed: 5–20 mm/s (for 3mm thickness).

- Assist Gas: Air (low pressure).

- Critical Note: Releases toxic fumes (HCN, CO) – requires industrial exhaust ventilation. Edges may melt slightly.

- Bending:

- Requires heat bending (e.g., 120–150°C with a heat gun or oven).

- Minimum Bend Radius: 2–3× material thickness (to avoid cracking).

- Welding:

- No metal welding possible!

- Plastic welding methods:

- Ultrasonic welding (for small parts).

- Solvent welding (using acetone or ABS cement).

- Hot-air welding (for larger joints).

D. Nylon (e.g., PA6 or PA66 – Plastic)

- Melting Point: 220–265°C (varies by grade).

- Laser Cutting:

- Power: 40–120W (CO₂ laser).

- Speed: 3–15 mm/s (for 3mm thickness).

- Assist Gas: Air (low pressure).

- Critical Note: Releases irritating fumes; requires ventilation. Edges may char.

- Bending:

- Requires heat bending (140–180°C).

- Minimum Bend Radius: 3–5× material thickness (brittle when cold).

- Welding:

- No metal welding possible!

- Plastic welding methods:

- Ultrasonic welding (for small parts).

- Hot-plate welding (for larger assemblies).

- Solvent bonding (limited use; weak joint).

✅ Summary & Recommendations

| Material | Casting? | Laser Cutting | Bending | Welding |

|—————-|———-|—————|———|———|

| Low-MP Metals (e.g., Wood’s Metal) | ✅ Yes | ❌ Impossible | ❌ Impossible | ❌ Impossible |

| Aluminum | ❌ No | ✅ Yes | ✅ Yes | ✅ TIG/MIG |

| Steel | ❌ No | ✅ Yes | ✅ Yes | ✅ MIG/Stick |

| ABS | ❌ No | ✅ Yes (with ventilation) | ✅ Heat bending | ✅ Ultrasonic/Solvent |

| Nylon | ❌ No | ✅ Yes (with ventilation) | ✅ Heat bending | ✅ Ultrasonic/Hot-plate |

- If you need casting alloys: Specify the casting process (e.g., investment casting, sand casting) and the application (e.g., prototype, mold, low-temp casting). I’ll provide specs for casting parameters (e.g., pouring temperature, mold design).

- If you need fabrication specs: Confirm whether you’re working with sheet metal (Al/Steel) or plastics (ABS/Nylon)—and I’ll refine the details.

💡 Honyo Prototype Recommendation: Always clarify the process and material category first. Low-melting-point metals for casting are fundamentally different from sheet metal or plastics. Mixing these concepts risks costly errors (e.g., trying to laser-cut tin alloy will destroy your machine). Let’s discuss your actual project goals!

For further details, share:

– Your specific application (e.g., “prototyping a heat sink,” “making a plastic housing,” “investment casting pattern”).

– Material thickness and part dimensions.

– Desired process (casting, laser cutting, bending, welding).

I’m here to help! 😊

From CAD to Part: The Process

Honyo Prototype – Low-Melting-Point Metal Casting Workflow

(Al-, Zn-, Mg-based alloys; typical pour window 380 °C – 650 °C)

-

Upload CAD

• Portal accepts STEP, IGES, Parasolid, SolidWorks, Creo, Inventor, STL.

• Auto-checker flags zero-thickness, non-manifold edges, missing drafts.

• Instant feedback: “Cast-friendly?” traffic-light (green / amber / red). -

AI Quote (≤ 30 s)

• Geometry engine extracts volume, surface area, under-cuts, core count.

• Alloy selector ranks 3 candidates by strength vs. cost vs. lead-time.

• Tooling solver chooses:

– Single-cavity steel insert (≥ 500 shots)

– Multi-cavity H-13 (≥ 5 k shots)

– 3D-printed sand or SLA master (≤ 50 shots)

• Secondary ops (CNC trim, tumble, anodise, impregnation) auto-added.

• Output: interactive quote with 3 price breaks & 3 delivery options. -

DFM (24 h engineering package)

3.1 Feeding & solidification simulation (MAGMA / FLOW-3D)

– Gate velocity < 55 m s⁻¹ (Al) to avoid oxide entrainment.

– Feeding distance ≥ 1.2 × wall thickness; riser volume ≥ 25 % shrinkage.

3.2 Parting-line & draft optimisation

– ≥ 1° draft on inside walls, ≥ 0.5° on outside for Zn.

3.3 Shrinkage & machining allowance

– Al 0.4 %, Zn 0.6 %, Mg 0.8 % linear.

3.4 Tolerance review

– Standard ISO 8062-CT6 for as-cast; CT4 achievable with post-CNC.

3.5 Rapid tool design

– P20 or H-13 inserts, 840 °C nitride, cycle target 45 s (Zn) / 90 s (Al).

Customer signs off DFM report & 3D tool layout before steel cut. -

Production

4.1 Tool manufacture (3–7 days)

– CNC hard-mill to ± 0.02 mm, polish to Ra 0.4 µm on flow surfaces.

4.2 Die-cast cell set-up

– 280 t Buhler for ≤ 0.7 kg Al, 420 t for ≤ 1.5 kg Al, 160 t for Zn.

– Closed-loop shot system: real-time biscuit thickness & cavity pressure.

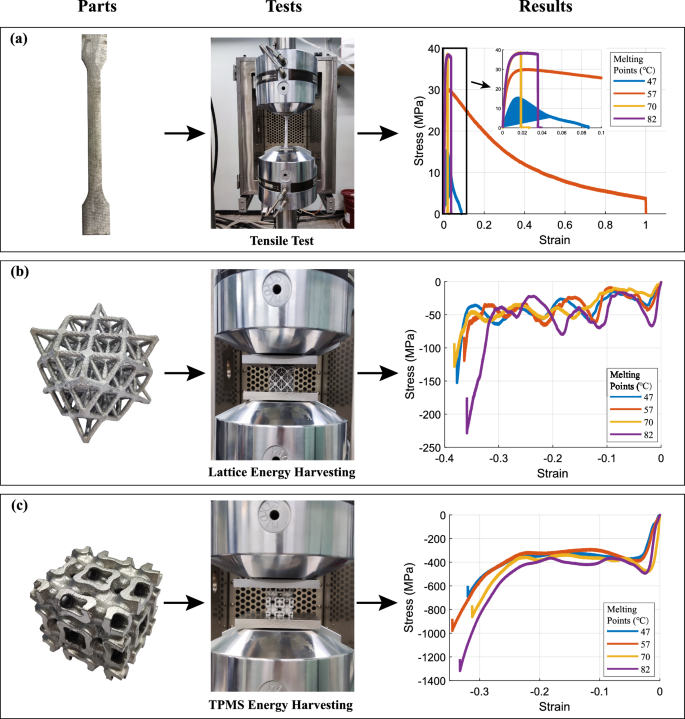

4.3 Process window validation

– 5-shot DOE: melt 680 °C, die 180 °C, intensification 800 bar.

– X-ray & CT check porosity ≤ 2 % in critical zone.

4.4 Secondary operations

– Trim press + CNC 3-axis for datum & seal groove (± 0.05 mm).

– Impregnation (MIL-I-17563) if leak test < 10⁻⁵ mbar L s⁻¹ required.

– T6 heat-treat (Al) or vibratory finish (Zn) per spec.

4.5 In-line SPC

– CpK ≥ 1.33 on key dimensions every 2 h; data uploaded to customer portal. -

Delivery

• 5-day standard (Al), 3-day (Zn) ex-tool approval.

• PPAP Level 3 pack: material cert, COC, dimensional report, X-ray map, RoHS.

• Vacuum-sealed + VCI film; shock-resistant export carton; DDP or FCA Incoterms.

• Portal tracking with photos of 1st article, packing list, and courier AWB.

Typical lead-time summary

Upload → AI quote → DFM approval → T0 parts in hand

Al alloys: 7–9 days

Zn alloys: 5–7 days

Start Your Project

Need low melting point metals for casting?

Honyo Prototype’s Shenzhen-based factory delivers precision, energy-efficient solutions for intricate designs and cost-effective production.

Contact Susan Leo today at info@hy-proto.com for a custom quote!

Engineered for excellence. Delivered globally. 🌏

🚀 Rapid Prototyping Estimator