Contents

Manufacturing Insight: Metal Fabrication Laser Cutting

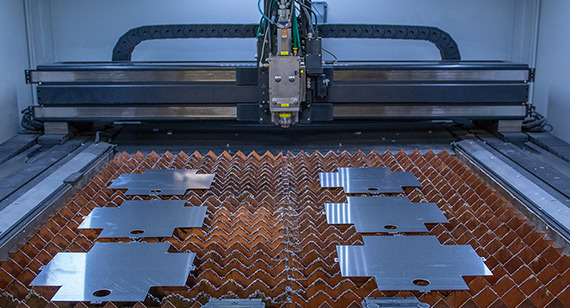

Precision starts with a pulse of light. At Honyo Prototype, our 6 kW fiber-laser cells turn your sheet-metal concepts into clean, dross-free parts in hours, not weeks. From 0.1 mm shims to 20 mm mild-steel brackets, we hold ±0.05 mm true-position tolerances so your next assembly slides together without a second operation. Upload your .dxf, .step or .iges file today and you’ll see an online instant quote—material, lead-time and delivered cost—before your coffee cools. That’s instant pricing on real manufacturing capacity, not a marketing placeholder. Whether you need one-off prototypes or 5,000-part production runs, Honyo’s sheet-metal fabrication team lasers, forms, inserts and finishes under one ISO 9001 roof, ready to ship in as fast as 3 days.

Technical Capabilities

Important Clarification Before Proceeding

ABS and Nylon are NOT metals—they are thermoplastics. Metal fabrication exclusively deals with metallic materials (e.g., steel, aluminum, stainless steel, copper). Plastics like ABS and Nylon require separate processes (e.g., plastic-specific laser cutting, heat forming, or ultrasonic welding), as they cannot be bent or welded using standard metal fabrication techniques.

If you intended to discuss metal fabrication only:

– Focus on metals (e.g., steel, aluminum, stainless steel).

– ABS/Nylon should be excluded—they belong to plastic fabrication, which has entirely different technical specs.

If you need specs for both metals AND plastics:

– I’ll provide metal fabrication specs for steel/aluminum (as requested), plus a separate section for ABS/Nylon (as plastic-specific processes).

– Critical note: Mixing metals and plastics in the same fabrication process is impossible—e.g., you cannot weld ABS to steel, and laser cutting plastics requires different equipment than metals.

🛠️ I. Metal Fabrication Specifications (Steel & Aluminum Only)

Applicable to standard metal fabrication (e.g., Honyo Prototype’s core services). ABS/Nylon are excluded here—they are not metals.

🔪 1. Laser Cutting

- Laser Type: Fiber laser (1–6 kW for metals; CO2 lasers are obsolete for metals).

- Wavelength: 1.06–1.08 μm (optimized for metal absorption).

- Max Thickness:

| Material | Max Thickness (mm) | Typical Tolerance | Edge Quality |

|—————|———————|——————-|————–|

| Mild Steel | 25 mm | ±0.05–0.1 mm | Smooth, oxide-free with N₂ assist gas |

| Stainless Steel | 20 mm | ±0.05–0.1 mm | Minimal dross with N₂ |

| Aluminum | 15 mm | ±0.1 mm | Requires N₂ purge to avoid oxidation; rougher edge than steel | - Key Parameters:

- Power: 1–4 kW for thin sheets (<6 mm), 4–6 kW for thick sections.

- Assist Gas:

- Oxygen (O₂): For carbon steel (exothermic reaction speeds cutting).

- Nitrogen (N₂): For stainless steel/aluminum (prevents oxidation, creates clean edges).

- Cutting Speed: 1–10 m/min (depends on thickness/material; e.g., 3 mm steel at 15 m/min).

- Surface Finish: Ra 3.2–6.3 μm (typical for cut edges; post-processing like grinding may be needed for high-precision parts).

📐 2. Bending (Press Brake)

- Tonnage Requirements: Based on material thickness, length, and V-die width.

| Material | Thickness (mm) | Max Bend Length (m) | Tonnage (per meter) | Bend Radius (min.) |

|———-|—————-|———————|———————|——————-|

| Mild Steel | 2 | 3 | 15 tons | 0.8×thickness |

| Mild Steel | 10 | 3 | 150 tons | 2×thickness |

| Aluminum (6061) | 5 | 3 | 50 tons | 1.0×thickness | - Key Parameters:

- Bend Radius: Minimum radius = 0.5–1.0×material thickness (to avoid cracking).

- Angle Accuracy: ±0.5° (standard); ±0.2° with CNC precision.

- V-Die Width: Typically 8–10×material thickness (e.g., 10 mm thick steel → 80–100 mm V-die).

- Springback Compensation: Aluminum requires 2–5° more angle than target due to higher springback vs. steel.

- Surface Protection: Use rubber or plastic pads on dies to prevent scratches (critical for aesthetic parts).

🔥 3. Welding

- Common Processes:

| Process | Best For | Key Parameters | Typical Applications |

|———|——————-|———————————————–|———————-|

| MIG (GMAW) | Mild steel, stainless steel | Wire: ER70S-6 (steel), ER308L (stainless); Shielding: CO₂/Ar mix (80/20); Amperage: 150–300A | Structural frames, brackets |

| TIG (GTAW) | Aluminum, stainless steel | Tungsten: 2% Thoria; Shielding: 100% Ar; Amperage: 50–200A; Filler: ER4043 (Al), ER308L (SS) | Thin sheets, precision joints, aerospace |

| Spot Welding | Sheet metal (steel) | Electrode force: 2–5 kN; Current: 5–15 kA; Time: 0.1–0.5s | Automotive panels, enclosures | - Critical Specs for Aluminum:

- Preheat: Required for >3 mm thickness (100–150°C) to prevent cracking.

- Shielding Gas: 100% Argon (no oxygen).

- Wire Type: ER4043 or ER5356 (for structural integrity).

- Weld Quality Standards:

- ISO 5817 (for steel/stainless) or ISO 10042 (for aluminum).

- Typical defects to avoid: Porosity (max 1.5 mm diameter), cracks (any size), undercut (max 0.5 mm depth).

🧪 II. Plastic Fabrication Specs (ABS & Nylon Only)

These are NOT part of metal fabrication. ABS/Nylon require plastic-specific processes.

🔪 1. Laser Cutting

- Laser Type: CO₂ laser (10.6 μm wavelength).

- Max Thickness:

| Material | Max Thickness (mm) | Tolerance | Notes |

|———-|———————|———–|——-|

| ABS | 12 mm | ±0.1 mm | High smoke; requires extraction system |

| Nylon | 10 mm | ±0.1 mm | Melts easily; low laser power (20–50W) | - Key Parameters:

- Speed: 5–20 mm/s (ABS), 2–10 mm/s (Nylon).

- Fumes: ABS releases toxic hydrogen cyanide—mandatory fume extraction required. Nylon emits caprolactam (irritant).

- Edge Quality: Slightly melted edges; no post-processing needed for non-critical parts.

📐 2. Bending

- Process: Heat forming, NOT press brake bending (plastics deform under heat, not mechanical force).

- Method:

- Heat plastic to 100–150°C (ABS) or 180–220°C (Nylon) using infrared heaters or hot air guns.

- Bend over a mold; cool rapidly to set shape.

- Critical Specs:

- Minimum Bend Radius: 2–3×thickness (e.g., 3 mm ABS → min. 6–9 mm radius).

- Warpage Risk: High if cooling is uneven; requires clamping during cooling.

- No “Bend Allowance” Calculation: Unlike metals, plastic bending relies on thermal expansion.

🔥 3. Welding

- Process: Not arc welding! Plastic welding uses:

| Method | Best For | Key Parameters | Notes |

|—————–|———-|—————|——-|

| Ultrasonic Welding | ABS, Nylon | Frequency: 20–40 kHz; Amplitude: 25–100 μm; Energy: 50–500 J | Fast, clean joints; no filler |

| Hot Plate Welding | Large parts | Temperature: 180–250°C; Pressure: 0.5–2 MPa | Used for automotive parts |

| Solvent Welding | ABS only | Solvent: Acetone or MEK | Bonds via dissolution; weak for structural use | - Critical Specs:

- ABS: Melts at 105°C; solvent welding creates strong bonds.

- Nylon: Hygroscopic—must be dried before welding (80°C for 24h).

- Strength: Ultrasonic welds reach 80–90% of base material strength.

💡 Key Takeaways for Honyo Prototype

- Never mix metals and plastics in a single fabrication process.

- Example: You cannot laser-cut ABS and steel on the same machine without reconfiguration (CO₂ for plastics vs. fiber for metals).

- Material-Specific Rules:

- Aluminum requires nitrogen purge during laser cutting to avoid oxidation.

- ABS welding must exclude oxygen (use inert gas for TIG/MIG on metals only—plastics use ultrasonic/solvent).

- Design for Manufacturability (DFM):

- For metals: Avoid sharp internal corners (min. 1×thickness radius).

- For plastics: Avoid stress concentrations; use generous radii (>2×thickness).

✅ Recommendation: If your project includes both metals and plastics, treat them as separate components—fabricate metals via standard metal fab processes, and plastics via plastic-specific methods. Always specify material type clearly in engineering drawings (e.g., “Al 6061-T6” or “ABS Verbatim™”).

For further details, share your specific part geometry or application—Honyo Prototype can provide tailored process recommendations! 🛠️

From CAD to Part: The Process

Honyo Prototype – Metal Fabrication Laser Cutting Workflow

(what happens to your part from the moment you hit “upload” to the day it lands on your dock)

-

Upload CAD

• Portal accepts any mix of 2-D/3-D files: .step, .iges, .dxf, .dwg, .ai, etc.

• Instant geometry check: closed contours, self-intersections, duplicate entities removed.

• You pick material, thickness, qty, finish; the system stores your revision stack. -

AI Quote (≤30 s)

• Neural nest: part is auto-arrayed on standard sheets (steel, stainless, Al, Cu, Ti, brass).

• Real-time laser table library: 1–6 kW fiber, 1.5 × 3 m bed, ±0.05 mm positional accuracy, pierce & cut speed tables for every gauge.

• Cost engine adds: gas consumption, nozzle wear, machine amortization, secondary ops (deburring, tapping, countersink, bending), packing, freight.

• Dynamic pricing: material LME index + shop loading factor updated hourly → you see a live price and three delivery tiers (24 h, 72 h, 7-day).

• One-click accept locks material allocation on the floor. -

DFM (Design-for-Manufacture) – 30 min human review

• Kerf width & heat-affected zone simulation: we verify slot widths ≥ 0.8 × thickness, bridge ≥ 1 mm, hole ≥ 0.4 × thickness (or switch to punch start).

• Micro-tab placement: 0.2 mm tabs keep parts in skeleton for automated unload; tab location moved away from critical edges.

• Grain direction & cosmetic face call-out added if stainless #4 finish requested.

• Bend relief notches or etch lines inserted if part continues to press brake.

• Customer gets PDF report + 3-D snap-shot; approval required only if we changed geometry. -

Production

a. Nesting & NC generation

– SigmaNEST auto-nests on remnant tracker to hit 75 % sheet utilization; lead-in/out paths minimize piercing.

b. Material prep

– 2-D fiber laser (6 kW) with 15 bar N₂ for Al/Cu (oxide-free edge) or 1 bar O₂ for thick CS (better edge squareness).

– Automatic nozzle change & capacitive height control keep ±0.05 mm cut height.

c. In-process QC

– First-article contour scanned on-line with Keyence LJ-X8000 profiler; kerf vs. CAD deviation ≤ 0.05 mm.

– Statistical hole diameter checked every 10th part with Mitutoyo vision system.

d. Post-processing

– COMAU robot unloads skeleton, vibratory tumbling or planetary deburr for RA ≤ 1.6 µm edge.

– Tap, countersink, insert, or hardware insertion (PEM, Southco) done on Amada turret or Haeger press.

– Bending, welding, or plating follow in same job traveler to avoid re-handling. -

Delivery

• Parts ultrasonically cleaned, sealed in VCI film, boxed with silica gel; barcode & 2-D matrix link back to digital traveler.

• C of C, material certs (EN 10204 3.1), ROHS/REACH, and FAIR (AS9102 if aerospace) uploaded to customer portal before shipment.

• Global courier integration: you get a ship notice with photos of the packed crate and a predictive ETA; 24 h delivery available in EU/US/Asia metro zones.

Throughout the cycle every operation is time-stamped in our MES; you can log in and see the same Gantt chart we use on the shop floor. That’s the entire Honyo laser-cutting pipeline—upload to doorstep—without a single e-mail or phone call unless you want one.

Start Your Project

Precision Metal Fabrication Laser Cutting Services

From concept to reality—delivered with engineering excellence.

Honyo Prototype’s Shenzhen-based factory delivers high-precision laser cutting for prototypes and production, ensuring tight tolerances, rapid turnaround, and uncompromising quality.

Contact Susan Leo today:

📧 info@hy-proto.com

📍 Shenzhen, China

Let’s bring your designs to life—efficiently, accurately, and on time.

🚀 Rapid Prototyping Estimator