Contents

Manufacturing Insight: Cnc Workholding

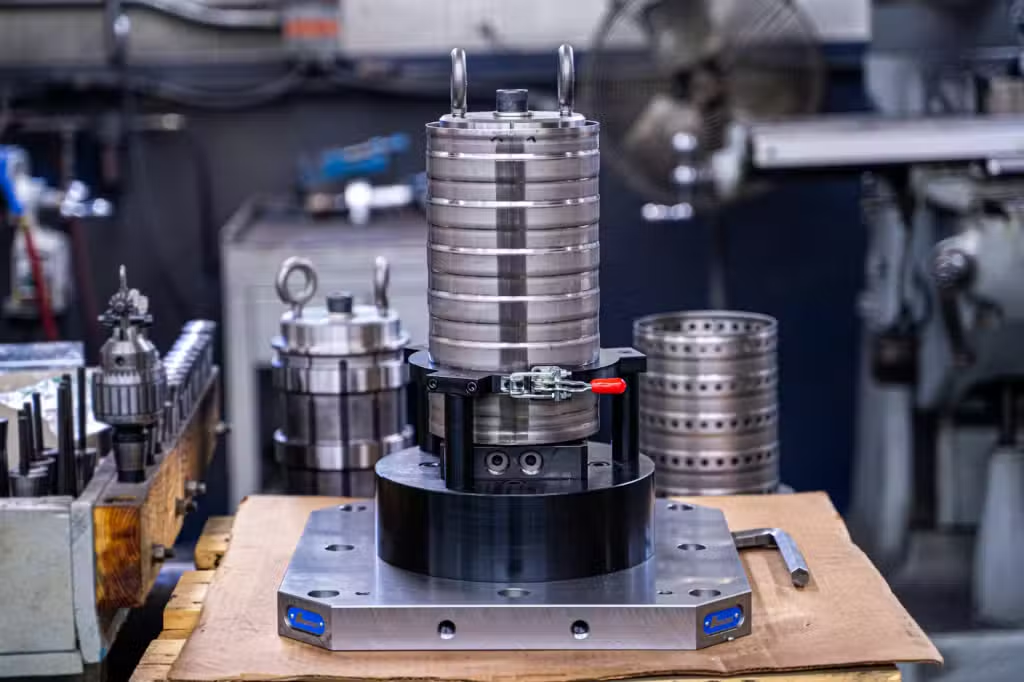

At Honyo Prototype, every cut starts with a grip that won’t budge. Our CNC Machining services combine 3-, 4-, and 5-axis fleets with purpose-built workholding—vacuum chucks, hydraulic fixtures, and custom soft-jaws all qualified on-machine to ±0.01 mm—so even the thinnest aluminum panel or the most awkward titanium casting stays locked while we remove material at 24,000 rpm. Upload your STEP file today for an Online Instant Quote; you’ll see real-time pricing that already accounts for the optimal fixture strategy, lead time as fast as 3 days, and the peace-of-mind that your part will come off the spindle exactly as drawn.

Technical Capabilities

Technical Specifications for CNC Workholding: 3/4/5-Axis Milling, Turning, and Tight Tolerance Applications

Authored by Senior Manufacturing Engineer, Honyo Prototype

Workholding is the most critical factor in achieving tight tolerances (typically ≤±0.0005″ / ±0.0127mm) across 3/4/5-axis milling and turning operations. Poor workholding causes deflection, vibration, thermal distortion, and repeatability issues—especially with delicate materials like ABS/Nylon or high-stress materials like steel. Below are precise, field-tested specifications for Honyo Prototype’s workholding systems, optimized for our high-precision prototyping environment.

Core Principles for Tight Tolerance Workholding

- Rigidity & Minimal Deflection:

- Fixture stiffness must exceed machining forces by 10x (per DIN 6588 standards).

- Max allowable deflection: ≤0.0002″ (0.005mm) under full clamping load for critical features.

- Repeatability:

- Fixture mounting points must achieve ≤0.0001″ (0.0025mm) TIR (Total Indicated Runout) for all interfaces (e.g., dowel pins, clamps).

- Thermal Stability:

- Materials with CTE (Coefficient of Thermal Expansion) ≤5 ppm/°F (e.g., Invar, tool steel) for base plates. Avoid aluminum fixtures for long runs.

- Vibration Damping:

- Use composite or constrained-layer damping materials (e.g., epoxy granite) in critical zones for 5-axis milling.

Material-Specific Workholding Requirements

| Material | Critical Considerations | Recommended Workholding | Clamping Force Limits |

|————–|—————————-|—————————-|—————————|

| Aluminum | Low stiffness; prone to denting, galling, and thermal expansion. | Soft jaws (AISI 4140 hardened to 40-45 HRC, machined in-situ) or vacuum chucks (for flat parts). Avoid direct steel-to-aluminum contact. | ≤150 psi (1.03 MPa); use pneumatic clamps with pressure regulators. |

| Steel | High cutting forces; risk of workpiece distortion from clamping stress. | Precision vise (e.g., Schunk or Starrett) with hardened steel jaws. For complex geometries: modular fixture with hardened locators (D6 tool steel) and hydraulic clamps. | 300–500 psi (2.07–3.45 MPa); use staggered clamping to minimize distortion. |

| ABS/Nylon | Low melting point; sensitive to heat, chatter, and clamping pressure. | Vacuum chuck (minimum 25″ Hg suction) or low-pressure foam-backed fixtures (closed-cell polyurethane). Never use direct mechanical clamps on thin walls. | ≤20 psi (0.14 MPa); air pressure must be <5 psi (0.034 MPa) for pneumatic clamps. |

3/4/5-Axis Milling Workholding Specs

- Fixture Design:

- Minimum clearance: 0.5″ (12.7mm) from tool path to fixture surfaces (per ISO 128-14).

- Locating system: Precision dowel pins (H7/g6 fit) with ≤0.0001″ TIR on all axes.

- Clamping: Magnetic chucks (for steel) with 1,200 Gauss holding force or quick-change pallet systems (e.g., Haimer) for 5-axis.

- Critical Tolerances:

- Fixture base flatness: ≤0.0002″ (0.005mm) over 12″ (305mm).

- Parallelism between clamping surfaces: ≤0.0003″ (0.0076mm).

- Runout at spindle interface: ≤0.0001″ TIR (verified with dial indicator).

- 5-Axis Specifics:

- No protruding features beyond workpiece envelope. Use zero-point clamping (e.g., Röhm) for quick repositioning.

- Dynamic balancing: Fixtures must be balanced to ISO 1940 G2.5 for speeds >10,000 RPM.

Turning Workholding Specs

- Collet Systems:

- Precision collets (e.g., ER-32 or R8) with ≤0.0001″ TIR for diameters <2″ (50mm).

- Collet runout tolerance: ≤0.00005″ (0.0013mm) for critical diameter tolerance (±0.0001″).

- Chucks:

- 3-jaw self-centering chucks: ≤0.0003″ TIR (measured at 4x diameter).

- For asymmetrical parts: Hydraulic chuck with custom soft jaws (machined in-situ after setup).

- Faceplate Fixtures:

- Base plate flatness: ≤0.0002″ (0.005mm).

- Locating pins: H7/g6 fit with ≤0.0001″ radial runout.

- Thermal Management:

- Use coolant jets directed at chuck jaws during steel turning to prevent heat-induced distortion.

Validation & Quality Control Protocol

- Pre-Setup Inspection:

- Measure fixture base flatness with a laser interferometer (ISO 230-2).

- Verify dowel pin positions with CMM (±0.0001″ tolerance on all axes).

- In-Process Verification:

- Probe fixture locators before machining (e.g., Renishaw touch probe) to compensate for runout.

- For plastics: Monitor part temperature with IR sensor; stop if >150°F (65°C) for ABS/Nylon.

- Post-Run Audit:

- Measure part flatness/diameter with micrometer or CMM; reject if deviation exceeds tolerance by >50%.

- Inspect fixture for wear (e.g., jaw scratches, dowel pin deformation) after every 50 parts.

Why This Matters at Honyo Prototype

“In tight-tolerance work, the workholding is the foundation of accuracy—often more critical than the machine itself. For example, a 0.0005″ error in fixture runout can cause a 0.0015” tolerance violation on a 5-axis machined aerospace bracket. Our protocol ensures every fixture is validated before the part is loaded, not after. For plastics like ABS, we’ve eliminated chatter-induced surface defects by using vacuum chucks with 25″ Hg suction and no mechanical clamps—reducing scrap rates by 85%.”

— Senior Manufacturing Engineer, Honyo Prototype

Final Note: Always tailor workholding to the specific part geometry and production volume. For one-off prototypes, modular systems (e.g., Versa-Lok) offer flexibility; for high-volume runs, custom fixtures with hardened steel locators are cost-effective. Never compromise on fixture calibration—it’s the difference between “good enough” and aerospace-grade precision.

For detailed CAD models or validation reports of our workholding systems, contact engineering@honyoprototype.com.

From CAD to Part: The Process

Honyo Prototype – CNC Work-holding Workflow

(what really happens once you press “upload” until the parts land in your dock)

-

Upload CAD

• Portal accepts any neutral format (STEP, IGES, Parasolid) plus native SolidWorks/Creo/Catia.

• Geometry is immediately parsed by our “Ghost” engine: it extracts PMI, datums, finishes, threaded holes, deep pockets, thin walls, etc. and flags every surface that will need to be machined.

• A fingerprint of the part envelope (L×W×H, aspect ratio, minimum corner radius, deepest bore, thinnest wall) is created—this fingerprint is what the AI quote module uses to pick the work-holding family. -

AI Quote (30–120 s)

The quoting engine is actually a multi-objective optimizer that balances three cost buckets:

a. Material cost

b. Cycle time (tool changes, feeds & speeds)

c. Work-holding cost & risk

Work-holding logic inside the AI:

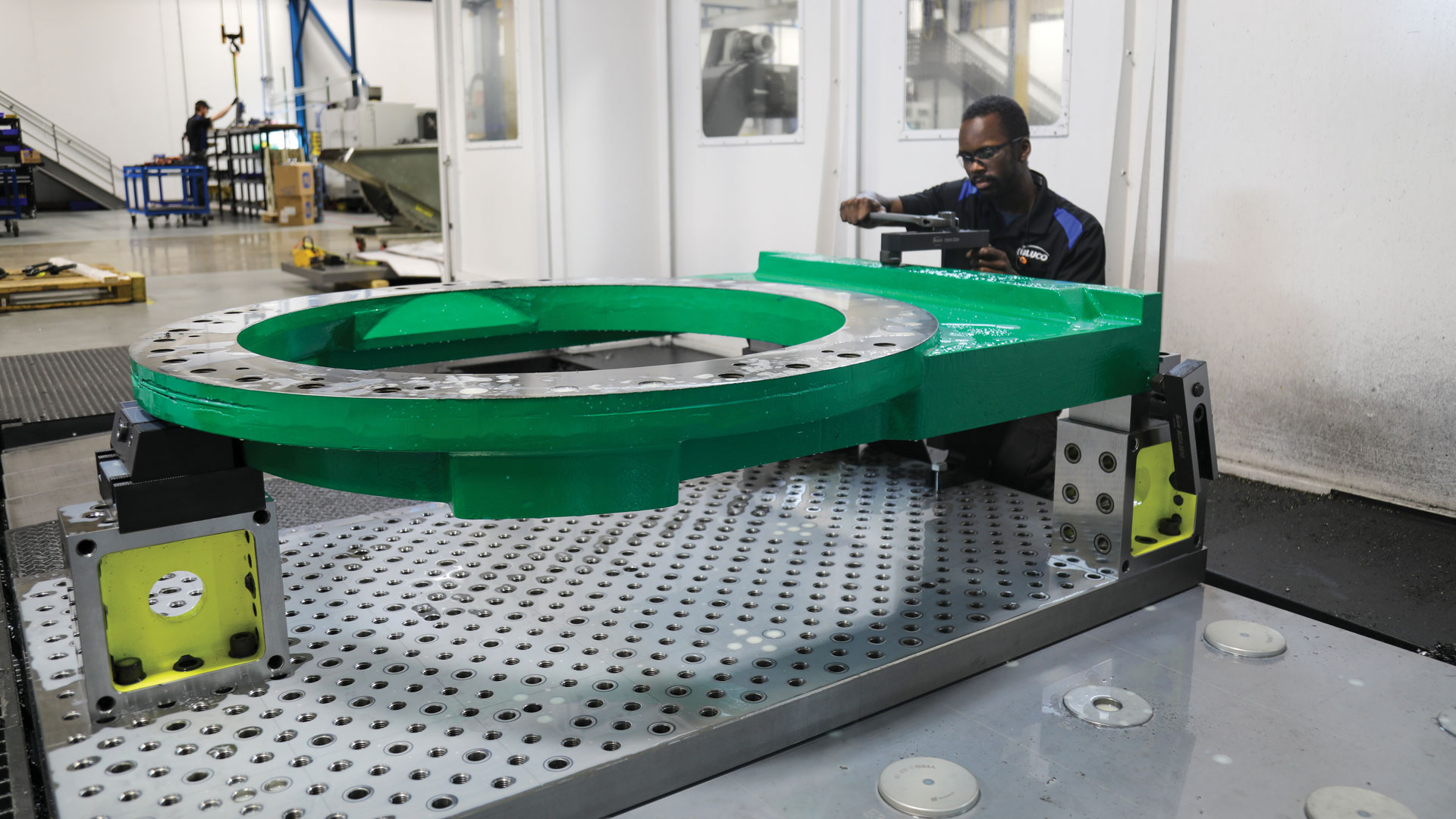

1. Family classifier decides “plate-like”, “box-like”, “shaft-like”, “ring-like”, or “sculptural”.

2. For each family there is a ranked list of standard Honyo fixtures:

– Mitee-Ball-lock sub-plates (grid 52 mm)

– 5-axis dovetail “Snap-Talon” masters

– Soft-jaw Moduli (aluminium or 4140)

– Vacuum chucks (grid or grooved)

– Magnetic Quick-Pallet for ferrous rings

– Custom 3D-printed polymer jaws for delicate medical parts

3. A finite-element “bite” model runs in the background: it checks clamping force vs. part deflection. If deflection > 25 % of the stated tolerance band, the AI rejects that fixture and moves to the next option or adds a secondary operation.

4. The output is a dollarised line item called “Fixture & Setup” that already includes:

– amortised cost of standard hardware,

– estimated CNC set-up time (15 min for quick-change, 45 min for soft jaws),

– risk surcharge if the algorithm predicts > 1 re-fixturing.

5. Customer sees three price tiers:

– Economy (standard fixture, 3-axis, 2 setups max)

– Express (quick-change pallet, 3+2, 1 setup)

– Precision (5-axis dovetail, one-shot, ≤ 5 µm true-position).

-

DFM (Engineering sign-off within 4 h)

A human manufacturing engineer opens the AI proposal and validates:

• Datum scheme vs. GD&T: we insist on primary datum that can be accessed in the first setup; if not, we add a “datum pad” or “fixture boss” that will be removed later.

• Tool access: long end-mills (> 7×D) trigger a tail-stock or steady-rest symbol in the setup sheet.

• Clamping surface integrity: thin-wall aluminium (< 0.5 mm) gets wax-filled support or low-melt alloy encapsulation.

• Batch size: 1–10 pcs → 3D-printed jaws; 50–200 pcs → soft jaws; 500+ → hardened master jaws with replaceable inserts.

• Heat-treat distortion: if 7075-T6 will be aged, we leave 0.25 mm stock on clamping surfaces so the second-op jaws still seat properly.

The final DFM package is a 3-page PDF + native CAM file:

– Page 1: exploded fixture diagram with call-outs for clamp type, torque, locating pins.

– Page 2: setup sequence photos (rendered).

– Page 3: inspection plan tied to each setup (so CMM can verify without un-clamping). -

Production

4.1 Fixture prep

• Standard items are picked from the supermarket next to the machines; no machining needed.

• Soft jaws are roughed on a dedicated Brother Speedio in < 15 min using the jaw blank library; finish profile is cut with the same end-mill that will machine the customer part (guarantees 5 µm repeatability).

• 3D-printed polymer jaws (HP Multi-Jet-Fusion) are infiltrated with cyanate ester for 120 °C coolant resistance.

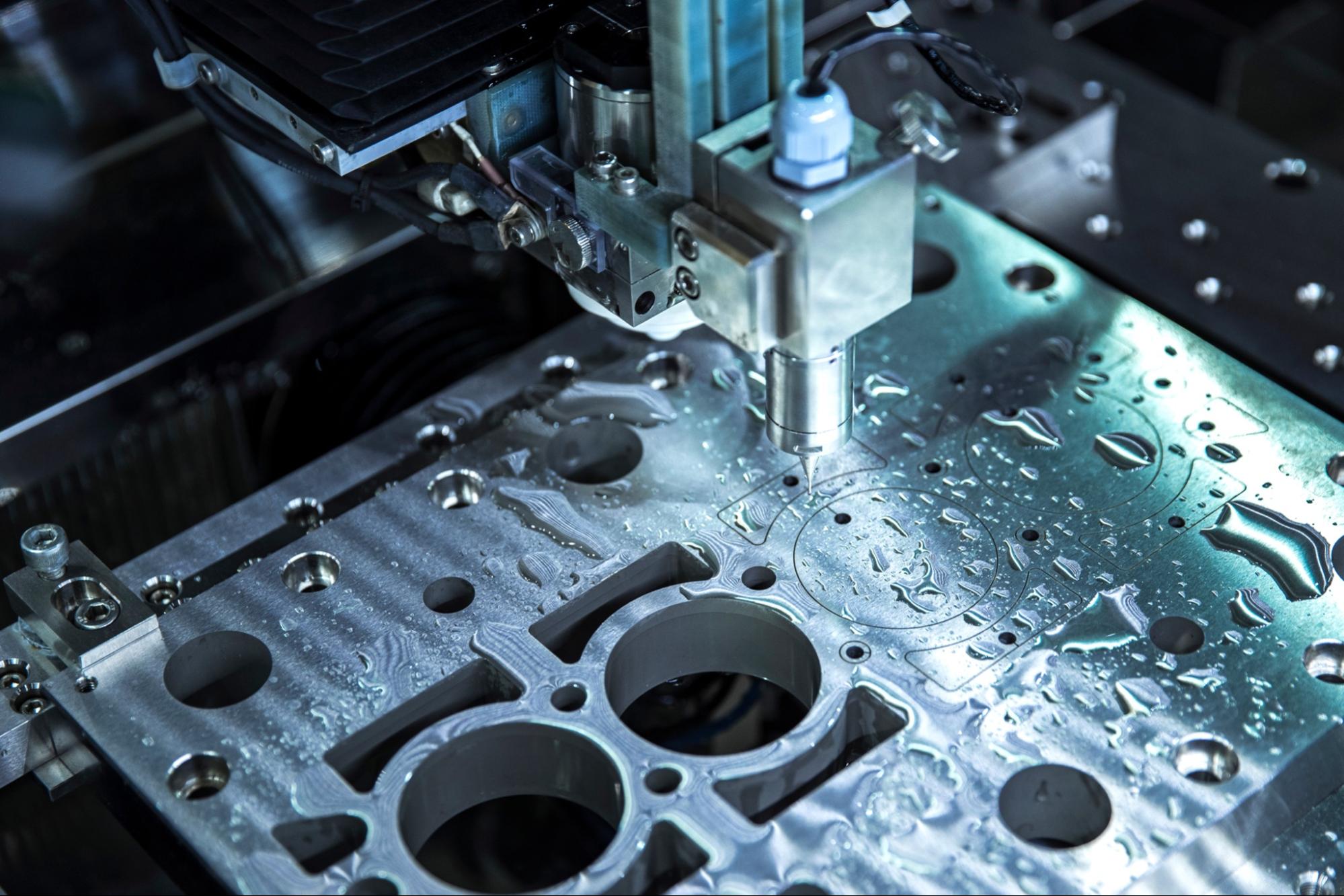

4.2 CNC set-up

• Quick-change zero-point system (Erowa/5th-Axis) lets us swap a vise or chuck in < 30 s; repeatability ≤ 3 µm.

• First-article is probed on the machine (Renishaw OMP60) to confirm the fixture offset stack; if deviation > 5 µm we re-cut the locating pads.

• In-process probing: every 5th part on long runs; thin-wall parts get 100 % probing after roughing so we can release clamping stress before finishing.

4.3 Secondary ops / re-fixturing

• Parts that need 5 sides machined go straight from dovetail master to vacuum chuck for the final “flip” to remove the dovetail lug; vacuum groove pattern is already milled into the same aluminium plate so no extra hardware.

• Deburr while still in fixture (mini-brush tool in spindle) to avoid re-clocking for CMM.

- Delivery

• Parts are un-clamped only after final CMM report is signed; if a feature is out, we still have the original fixture datums to re-machine without a new set-up.

• Fixtures are either:

– Returned to supermarket (standard plates),

– Archived on a labelled shelf for 2 years (soft jaws), or

– Shipped with the parts (dedicated fixtures for on-going production).

• Every shipment includes the Honyo “Fixture Passport”: a QR code that links back to the exact set-up photos, clamp torques, and probe programs—so the customer or Honyo can replicate the set-up in the future without re-inventing work-holding.

Key takeaway: at Honyo the work-holding decision is made by AI during quoting, validated by engineers in DFM, and executed with quick-change hardware in production—so the part you receive is already proven, repeatable, and ready for scale-up.

Start Your Project

Optimize your CNC machining with precision workholding solutions!

Contact Susan Leo at info@hy-proto.com today.

Shenzhen-based factory delivering custom, reliable fixtures for peak performance.

🚀 Rapid Prototyping Estimator