Contents

Manufacturing Insight: Cnc Router Automatic Tool Changer

Manufacturing Insight: CNC Router Automatic Tool Changer Technology

Automatic Tool Changers (ATCs) represent a critical advancement in CNC router efficiency, fundamentally transforming production throughput and operational capability for complex prototyping and low-volume manufacturing. By automating the tool exchange process, ATCs eliminate manual intervention during machining cycles, significantly reducing non-cutting time and enabling unattended operation for extended periods. This capability is essential for producing intricate parts requiring multiple operations—such as profiling, drilling, engraving, and 3D contouring—within a single machine setup. At Shenzhen Honyo Prototype, we integrate high-performance ATC systems across our CNC router fleet to deliver accelerated project turnaround without compromising dimensional accuracy or surface finish quality.

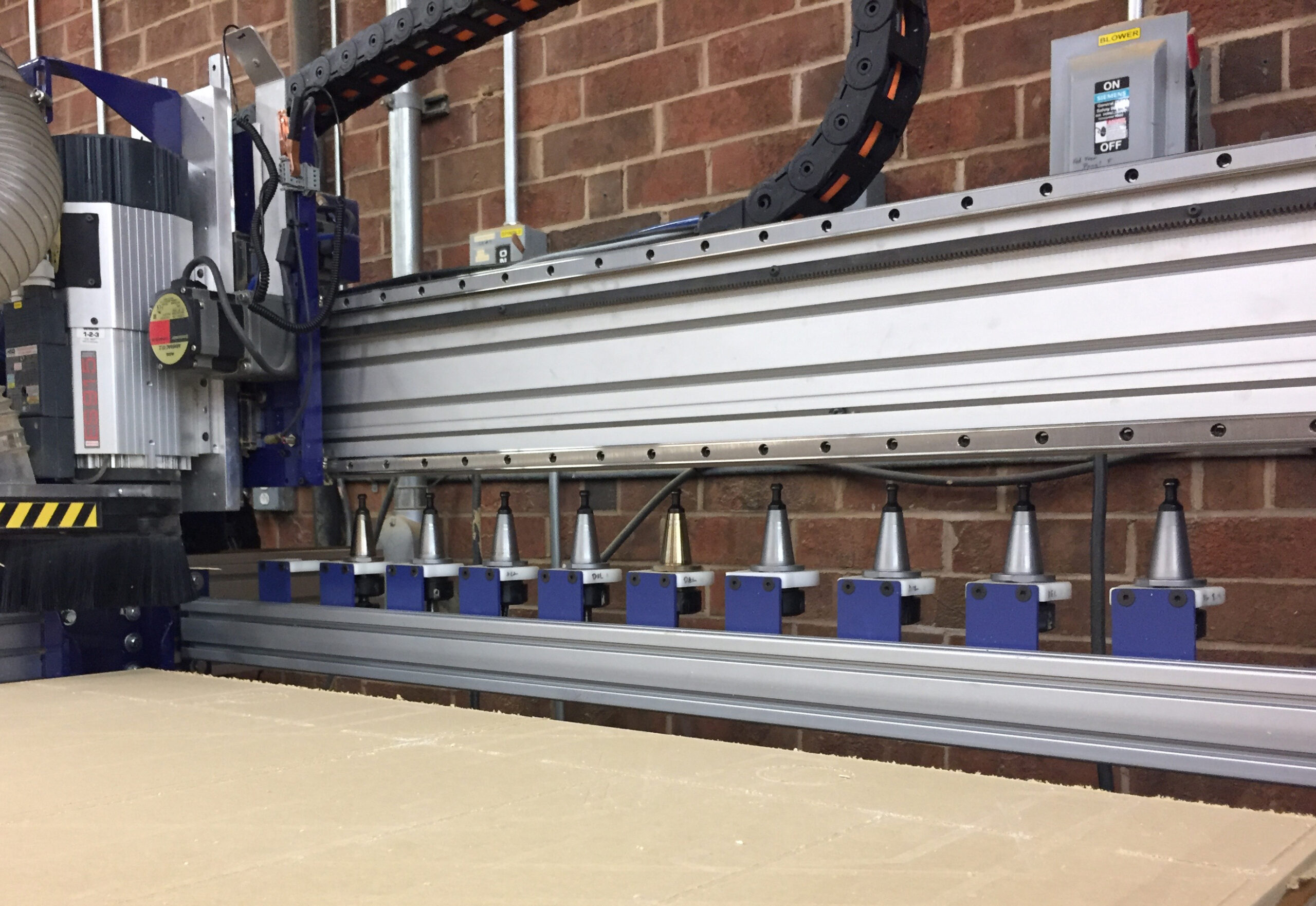

The core functionality of an ATC involves a tool magazine (typically carousel or linear rack style) that stores pre-loaded cutters. When a tool change is commanded by the CNC program, the spindle retracts to a predefined position. The changer arm then executes a precise sequence: retrieving the current tool from the spindle, depositing it into the magazine, selecting the next required tool, and mounting it securely into the spindle. Advanced systems incorporate tool length sensors and breakage detection to ensure process reliability and maintain tight tolerances throughout the machining sequence. This automation minimizes human error, optimizes machine utilization, and supports the execution of highly complex, multi-tool programs that would be impractical or time-prohibitive with manual changes.

Honyo Prototype leverages ATC technology to enhance our service delivery for demanding client projects. Our integrated systems undergo rigorous calibration and maintenance protocols to guarantee consistent performance under production conditions. We specialize in optimizing ATC workflows for rapid prototyping, ensuring that complex geometries requiring diverse tooling strategies—such as multi-axis composite machining or fine-detail wood/metal fabrication—are completed efficiently within quoted lead times. This capability directly translates to reduced project costs for clients and enables the economical production of parts that would otherwise necessitate multiple machine setups or secondary operations.

Key performance specifications of our standard ATC-equipped CNC routers are summarized below:

| Parameter | Honyo Standard Range | Key Benefit |

| :——————— | :——————- | :——————————————- |

| Tool Capacity | 12 – 30 tools | Supports complex multi-operation workflows |

| Average Tool Change Time | 1.5 – 3.0 seconds | Maximizes spindle uptime and throughput |

| Positioning Accuracy | ±0.005 mm | Ensures dimensional integrity across tool changes |

Implementing ATCs is not merely a feature upgrade; it is a strategic investment in manufacturing agility. For clients requiring high-mix, low-volume production or intricate prototypes, Honyo’s ATC-enabled CNC routers deliver measurable productivity gains of 20-30% compared to manual tool change processes. This efficiency allows us to accommodate tighter deadlines while maintaining our stringent quality standards. By eliminating setup bottlenecks, our ATC systems enable the seamless execution of sophisticated machining strategies, making them indispensable for modern rapid prototyping and precision manufacturing demands. Partnering with Honyo ensures access to this technology, expertly applied to accelerate your product development lifecycle.

Technical Capabilities

CNC Router Automatic Tool Changer – Technical Capabilities

At Shenzhen Honyo Prototype, our CNC router systems equipped with automatic tool changers (ATC) are engineered to deliver precision, efficiency, and versatility across complex machining operations. Designed for high-performance 3-axis, 4-axis, and 5-axis milling applications, our ATC-enabled routers streamline production by minimizing downtime during tool transitions, enabling uninterrupted multi-operation workflows. These systems are ideal for prototyping and low-to-mid volume production runs requiring tight tolerances, intricate geometries, and material adaptability.

Our ATC systems support rapid tool exchange with repeatability within ±0.005 mm, ensuring consistent accuracy throughout the machining cycle. The integrated tool magazine accommodates up to 12 tools as standard, with optional configurations supporting up to 24 tools depending on machine model and application needs. Tool change times average between 2.5 to 4 seconds, optimizing cycle efficiency without compromising precision. Each tool station is pneumatically or servo-driven, ensuring reliable positioning and long-term durability under continuous operation.

The CNC routers are compatible with a wide range of materials, including engineering plastics, aluminum alloys, brass, copper, wood composites, and high-density foam. When combined with our high-torque spindles (ranging from 8,000 to 24,000 RPM), the ATC systems maintain tight tolerances as close as ±0.01 mm for critical features. This level of accuracy is sustained across all three linear axes and rotational axes (when applicable), making the platform suitable for complex 5-axis simultaneous machining of aerospace components, medical device housings, and precision molds.

For turning-milling hybrid operations, our 4-axis and 5-axis configurations integrate live tooling capabilities, allowing for synchronized milling and turning in a single setup. This reduces part handling, improves concentricity, and enhances dimensional consistency. The CNC control systems utilize advanced path prediction and adaptive feed algorithms to maintain surface finish quality and tool life, even during high-speed contouring.

All ATC-equipped machines are calibrated using laser measurement systems and undergo rigorous in-process validation to ensure compliance with ISO 2768 and customer-specific geometric tolerance standards. Tool wear compensation and breakage detection sensors are standard, providing real-time monitoring and enhancing process reliability.

The following table outlines typical achievable tolerances and compatible materials for our ATC-powered CNC router systems:

| Material Category | Examples | Typical Tolerance (± mm) | Max Dimension (mm) | Surface Finish (Ra µm) |

|———————–|——————————|—————————|——————–|————————-|

| Engineering Plastics | ABS, POM, PC, Nylon, PEEK | 0.01 – 0.03 | 1200 x 800 x 200 | 1.6 – 3.2 |

| Aluminum Alloys | 6061, 7075, 2024 | 0.01 – 0.02 | 1000 x 600 x 150 | 0.8 – 1.6 |

| Soft Metals | Brass, Copper, Zinc Alloys | 0.02 – 0.05 | 800 x 500 x 100 | 1.6 – 3.2 |

| Wood & Composites | MDF, Plywood, HDF, GFRP | 0.03 – 0.05 | 1500 x 1000 x 80 | 3.2 – 6.3 |

| Foams & Modeling | Urethane, EPS, PVC Foam | 0.05 – 0.10 | 2000 x 1000 x 100 | 6.3 – 12.5 |

Shenzhen Honyo Prototype’s ATC-integrated CNC routers combine speed, accuracy, and automation to meet the demands of modern precision manufacturing. Whether producing high-detail prototypes or tight-tolerance end-use parts, our systems ensure repeatability, material flexibility, and operational efficiency across diverse applications.

From CAD to Part: The Process

CNC Router Automatic Tool Changer: Production Process Workflow

At Shenzhen Honyo Prototype, our CNC router production process for parts requiring Automatic Tool Changers (ATC) is rigorously structured to ensure precision, efficiency, and manufacturability from initial concept to final component. This workflow leverages integrated digital systems to minimize lead times while maximizing part quality, specifically optimized for ATC-equipped routers which enable complex, multi-operation machining within a single setup.

The process initiates with the AI-Powered Quoting System. Upon receipt of a client’s CAD model (STEP, IGES, or native formats), our proprietary AI platform instantly analyzes geometry, material requirements, and specified tolerances. It cross-references this data against our extensive database of machine capabilities, material stock availability, and historical production metrics. Crucially for ATC workflows, the AI assesses potential toolpath complexity, estimating the number of tool changes required and identifying if the design inherently benefits from ATC functionality for operations like pocketing, profiling, engraving, or drilling with diverse cutters. This generates a highly accurate, data-driven quote within minutes, including estimated cycle times reflecting ATC utilization, providing immediate clarity on cost and feasibility.

Following client approval, the design enters the Critical DFM (Design for Manufacturability) Review. Our engineering team conducts a detailed analysis focused explicitly on ATC router constraints. This involves verifying tool accessibility for all features, ensuring sufficient clearance for the ATC magazine and tool carousel movement, and validating that the sequence of operations logically utilizes the available tool stations. We scrutinize hole depths versus tool lengths, check for potential collisions during tool changes, and confirm that the design allows for efficient toolpath strategies that minimize unnecessary tool swaps. Material suitability for the intended router cutters and spindle speeds is also confirmed. Any design conflicts identified—such as undercuts unreachable with standard tooling or features requiring more tools than the ATC capacity—prompt immediate client consultation for resolution before programming commences.

Once DFM sign-off is achieved, Production Execution begins. The approved CAD model is imported into our CAM software. Programmers generate optimized toolpaths, meticulously assigning specific tools (end mills, V-bits, drills, etc.) to the ATC slots and defining the precise sequence of operations and tool changes. The program includes robust safety checks for the ATC cycle. Material is loaded, the machine is calibrated, and the ATC magazine is populated with the specified tools. During machining, the router executes the program; upon reaching a tool change command, the spindle retracts to a safe position, the ATC arm indexes to the next tool station, retrieves the new tool, inserts it into the spindle, and ejects the used tool back into its slot—all within seconds, as defined by the machine specifications below. Real-time monitoring ensures process stability, and final parts undergo stringent dimensional and surface finish inspection against the original CAD model and client specifications.

This integrated workflow—from AI-driven quoting through ATC-focused DFM to controlled production execution—ensures Honyo Prototype delivers complex CNC router parts with ATC efficiency, minimizing manual intervention risks and maximizing throughput for our clients.

Typical CNC Router ATC System Specifications at Honyo Prototype

| Parameter | Value Range | Significance for Production |

| :—————– | :———————— | :———————————————- |

| Tool Capacity | 8 to 12 Stations | Dictates maximum operations per setup |

| Tool Change Time | 2.5 to 4.0 Seconds | Directly impacts overall cycle time efficiency |

| Tool Holding | ISO 30 / HSK 63 | Ensures rigidity and precision for fine features|

| Max Tool Diameter | 20mm to 25mm (Ø) | Influences DFM checks for pocket accessibility |

| Max Tool Length | 120mm to 150mm (L) | Critical for deep cavity machining validation |

| Positioning Accuracy| ±0.01mm | Guarantees repeatability across multiple tools |

Start Your Project

Start Your High-Precision CNC Project with Honyo Prototype

At Shenzhen Honyo Prototype, we specialize in delivering precision CNC machining solutions tailored to your engineering and prototyping needs. Our advanced CNC router systems equipped with automatic tool changers (ATC) ensure faster production cycles, improved accuracy, and consistent part quality—critical advantages for industries ranging from aerospace and automotive to consumer electronics and medical devices.

When you choose Honyo Prototype, you gain access to state-of-the-art manufacturing infrastructure backed by over a decade of expertise in rapid prototyping and low-to-mid volume production. Our ATC-enabled CNC routers minimize downtime by automatically switching tools during operation, allowing complex multi-operation machining—such as milling, drilling, tapping, and contouring—in a single setup. This capability not only enhances efficiency but also maintains tight tolerances down to ±0.005 mm, ensuring your components meet the highest standards of precision and repeatability.

We understand that every project has unique requirements. That’s why our engineering team works closely with clients from the initial design phase through final production. Whether you’re developing a prototype for validation or preparing for small-batch manufacturing, our CNC machining services support a wide range of materials, including aluminum alloys, stainless steel, brass, plastics (such as PEEK, ABS, and polycarbonate), and engineered composites.

Our facility in Shenzhen is ISO 9001-certified, and we employ real-time quality monitoring throughout the machining process. From 3-axis to 5-axis CNC routing with ATC integration, we offer scalable solutions that reduce lead times without compromising on quality.

Below are key specifications of our CNC router ATC systems:

| Specification | Detail |

|—————————–|———————————————|

| Machine Type | CNC Router with Automatic Tool Changer |

| Axis Configuration | 3-axis, 4-axis, and 5-axis options |

| Spindle Speed | Up to 24,000 RPM |

| Tool Magazine Capacity | 8, 12, or 20 tools (configurable) |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Supported Materials | Metals, Plastics, Composites, Wood, Foam |

| Maximum Work Envelope | 1300 x 2500 mm (custom sizes available) |

| Control System | Siemens, Syntec, or Mach3 (customer choice) |

| Lead Time (Typical) | 3–7 days for prototypes; scalable for volume |

Starting your project with Honyo Prototype is simple. We accept STEP, IGES, SolidWorks, and DXF file formats and provide free Design for Manufacturability (DFM) feedback to optimize your components for performance and cost-efficiency.

Ready to bring your design to life? Contact Susan Leo, our dedicated project coordinator, to discuss your machining requirements, request a quote, or schedule a technical consultation.

Susan Leo

Email: info@hy-proto.com

Shenzhen Honyo Prototype Co., Ltd.

Precision CNC Machining | Rapid Prototyping | ATC-Enabled Manufacturing Solutions

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.