Contents

Manufacturing Insight: Nickel Plating Service

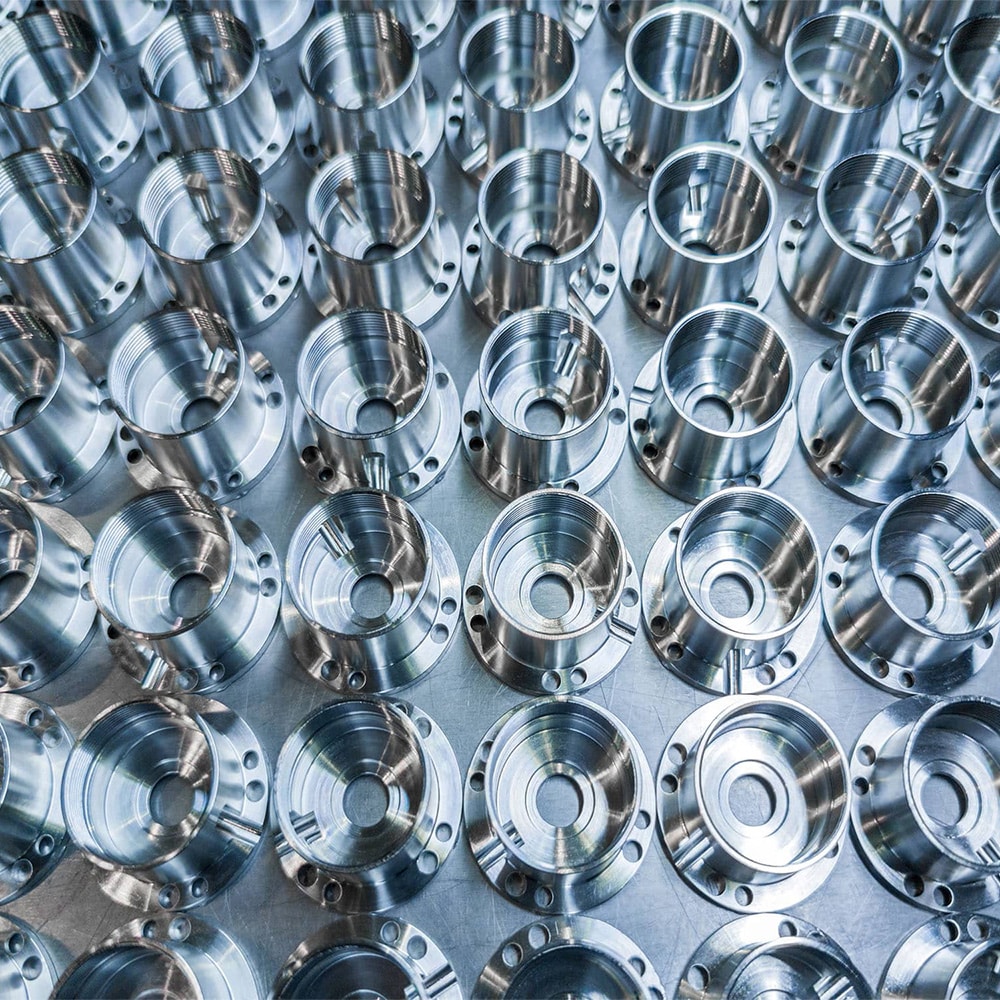

At Honyo Prototype, precision doesn’t stop when the last CNC cut is finished—it’s locked in with our in-house, RoHS-compliant nickel plating service. Whether you order one aerospace fitting or 10,000 electronic housings, your parts are machined on our 5-axis CNC centers, inspected to ±0.01 mm, and then transferred directly to the plating line. This single-flow process eliminates re-handling, cuts lead time by 30 %, and guarantees uniform adhesion on even the most complex geometries. Need numbers today? Upload your STEP file and get an online instant quote that shows CNC machining plus nickel plating cost and delivery in under 60 seconds.

Technical Capabilities

As a Senior Manufacturing Engineer at Honyo Prototype, I must address a critical misunderstanding in your query: Nickel plating is a surface finishing process and is NOT a machining service. It does not involve 3/4/5-axis milling, turning, or tight-tolerance machining. These are entirely separate manufacturing processes.

Let me clarify this immediately to prevent costly errors in your project planning:

❌ Core Misconception Clarified

- Machining (Milling/Turning):

- Involves removing material from raw stock using CNC machines (3/4/5-axis mills, lathes).

- Focus: Geometric accuracy, surface finish, dimensional tolerances (e.g., ±0.0005″ for tight-tolerance parts).

- Nickel Plating:

- A surface treatment process where a thin layer of nickel is electrochemically deposited onto a substrate.

- It does not alter the geometry of the part. It adds a uniform coating (typically 0.0001″–0.002″) to the existing machined surface.

- Plating does not “hold tight tolerances” for machining features. Instead, plating thickness must be accounted for after machining is complete.

✅ Correct Nickel Plating Technical Specs (as a Surface Finish Service)

At Honyo Prototype, our nickel plating service focuses on surface properties, not machining. Key specs include:

1. Plating Type & Thickness

- Electroless Nickel (EN):

- Thickness: 0.0001″–0.0025″ (typically 0.0005″ for corrosion resistance; 0.0015″–0.0025″ for wear resistance).

- Phosphorus content: 7–12% (for uniform deposition on complex geometries).

- Electrolytic Nickel:

- Thickness: 0.0001″–0.001″ (for decorative or functional use; e.g., bright nickel for aesthetics).

- Tolerance Impact: Plating adds material uniformly. For tight-tolerance parts, we recommend:

- Machining final dimensions to size before plating (with plating allowance factored in).

- Example: A 0.500″ hole machined to 0.4995″ will become ~0.5005″–0.502″ after 0.0005″–0.001″ plating.

2. Material-Specific Requirements

| Material | Plating Compatibility | Critical Pre-Treatment | Notes |

|———-|————————|————————-|——-|

| Steel | Excellent | Acid cleaning, activation | Standard for corrosion/wear resistance. |

| Aluminum | Requires special process | Zincating or tin-lead strike | Otherwise, poor adhesion. Not recommended for high-stress parts without proper prep. |

| ABS/Nylon (Plastics) | Only electroless nickel (EN) | Etching (chromic acid), catalyzation | Not for mechanical strength; used for EMI shielding or decorative finishes. |

3. Critical Quality Metrics

- Adhesion: ASTM B571 (tape test pass/fail).

- Porosity: ASTM B735 (salt spray test: 24–96 hrs for 0.0005″ EN).

- Hardness: 500–700 HV (for EN 7–12% P); 400–500 HV for electrolytic.

- Uniformity: ≤±10% thickness variation across complex geometries (verified by XRF or cross-sectioning).

4. What We Do NOT Do

- We do not perform milling, turning, or tolerance control for the base part.

- We do not “hold tight tolerances” for plating thickness. Thickness is controlled via process parameters (current density, bath chemistry), but it is not a precision machining tolerance.

🔧 How Machining & Plating Work Together at Honyo Prototype

If you need a part with both precision machining and nickel plating, here’s our workflow:

1. Machining Phase:

– Your part is precision-machined (3/4/5-axis milling, turning) to final dimensions with plating allowance.

– Example: For a 0.500″ diameter shaft to be plated with 0.0005″ EN, we machine to 0.4990″.

– Tight tolerances (e.g., ±0.0005″) are held during machining, not plating.

2. Plating Phase:

– After machining, the part is cleaned, activated, and plated.

– Plating adds a uniform layer, but does not correct machining errors (e.g., out-of-roundness, surface scratches).

⚠️ Critical Reminder: If your part requires tight tolerances after plating, you must specify:

– “Machined to [dimension] ±[tolerance] before plating, with plating allowance factored in.”

– We cannot plate a part to a “tight tolerance” – plating is a coating, not a machining process.

💡 Recommendation for Your Project

- If you need precision-machined parts with nickel plating:

- Specify machining tolerances for the base part (e.g., “±0.0005″ on critical dimensions”).

- Specify plating type/thickness (e.g., “Electroless Nickel, 0.0008″ ±0.0002″, ASTM B735 salt spray 72 hrs”).

- If you only need plating service, send us a finished machined part – we handle the surface finish.

We’d be happy to review your design and provide a tailored process plan. Please share your drawing with clear notes on:

– Machining requirements (dimensions, tolerances, surface finish)

– Plating specifications (type, thickness, testing standards)

– Material (e.g., 6061-T6 aluminum, 17-4 PH steel, ABS, Nylon 6/6)

This ensures your part meets functional requirements without costly rework. Let’s collaborate to get it right!

— Senior Manufacturing Engineer, Honyo Prototype

Precision Machining + Surface Finishing Solutions

From CAD to Part: The Process

Honyo Prototype – Nickel Plating Service Flow (end-to-end)

-

Upload CAD

• Portal accepts native SolidWorks, STEP, IGES, Parasolid, or STL.

• Geometry checker auto-repairs small gaps, duplicate faces, and reversed normals so the part can be meshed for plating simulation.

• If the file is a multi-body assembly the AI splits it into individual “plating tickets” and tags every surface that must be conductive. -

AI Quote (≤60 s)

• Surface-area engine: calculates true wetted area (including internal holes) rather than bounding-box area.

• Thickness selector: customer picks functional Ni (8 µm), heavy Ni (25 µm), or duplex Ni (8 + 16 µm).

• Rack vs. barrel decision tree: parts <M5 thread or <10 g go to barrel; parts with tight tolerance zones or cosmetic faces stay on titanium racks.

• Chemistry cost model: pulls current nickel sulphate, nickel chloride, and boric-acid spot prices from LME + Chinese chemical index and adds 3-day forecast buffer.

• Final quote shows piece price, rack surcharge, 48-h express option, and RoHS/REACH certificate line item. -

DFM (Design-for-Manufacturing) review – 4 h window

• Sharp-internal-corner flag: suggests ≥0.3 mm radius to prevent 3× thickness build-up and nodule formation.

• Aspect-ratio check: L/D > 3 holes are tagged for auxiliary anode or copper wire insert to keep 20 % thickness uniformity.

• Masking plan: AI proposes nitrile plugs for bores, high-temperature tape for grounding pads, and silicone caps for threaded studs; human plater validates.

• Tolerance stack-up: adds ±2 µm to plated dimension if part is going to a sliding fit; customer approves via one-click e-signature.

• Final traveller is released to MES with barcode; racking fixture STL is 3-D printed overnight if needed. -

Production – 3-day standard, 1-day express

a. Pre-treatment

– Vapor degrease in modified alcohol, 5 min ultrasonics, 2 % Oakite 61 alkaline soak, anodic etch in 10 % H₂SO₄ to get water-break-free surface.

b. Wood’s nickel strike

– 2 µm strike layer in 240 g/L NiCl₂ at 6 V for 90 s to guarantee adhesion on 6061-T6, 17-4 PH, or pure Cu.

c. Primary nickel

– Sulfamate bath 50 °C, 4 ASD, continuous carbon filtration; thickness measured in-line with Fischer XDL-φ, closed-loop PID controls delta-T within ±1 °C.

d. Post-plate options

– 0.2 µm hex-chrome-free topcoat for 96 h salt-spray, or 0.5 µm black nickel for optical baffles.

e. Final inspection

– X-ray fluorescence on five zones per drawing; Cpk ≥ 1.33 required.

– Adhesion tape test per ASTM B571; no peel-off allowed.

– 100 % visual under 6000 K LED, scratch-free to 40× magnification. -

Delivery

• Parts ultrasonically rinsed, hot-air dried at 60 °C, packed in sulfur-free VCI paper + vacuum bag, then foam-lined carton.

• C of C includes nickel thickness map, salt-spray certificate, and REACH SVHC statement.

• Track-and-trace link auto-emailed; typical door-to-door: Shenzhen to Silicon Valley 48 h via FedEx Priority, EU 72 h via DHL Express.

Entire loop: CAD upload to dispatched shipment can be as short as 72 h for express nickel plating orders.

Start Your Project

Get a Quote for Precision Nickel Plating – Contact Susan Leo at info@hy-proto.com | Honyo Prototype, Shenzhen Factory

Reliable, high-quality plating services backed by Shenzhen’s advanced manufacturing expertise. Reach out today to elevate your project!

🚀 Rapid Prototyping Estimator