Contents

Manufacturing Insight: Custom Aluminum Boxes

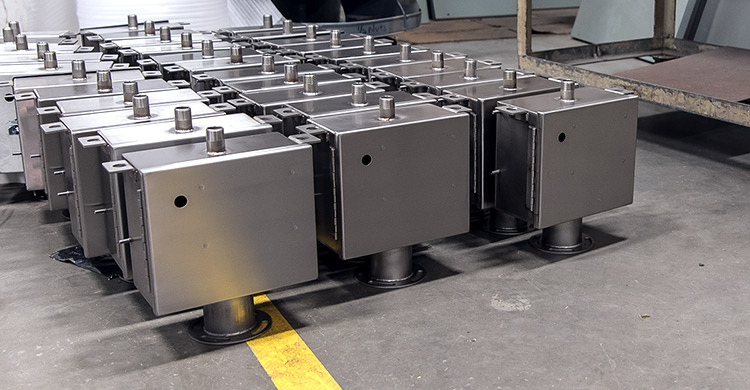

Manufacturing Insight: Precision Custom Aluminum Boxes via CNC Machining

Custom aluminum enclosures represent critical components across aerospace, medical, and industrial electronics sectors, where dimensional accuracy, thermal management, and structural integrity are non-negotiable. At Shenzhen Honyo Prototype, we leverage advanced CNC machining to transform aluminum billets into mission-critical boxes meeting stringent engineering specifications. Our process begins with material selection from certified aerospace-grade alloys, followed by multi-axis milling, turning, and finishing operations under ISO 9001-controlled conditions. Unlike sheet metal fabrication, CNC machining eliminates weld seams and secondary assembly risks, delivering monolithic enclosures with superior EMI shielding and hermetic sealing potential.

Honyo’s 5-axis milling centers achieve tolerances down to ±0.005 mm while maintaining surface finishes as fine as Ra 0.8 μm. This precision ensures seamless integration of PCBs, connectors, and thermal interfaces without post-machining adjustments. Our workflow integrates automated tool monitoring and in-process probing to correct thermal drift in real time, critical for maintaining flatness across large panels exceeding 500 mm. For complex geometries requiring internal channels or asymmetric mounting points, our CAM engineers optimize toolpaths to minimize chatter and maximize material removal rates—reducing lead times by 30% versus conventional methods.

Material versatility defines our capability stack. We routinely machine 6061-T6, 7075-T73, and custom anodizable alloys, tailoring heat treatment to balance machinability with end-use strength requirements. Secondary operations including precision tapping, PEM insert installation, and laser engraving are executed in-house, eliminating supply chain dependencies. Every enclosure undergoes CMM validation against 3D CAD models, with full traceability from raw material certs to final inspection reports.

Key technical parameters for our aluminum box production are summarized below:

| Parameter | Capability Range | Standard Tolerance |

|————————-|————————————–|——————–|

| Material Grades | 6061-T6, 7075-T73, 2024, 5052 | ASTM B221/B241 |

| Max Work Envelope | 1200 x 800 x 600 mm | – |

| Dimensional Tolerance | ±0.005 mm (critical features) | ±0.025 mm (standard)|

| Surface Finish | Ra 0.8 μm (milled), Ra 0.4 μm (polished) | MIL-A-8625 Class 3 |

| Lead Time | 7–15 days (prototypes to 50 units) | Varies by complexity|

Beyond precision, we solve real-world production challenges. For example, our vibration-dampening fixture design prevents thin-wall distortion during machining, while proprietary coolant strategies eliminate micro-cracks in high-strength 7075 alloys. Clients receive engineering support from DFM analysis through to first-article inspection, ensuring designs transition smoothly from prototype to volume production. With 12 years of aerospace and medical device experience, Honyo delivers not just components, but validated solutions that meet IPC-6012 and AS9100 compliance demands. Partner with us to transform your aluminum enclosure requirements into field-proven hardware with uncompromised reliability.

Technical Capabilities

Technical Capabilities: Precision CNC Machining for Custom Aluminum Boxes

Shenzhen Honyo Prototype specializes in high-precision CNC machining for custom aluminum enclosures, delivering robust, dimensionally accurate, and functionally optimized boxes for industrial, medical, and electronic applications. Our advanced 3-axis, 4-axis, and 5-axis milling capabilities, combined with precision CNC turning, enable the production of complex geometries with tight tolerances and superior surface finishes. Each custom aluminum box is manufactured to meet stringent engineering requirements, ensuring compatibility with demanding assembly and operational environments.

Our 3-axis CNC milling systems are ideal for producing standard box designs with flat surfaces, through-holes, and simple pocketing. These machines deliver high repeatability and efficiency for high-volume or prototype runs. For more complex features such as compound angles, undercuts, and multi-sided machining, we utilize 4-axis and 5-axis CNC centers. These systems allow for simultaneous multi-directional tool access, reducing setup changes and improving geometric accuracy. This capability is particularly beneficial for enclosures requiring integrated mounting bosses, flanges, or intricate cutouts on multiple faces.

CNC turning complements our milling services, especially for aluminum boxes with cylindrical features, threaded inserts, or coaxial alignment requirements. Components such as end caps, shaft mounts, or hybrid housings benefit from our turn-mill hybrid processes, ensuring concentricity and precise diameter control.

Tight tolerance machining is a core strength at Honyo Prototype. We consistently achieve tolerances down to ±0.005 mm on critical dimensions, with geometric tolerances controlled per ISO 2768 and customer-specific GD&T callouts. Our in-process inspection protocols, including CMM verification and optical measurement, ensure compliance throughout production.

We primarily machine aerospace- and industrial-grade aluminum alloys, selected for their strength-to-weight ratio, thermal conductivity, and corrosion resistance. Post-machining treatments such as anodizing, bead blasting, and powder coating are available to enhance durability and aesthetics.

The following table outlines our standard machining capabilities and material options for custom aluminum boxes:

| Parameter | Specification |

|——————————-|————————————————|

| Milling Axes | 3-axis, 4-axis, 5-axis |

| Turning | CNC turning with live tooling (optional) |

| Maximum Work Envelope (mm) | 1200 × 800 × 600 |

| Typical Tolerance (milling) | ±0.01 mm (standard), ±0.005 mm (tight) |

| Surface Finish (Ra) | 0.8–3.2 µm (as machined), finer with polishing |

| Positional Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Material | Common Grades | Key Properties |

|——————–|———————–|———————————————|

| Aluminum Alloy | 6061-T6, 7075-T6 | High strength, good machinability |

| Aerospace Aluminum | 2024-T3 | Excellent fatigue resistance |

| Medical-Grade | 6061-T6 (certified) | Biocompatible, corrosion-resistant |

All custom aluminum box projects benefit from our integrated design-for-manufacturability (DFM) review, ensuring optimal tool access, wall thickness, and feature feasibility. At Shenzhen Honyo Prototype, we combine advanced CNC technology with rigorous quality control to deliver precision-machined aluminum enclosures that meet the highest engineering standards.

From CAD to Part: The Process

Custom Aluminum Box Production Workflow: From CAD to Final Part

Our streamlined workflow for custom aluminum box manufacturing ensures precision, efficiency, and adherence to client specifications from initial concept through final delivery. This CNC machining process leverages advanced technology and engineering expertise, structured into three critical phases: AI-Powered Quoting, Comprehensive Design for Manufacturability (DFM) Review, and Precision Production.

The process initiates when a client submits a validated CAD model, typically in STEP or IGES format. Honyo Prototype’s proprietary AI quoting engine immediately analyzes the geometry, material requirements, and requested finish. This system cross-references real-time machine capacity, material costs, and labor rates to generate a highly accurate preliminary quote within hours, not days. The AI assessment provides initial feedback on basic manufacturability constraints, setting clear expectations before formal engineering engagement.

Following quote acceptance, the project enters the mandatory DFM review stage. Our senior manufacturing engineers conduct a rigorous, hands-on analysis of the CAD model, focusing specifically on CNC machining feasibility for aluminum enclosures. We scrutinize wall thickness uniformity, internal corner radii, feature accessibility for standard tooling, tolerance stack-ups, and optimal stock size selection. Critical considerations include minimizing setups to reduce cost and error potential, ensuring adequate clearance for milling cutters in internal cavities, and verifying that specified surface finishes are achievable with the chosen alloy. This phase often involves direct collaboration with the client to suggest subtle, non-functional design optimizations that significantly enhance manufacturability without compromising performance. Material selection is a key outcome, with 6061-T6 aluminum being the standard recommendation due to its optimal balance of machinability, strength, and corrosion resistance for enclosures.

Upon DFM sign-off, production commences on our state-of-the-art CNC machining centers. The workflow begins with meticulous material preparation, selecting the appropriate aluminum billet or plate based on the final box dimensions. Precision fixturing ensures absolute stability during machining. Milling operations proceed in carefully sequenced stages: roughing to remove bulk material, semi-finishing to achieve near-net shape, and final precision finishing passes to meet tight tolerances and surface quality requirements. Complex boxes often require multi-axis machining (3+2 or full 5-axis) to access intricate internal features and compound angles in a single setup, minimizing handling errors. All critical dimensions undergo in-process inspection using calibrated CMMs or optical comparators. The process concludes with deburring, optional secondary operations like anodizing or bead blasting per specification, and final dimensional and visual quality assurance before packaging and shipment.

Standard Aluminum Material Specifications for Enclosures

| Property | 6061-T6 Aluminum | Typical Application in Boxes |

| :——————— | :————— | :———————————– |

| Ultimate Tensile Strength | 310 MPa (45 ksi) | Structural integrity of walls/lids |

| Yield Strength | 276 MPa (40 ksi) | Resistance to deformation under load |

| Elongation at Break | 12% | Impact resistance |

| Hardness (Brinell) | 95 | Machinability and wear resistance |

| Surface Finish (As Machined) | 3.2 – 6.3 μm Ra | Base requirement for most enclosures |

| Anodizing Compatibility| Excellent | Standard corrosion/wear protection |

This integrated workflow, from AI-driven quoting through expert DFM to precision CNC execution, ensures Honyo Prototype delivers custom aluminum enclosures that meet exacting functional and quality standards while optimizing time-to-market and cost efficiency for our clients. Rigorous quality control is embedded at every transition point within the process.

Start Your Project

Start Your Custom Aluminum Box Project with Precision Engineering at Shenzhen Honyo Prototype

When it comes to producing high-performance custom aluminum boxes for enclosures, control units, or industrial housings, precision, material integrity, and rapid turnaround are non-negotiable. At Shenzhen Honyo Prototype, we specialize in CNC-machined aluminum solutions that combine tight tolerances, superior surface finishes, and design flexibility—delivering functional prototypes and low-to-mid volume production runs with consistency and speed.

Our CNC machining capabilities are optimized for aluminum alloys commonly used in demanding environments, including 6061, 7075, and 5052. Whether your project requires intricate internal geometries, custom mounting features, EMI shielding, or anodized finishes, our in-house team ensures every detail is executed to specification. We leverage advanced 3-, 4-, and 5-axis CNC centers, supported by experienced process engineers who validate toolpaths, minimize material waste, and maintain repeatability across batches.

Starting your project is simple. Share your design files—preferably in STEP, IGES, or SolidWorks format—and our engineering team will conduct a comprehensive Design for Manufacturability (DFM) review. This step ensures optimal machinability, identifies potential cost-saving opportunities, and confirms compliance with your mechanical, thermal, and environmental requirements. We support tight tolerances down to ±0.005 mm and offer secondary operations including tapping, countersinking, laser engraving, and custom anodizing (clear, black, or colored).

To give you full visibility upfront, we provide detailed quotes within 12 hours of receiving your request. Lead times typically range from 7 to 12 business days, depending on complexity and volume, with expedited options available for urgent needs.

Below are standard technical specifications for our CNC-machined aluminum boxes:

| Feature | Specification |

|————————–|————————————————|

| Material Options | Aluminum 6061-T6, 7075-T6, 5052, 2024 |

| Tolerance | ±0.005 mm (standard), tighter on request |

| Max Work Envelope | 1200 × 800 × 500 mm |

| Surface Finish | As-machined, bead-blasted, anodized (Type II/III) |

| Secondary Operations | Tapping, threading, engraving, polishing, coating |

| File Formats Accepted | STEP, IGES, X_T, SolidWorks, PDF (for 2D) |

| Lead Time | 7–12 days (standard), expedited options available |

| MOQ | 1 piece (prototype) to 500+ units (production) |

We understand that every custom aluminum box serves a unique functional purpose—whether it’s protecting sensitive electronics, integrating into a larger assembly, or meeting strict industry certifications. That’s why we prioritize collaboration from the very first inquiry.

Ready to move forward? Contact Susan Leo, Customer Project Manager at Shenzhen Honyo Prototype, to initiate your project with confidence. Email her directly at info@hy-proto.com with your design files and requirements. Our team will respond promptly with a detailed quote, DFM feedback, and next steps tailored to your timeline and performance needs.

Partner with a manufacturer that combines technical expertise, agile production, and responsive support—because your prototype deserves nothing less than precision in every dimension.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.