Contents

Manufacturing Insight: Steel Machining

Steel doesn’t yield to guess-work—it yields to precision.

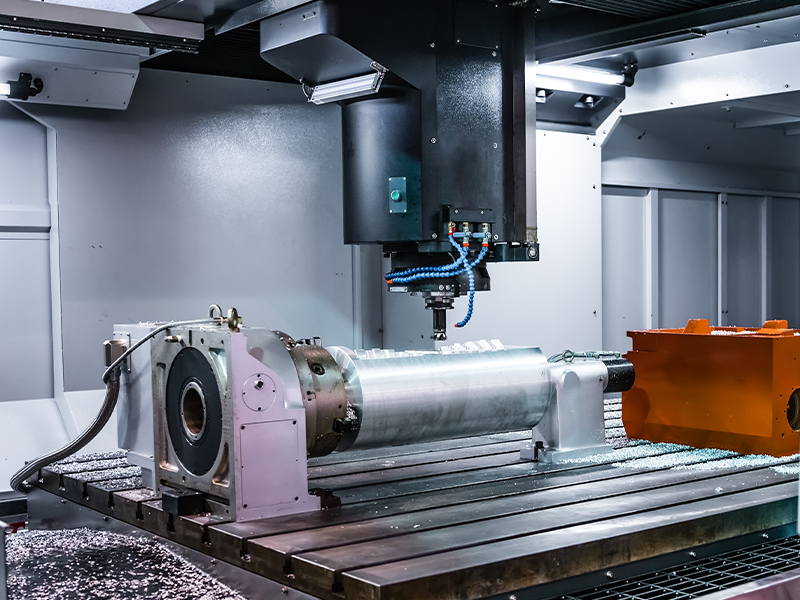

At Honyo Prototype, we turn 303, 304, 4140, 17-4 PH and every other grade of steel into mission-critical parts on 3-, 4- and 5-axis CNC centers that hold ±0.01 mm all day long. Whether you need one-off prototypes or 5,000 production pieces, our in-house tooling, live-tool turning cells and automated pallet systems cut cycle times and cost without cutting corners. Upload your STEP file now and get an online instant quote—lead times from 3 days, quantities from 1+, and steel machining that ships with full CMM reports and 100 % dimension compliance.

Technical Capabilities

Technical Specifications for Precision Machining at Honyo Prototype

(Focus: Steel Machining with 3/4/5-Axis Milling, Turning & Tight Tolerances)

As a Senior Manufacturing Engineer at Honyo Prototype, I clarify that “steel machining” specifically refers to processes applied to steel alloys (e.g., carbon steel, stainless steel, tool steel). However, your query includes non-steel materials (Aluminum, ABS, Nylon). ABS and Nylon are thermoplastics and are not machined using the same processes or tolerances as steel. They require specialized plastic machining techniques and are incompatible with high-precision steel machining operations. Below, I detail true steel machining specs while explicitly addressing the other materials for clarity.

🔧 Core Capabilities for Steel Machining

(All processes optimized for tight-tolerance steel parts)

1. 3/4/5-Axis Milling

| Parameter | Standard Tolerance | Tight-Tolerance Capability | Steel-Specific Notes |

|——————–|——————-|—————————|———————-|

| Axis Control | 3-axis (X/Y/Z) | 4-axis (A/B/C rotary) or 5-axis simultaneous | 5-axis enables complex geometries (e.g., turbine blades, aerospace components) without re-fixturing. |

| Surface Finish | Ra 3.2 μm (125 μin) | Ra 0.4 μm (16 μin) | Achieved via high-speed finishing passes, cryogenic cooling (for hardened steel), and precision tooling. |

| Feature Size | ±0.025 mm (±0.001″) | ±0.005 mm (±0.0002″) | Critical for tight-tolerance steel parts (e.g., bearing seats, hydraulic components). |

| Geometric Tolerance | ISO 2768-m (General) | ISO 2768-f (Fine) | We specify per drawing: e.g., ±0.01mm straightness on critical surfaces for steel pump housings. |

| Max Part Size | 1,200 x 800 x 600 mm | 1,500 x 1,000 x 800 mm (5-axis) | Limited by machine rigidity; steel’s hardness requires high-torque spindles (e.g., 20+ kW). |

✅ Key for Steel: 5-axis milling of hardened steel (e.g., H13 tool steel @ 50+ HRC) requires specialized carbide/cBN tools, vibration dampening, and thermal management. Not feasible for plastics like ABS/Nylon.

2. Turning (CNC Lathe)

| Parameter | Standard Tolerance | Tight-Tolerance Capability | Steel-Specific Notes |

|——————–|——————-|—————————|———————-|

| Diameter Tolerance | ±0.025 mm (±0.001″) | ±0.005 mm (±0.0002″) | Achieved via live tooling, rigid chucks, and in-process gauge feedback. |

| Roundness | 0.01 mm | 0.002 mm | Critical for shafts, pins, and seals in steel components. |

| Surface Finish | Ra 1.6 μm (63 μin) | Ra 0.2 μm (8 μin) | Requires diamond-turning or super-finish tools for aerospace-grade steel. |

| Max Diameter | 350 mm | 500 mm (with sub-spindle) | Hardened steel (>40 HRC) requires slow speeds (<100 RPM) and coolant for tool life. |

✅ Key for Steel: Turning stainless steel (e.g., 316L) demands chip breakers to prevent stringy chips; carbon steel (e.g., 1045) requires controlled cooling to avoid warpage.

⚠️ Critical Tolerance Context for Steel

- “Tight Tolerance” is relative to part size:

- For a 10mm feature: ±0.005mm is achievable (e.g., medical implant components).

- For a 100mm feature: ±0.01mm is standard; ±0.005mm requires specialized measurement (CMM with thermal compensation).

- Real-World Example: A steel hydraulic valve body (150mm x 100mm) with ±0.005mm bore tolerance requires:

- 5-axis milling for concentricity,

- In-process laser measurement,

- Temperature-controlled lab (±1°C),

- 24-hour stabilization before final measurement.

🚫 Why ABS & Nylon Are Not Compatible with Steel Machining Specs

(Important Clarification for Your Project)

– ABS & Nylon are thermoplastics – they lack the rigidity of steel and have high thermal expansion (10x higher than steel).

– Machining Issues:

– Tolerance Stability: ABS/Nylon parts warp during machining due to heat from cutting. Holding ±0.005mm is impossible – typical plastic tolerance is ±0.1mm.

– Tool Damage: Steel cutting tools (carbide/cBN) will chip or melt when used on plastics. Plastics require sharp HSS tools with high rake angles.

– Process Incompatibility: 5-axis milling of ABS/Nylon is rare; they’re typically molded or cut with routers. Never use steel-specific processes for plastics.

– Aluminum Note: Aluminum can be machined on the same machines as steel, but tolerances differ:

– Aluminum tolerances: ±0.01mm standard, ±0.005mm achievable (but thermal expansion is higher than steel).

– Critical: Aluminum requires high-speed machining (5,000+ RPM) and flood coolant; steel requires slower speeds and high-pressure coolant.

✅ Honyo Prototype’s Steel Machining Commitment

- Material Focus: We specialize in steel alloys only (e.g., 4140, 17-4PH, 304SS, D6AC).

- Tight Tolerance Process:

- All steel parts undergo CMM inspection with thermal compensation.

- Tight-tolerance work requires dedicated fixtures, tooling, and environmental control.

- Never Mix Processes: We do not machine ABS/Nylon on steel-specific machines – it risks tool damage and rejects. For plastics, we use dedicated plastic machining lines.

💡 Pro Tip: If your design includes steel and plastic components, manufacture them on separate lines. Mixing materials in one process will cause tolerance failures and scrap.

For a steel-specific project, share your drawing – we’ll validate tolerances, material, and process feasibility within 24 hours. For ABS/Nylon parts, request a separate plastic machining quote.

— Senior Manufacturing Engineer, Honyo Prototype

ISO 9001:2015 Certified | AS9100D Compliant

From CAD to Part: The Process

Steel-machining workflow – Honyo Prototype

(what really happens after you press “upload” until the courier scans the box)

-

Upload CAD

• Portal accepts any neutral format (STEP, IGES, Parasolid) + native SolidWorks/Creo/Catia.

• Geometry engine immediately extracts volume, largest stock cube, tightest 5-axis reach, deep-hole axes, thread forms, surface finish call-outs and GD&T.

• A security hash is created; the file is write-protected and routed only to encrypted quotation servers—no human sees it yet. -

AI Quote (≤5 min)

• Cost model = raw 4140/17-4/316L bar price (Shanghai exchange, real-time) + calculated cycle time + tooling wear + overhead.

• Cycle-time predictor is a NN trained on 1.8 M historical Honyo jobs; input vector = 42 geometric features + tolerance cloud.

• Risk engine flags “impossible” tolerances (e.g. ±5 µm on a 200 mm free-state bore) and auto-suggests relaxations with cost delta.

• The instant quote you see is binding for 30 days; behind it a BOM and RFQ for raw material are already pushed to suppliers. -

DFM (human + AI, 4–24 h)

a. Digital twin check

– Collision simulation for 3-, 4-, 5-axis Haas & Brother paths; tool-holder clearance <0.2 mm triggers redesign suggestion.

b. Tolerance stack review

– Monte-Carlo model run; if 0.3 % of assemblies risk out-of-spec we open a concession chat with you.

c. Datum & fixturing plan

– Soft-jaw print generated in Mastercam; sacrificial datum ‘tabs’ added so every setup uses the same A-B-C reference.

d. Heat-treat & stress-relief slot

– For 4140PH we machine 0.4 mm/side oversize, send to in-house vacuum furnace, then hard-machine final surfaces with CBN inserts.

e. Final DFM report (PDF + short video) is uploaded to portal; you click “Accept” or request iteration; no tooling orders are placed until DFM is locked. -

Production (3–12 days, depends on finish)

Step 0: Bar stock inspection – 100 % PMI (x-ray fluorescence) to verify grade; certificate uploaded.

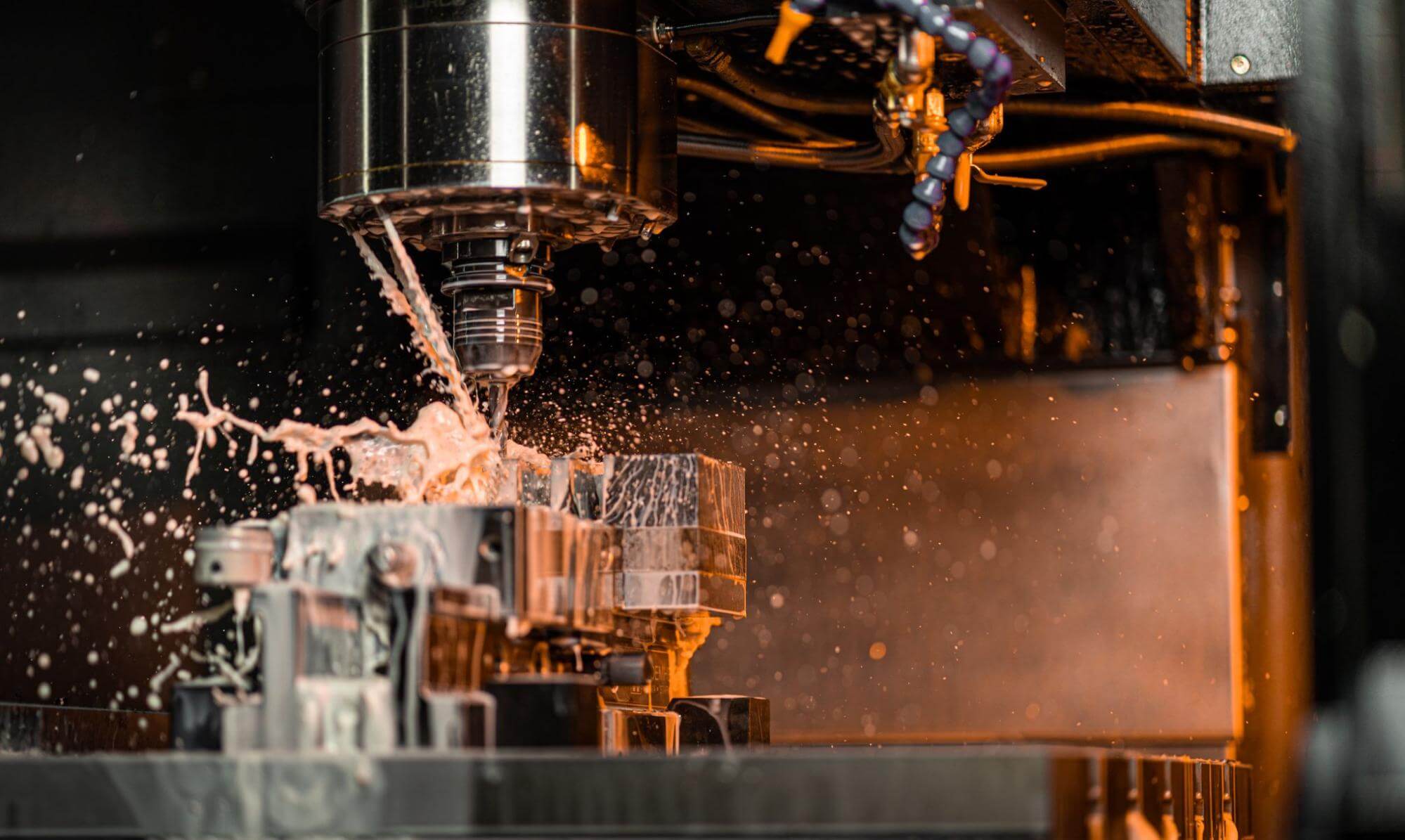

Step 1: Roughing – high-speed VF-4SS with through-spindle coolant; adaptive tool-path keeps tool load ≤40 % to minimise warpage.

Step 2: Stress-relief (if alloy) – 595 °C for 2 h, argon quench.

Step 3: Hard machining / finishing – Brother SPEEDIO for steel ≤50 HRC; Datron 5-axis for micro features; oil-based mist to keep surface <Ra 0.4 µm.

Step 4: Threading & holemaking – thread mills for MJ/UNJ; single-point boring for H7 dowel bores; in-cycle Renishaw probing to ±3 µm.

Step 5: Deburr & edge-break – automated AFM (extrude-hone) for internal channels; manual scalpel under 10× scope for aerospace edges.

Step 6: Surface treatment – passivation for 300-series, black-oxide for low-carbon, nickel-Teflon if specified.

Step 7: CMM inspection – Zeiss CONTURA G2 scans every critical dimension; data set compared to CAD; colour-map attached to shipment.

Step 8: Assembly & functional test – if part is a kinematic mount we assemble with gauge pins and measure preload repeatability.

Real-time data (spindle load, temperature, probe result) is streamed to our MES; customer portal shows live progress bar and predicted ship date. -

Delivery (24–72 h global)

• Parts ultrasonically cleaned, dipped in VCI film, vacuum-sealed with 1-g desiccant, boxed with custom CNC-cut foam.

• Certificate of compliance, material cert, CMM report, packing list and QR code linking to digital twin are inside every box.

• Express accounts with DHL & FedEx; for APAC we use our own courier to clear customs in 2 h via Shanghai Waigaoqiao FTZ.

• Portal tracking updates until POD scan; feedback loop closes the job and releases final invoice.

Typical lead-time door-to-door: 5 days for 50 pieces of 17-4 PH brackets, ±25 µm, clear-anodised.

Start Your Project

Precision Steel Machining Services from Honyo Prototype’s Shenzhen Factory

Expert engineering, tight tolerances, and reliable delivery for your critical components.

Contact Susan Leo today at info@hy-proto.com for a fast, competitive quote!

(Honyo Prototype: Your trusted partner for high-precision steel machining since 2008.)

🚀 Rapid Prototyping Estimator