Contents

Manufacturing Insight: Cnc Tap

Manufacturing Insight: CNC Tapping Capabilities at Honyo Prototype

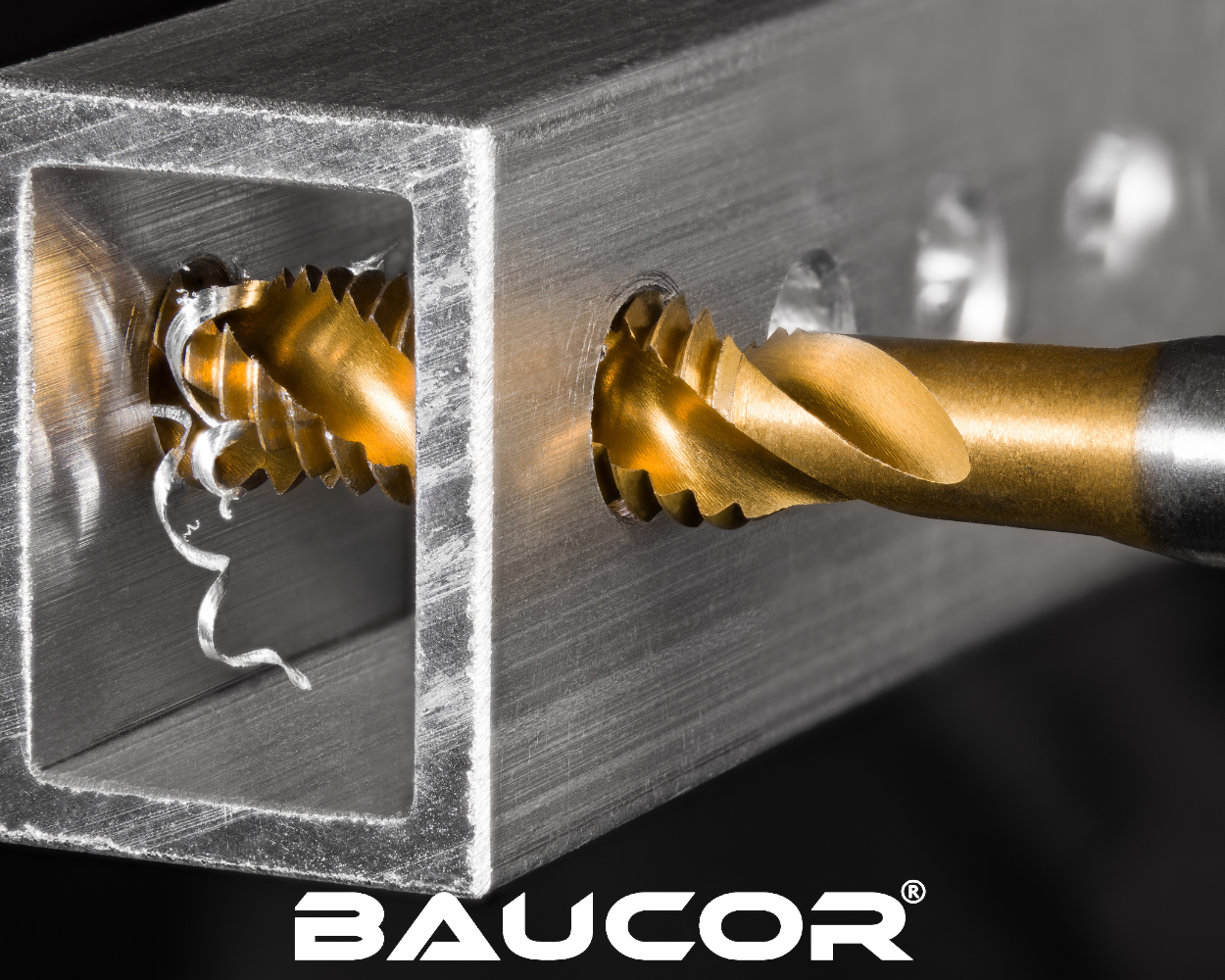

CNC tapping represents a critical precision process within subtractive manufacturing, transforming pre-drilled holes into functional threaded features with exacting dimensional control. At Shenzhen Honyo Prototype, we execute this operation using advanced multi-axis CNC machining centers integrated with rigid tapping cycles and high-speed spindle synchronization. Unlike manual or basic tapping methods, our CNC-driven approach eliminates human variability, ensuring consistent thread form, pitch accuracy, and depth control essential for assembly integrity in aerospace, medical, and industrial applications. The process demands meticulous parameter optimization—factoring in material hardness, thread engagement length, coolant delivery, and tool geometry—to prevent common failure modes like chip jamming, tap breakage, or thread stripping.

Our facility leverages real-time process monitoring and adaptive control systems to maintain thread quality across diverse material substrates. We specialize in challenging applications including blind holes in hardened steels, fine-pitch threads in thin-walled aluminum components, and multi-start threads requiring sub-0.02mm positional repeatability. Honyo’s engineering team develops custom tapping protocols for each project, selecting specialized tooling (spiral point, spiral flute, or forming taps) and optimizing feed rates/spindle speeds to maximize tool life while meeting ASME B1.1 or ISO 965 thread class standards. In-process metrology verifies pitch diameter and flank angles using coordinate measuring machines (CMM) and optical comparators, ensuring compliance before part release.

The following table outlines our core CNC tapping specifications and material capabilities:

| Parameter | Capability Range | Tolerance/Standard |

|————————-|————————————–|————————|

| Thread Sizes | M1.6 to M24 (Metric) | ISO 965 Class 6G |

| | #0-80 to 1″-14 (Imperial) | ASME B1.1 Class 2B |

| Materials | Aluminum Alloys (6061, 7075) | All aerospace grades |

| | Stainless Steel (303, 304, 17-4PH) | Including hardened to 45 HRC |

| | Titanium (Gr2, Gr5), Brass, Plastics | Post-machining anodize available |

| Depth-to-Diameter Ratio | Up to 3:1 (standard) | 4:1 achievable with specialized tooling |

| Surface Finish | Ra 0.8 µm (typical) | Custom finishes per drawing |

| Production Capacity | Prototypes to 500-unit batches | 72-hour rapid turnaround standard |

Honyo Prototype differentiates through integrated process validation. Our engineers conduct pre-production tap testing on sacrificial material blocks matching the production lot, validating chip evacuation and thread integrity before full-scale machining. This eliminates costly rework and accelerates time-to-assembly for clients. Additionally, we employ high-pressure coolant systems and through-spindle lubrication to enhance chip clearance in deep holes—particularly critical for gummy materials like 316 stainless or titanium. For mission-critical components, we provide full traceability including tool wear logs and first-article inspection reports compliant with AS9102.

By combining rigorous process control with material science expertise, Honyo ensures threaded features meet functional requirements on the first iteration. This reduces scrap risk and supports seamless integration into downstream assembly processes, reflecting our commitment to delivering precision prototypes and low-volume production parts that perform to specification. Partner with us to mitigate tapping challenges in your next precision component project.

Technical Capabilities

CNC Tapping Capabilities at Shenzhen Honyo Prototype

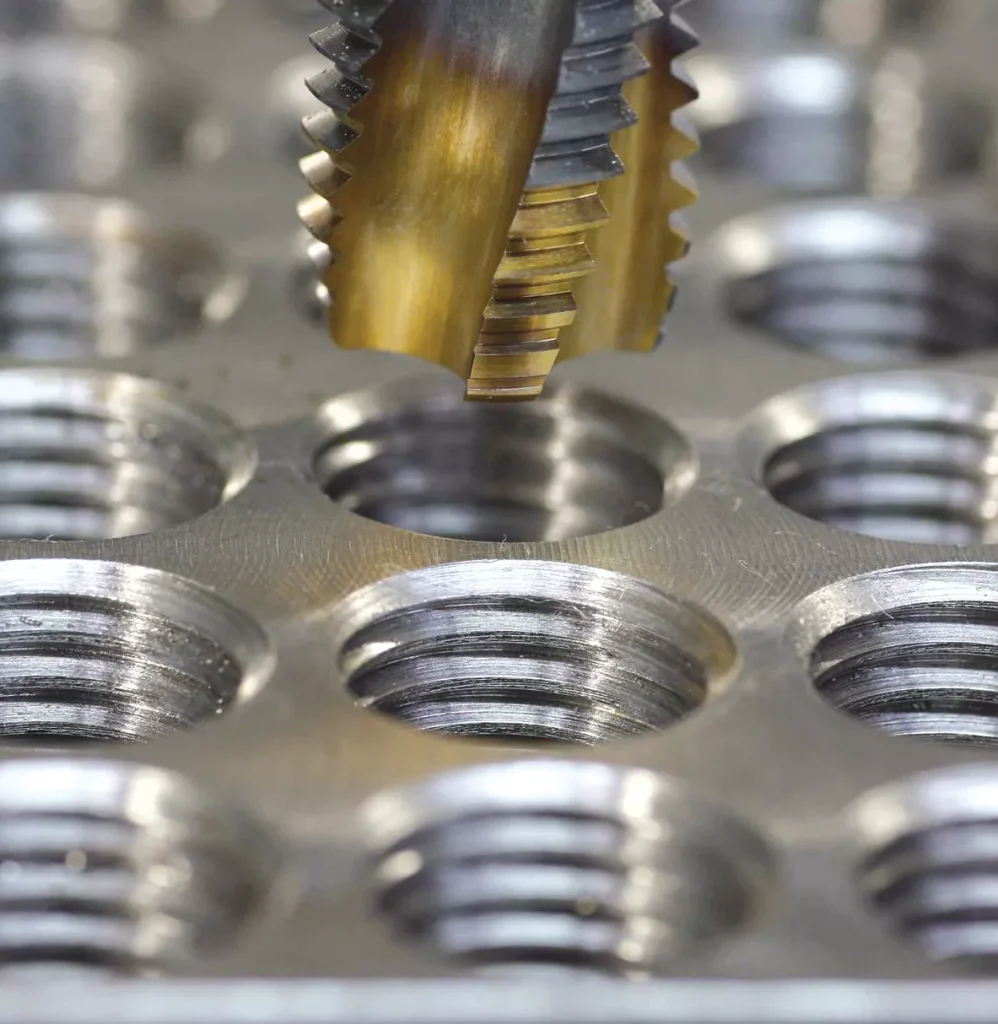

At Shenzhen Honyo Prototype, our CNC tapping services are integrated within advanced 3-axis, 4-axis, and 5-axis milling platforms, enabling precision thread creation in complex geometries and hard-to-reach areas. Leveraging high-rigidity machining centers with synchronized spindle controls, we ensure accurate tap alignment, minimized tool deflection, and consistent thread quality across both prototyping and low-volume production runs. Our CNC tapping processes support through-holes, blind holes, and variable thread depths with full control over feed rate, spindle speed, and chip evacuation—critical for maintaining integrity in delicate or high-strength materials.

Our technical expertise spans multiple industry standards, including ISO, ASME, and DIN, allowing us to produce internal threads ranging from M2 to M24 (metric) and #2-56 to 1/2″-13 (imperial). Threads can be machined to Class 4H, 5H, 6H, and 7H tolerances, depending on application requirements. We utilize both rigid tapping and high-performance tapping cycles with floating tool holders where necessary to accommodate slight misalignments and ensure thread accuracy in challenging setups. Additionally, our 5-axis capabilities enable compound-angle tapping, eliminating the need for secondary fixturing and reducing cumulative alignment errors.

Tight-tolerance threading is a core strength, with standard thread positional accuracy maintained within ±0.05 mm and achievable precision down to ±0.02 mm using in-process probing and post-machining CMM validation. This level of control is essential for aerospace, medical, and automation components where thread fit and assembly reliability are mission-critical.

We support a broad range of materials, from free-machining metals to abrasion-resistant alloys and engineering plastics. Each material group is processed with optimized cutting parameters and coolant strategies to prevent galling, tap breakage, and poor thread finish.

Below is an overview of our standard tapping capabilities and material compatibility:

| Parameter | Specification |

|——————————-|————————————————————-|

| Axis Configuration | 3-axis, 4-axis, 5-axis CNC Milling; CNC Turning with Y-axis |

| Thread Standards | ISO Metric, Unified National (UN/UNF), NPT, BSPP, Custom |

| Thread Sizes | M2–M24; #2-56 to 1/2″-13 |

| Thread Classes | 4H, 5H, 6H, 7H (customizable) |

| Positional Tolerance | ±0.05 mm (standard); ±0.02 mm (tight-tolerance achievable) |

| Depth Tolerance (Blind Holes) | ±0.1 mm |

| Surface Finish (Thread) | Ra 1.6–3.2 µm (standard); Ra ≤1.0 µm (precision finish) |

| Tooling Types | High-speed steel (HSS), Cobalt, Carbide; Spiral point/flute |

| Coolant Delivery | Through-spindle high-pressure coolant; Mist cooling option |

| Material Category | Compatible Materials |

|———————–|————————————————————————————–|

| Aluminum Alloys | 6061, 7075, 2024, 5052, 6082 |

| Steel Alloys | Mild Steel, 4140, 4340, 1018, 1045 |

| Stainless Steel | 303, 304, 316, 17-4PH, 440C |

| Tool Steels | D2, A2, H13 |

| Titanium Alloys | Grade 2, Grade 5 (Ti-6Al-4V) |

| Plastics | PEEK, Delrin (POM), Nylon, Polycarbonate, Acrylic |

All tapped features undergo first-article inspection, with thread fit verified using go/no-go gauges, optical comparators, and coordinate measuring machines. At Honyo Prototype, we combine advanced CNC infrastructure with rigorous process control to deliver reliable, repeatable tapping solutions tailored to your engineering demands.

From CAD to Part: The Process

CNC Tapping Production Workflow: From CAD to Precision Part

At Shenzhen Honyo Prototype, our CNC tapping process integrates advanced digital tools with rigorous engineering oversight to transform CAD designs into high-integrity threaded features. This workflow ensures dimensional accuracy, thread quality, and material integrity while optimizing throughput. The sequence begins upon receipt of a validated CAD model, where our proprietary AI quoting engine initiates automated feature recognition. This system algorithmically identifies all tapped holes, extracting critical parameters such as thread type, nominal diameter, depth, pitch, and location. Concurrently, it assesses geometric complexities like blind-hole bottoming, proximity to edges, or intersecting features that could impact tool access or chip evacuation. The AI engine then generates a preliminary quote within minutes, factoring in material grade, thread class requirements, and machine time estimates derived from historical process data.

Following client approval, the design enters the mandatory Design for Manufacturability (DFM) phase. Our senior manufacturing engineers conduct a detailed review focused specifically on tap feasibility. Key considerations include verifying adequate clearance for tap entry and withdrawal, confirming minimum wall thickness around tapped features to prevent blowout, and evaluating material machinability for optimal tap selection. We rigorously check depth-to-diameter ratios to mitigate tap breakage risks, especially in challenging materials like stainless steel or titanium. Any design conflicts—such as insufficient drill depth for full thread engagement or inadequate chip clearance—are flagged with actionable recommendations. This collaborative DFM stage typically resolves 95% of potential production issues before machining commences, directly enhancing yield rates and reducing lead times.

Production execution leverages Honyo’s precision CNC machining centers equipped with rigid tapping cycles and high-pressure through-spindle coolant. Prior to tapping, holes undergo precise pre-drilling with optimized chamfering to ensure clean thread formation. Tap selection is material-specific: cobalt HSS taps for aluminum and plastics, solid carbide for hardened steels, and specialized coatings like TiN for abrasive alloys. Critical process parameters are strictly controlled as shown in the table below:

| Parameter | Standard Range | Critical Considerations |

|——————–|———————-|————————————————–|

| Spindle Synchronization | 1:1 (Rigid Tapping) | Eliminates thread pitch errors; mandatory for ISO 6H/7H tolerances |

| Coolant Pressure | 50-100 bar | Ensures chip evacuation; prevents galling in sticky materials |

| Feed Rate | Pitch × RPM | Matched exactly to tap lead; deviations cause thread stripping |

| Tap Depth Overshoot| 1.5× Pitch | Guarantees full thread form at hole bottom |

Throughout production, in-process inspections validate thread pitch diameter using calibrated thread plug gauges, while surface roughness is verified to ≤Ra 1.6µm. Final first-article inspection includes cross-sectional thread analysis for critical aerospace or medical components. This integrated AI-DFM-production framework achieves >98% first-pass yield for tapped features, minimizing rework and ensuring threads meet ASME B1.1 or ISO 261/262 standards. By embedding engineering rigor at every phase, Honyo Prototype delivers threaded components that perform reliably in high-stress assemblies, directly supporting our clients’ product integrity goals.

Start Your Project

Start Your CNC Tap Project with Precision and Confidence

At Shenzhen Honyo Prototype, we understand that precision threading is a critical component in high-performance manufacturing. Whether you’re developing aerospace components, medical devices, or industrial machinery, the integrity of threaded features directly impacts functionality, safety, and reliability. Our CNC tapping services are engineered to deliver accurate, repeatable, and clean internal threads across a wide range of materials—from aluminum and stainless steel to titanium and engineering plastics.

CNC tapping is more than just creating threads; it’s about ensuring dimensional accuracy, thread strength, and surface finish consistency. With advanced CNC machining centers and real-time tool monitoring systems, Honyo Prototype maintains tight tolerances down to ±0.005 mm. Our team employs both rigid and floating tap holders to accommodate varying depth-to-diameter ratios and material hardness, minimizing the risk of tap breakage and thread inaccuracies.

We support a full spectrum of thread standards, including metric (M3, M4, M6, etc.), unified national coarse (UNC), and unified national fine (UNF), as well as custom thread forms upon request. Our process integrates seamless CAD/CAM workflows, allowing us to translate your design intent into precise physical results with minimal lead time.

To ensure optimal outcomes, our engineers conduct a comprehensive design for manufacturability (DFM) review before production begins. This includes evaluating tap drill sizes, hole depth, exit clearance, and material suitability—helping you avoid common pitfalls such as chip evacuation issues or thread stripping.

Below is an overview of our standard CNC tapping capabilities:

| Parameter | Specification |

|—————————-|——————————————–|

| Minimum Tap Size | M1.6 (metric), #2-56 (imperial) |

| Maximum Tap Size | M24 (metric), 1/2″-13 UNC (imperial) |

| Tolerance Range | ±0.005 mm to ±0.02 mm |

| Thread Standards Supported | ISO, DIN, JIS, ANSI, ASME, custom profiles |

| Materials | Aluminum, Steel, Stainless Steel, Titanium, Brass, Plastics |

| Surface Finish | Ra 0.8 µm to Ra 3.2 µm (adjustable) |

| Lead Time | 3–7 days (standard), expedited options available |

All tapping operations are followed by rigorous quality inspection using coordinate measuring machines (CMM), thread gauges, and optical comparators. We provide full traceability and inspection reports upon request, ensuring compliance with ISO 9001 standards and your specific quality requirements.

Starting your project with Honyo Prototype is simple. Share your part drawings or 3D models, and our engineering team will respond with a detailed quotation and DFM feedback within 12 hours.

For immediate assistance, contact Susan Leo at info@hy-proto.com. With over a decade of experience in precision prototyping and low-volume production, Susan serves as your dedicated project liaison, guiding you from initial inquiry to final delivery with transparency and technical excellence.

At Honyo Prototype, we don’t just manufacture parts—we build partnerships based on reliability, speed, and engineering integrity. Let us help you achieve flawless threading in every component. Reach out today and experience the Honyo difference.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.