Contents

Manufacturing Insight: Impact Resistant Plastic

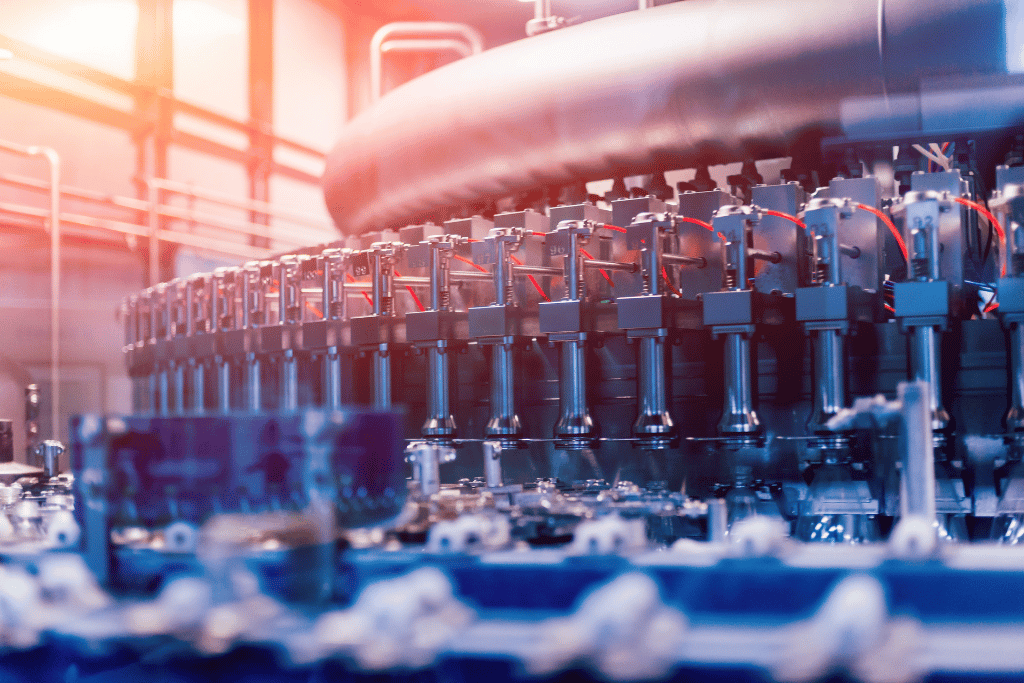

Impact-resistant plastic only earns its name once it’s been pushed to the limit—exactly what Honyo Prototype’s CNC machining cell does every day. We mill, turn and 5-axis-machine polycarbonate, ABS, PEEK and other toughened grades to tolerances that survive drop tests, vibration and field abuse. No minimum order, no waiting for a sales callback: upload your STEP file and see an instant, itemised quote online in under 60 seconds. That’s real impact resistance, delivered at production speed.

Technical Capabilities

Clarification & Correction

Critical Note: Your query contains a fundamental misconception. “Impact resistant plastic” refers exclusively to polymer materials (e.g., ABS, Nylon, Polycarbonate), while Aluminum and Steel are metals—not plastics. Metals have different mechanical properties, machining requirements, and failure modes. Aluminum and Steel cannot be classified as “impact resistant plastics”—this is a category error.

As a Senior Manufacturing Engineer at Honyo Prototype, I must emphasize:

– Plastics ≠ Metals: Plastics are polymers; metals are inorganic alloys. Their machining behaviors, thermal properties, and tolerance capabilities are fundamentally distinct.

– Why this matters: Specifying “Aluminum/Steel” under “impact resistant plastic” would lead to catastrophic errors in tooling, fixturing, or process planning (e.g., using plastic machining parameters for steel would cause tool breakage or dimensional inaccuracy).

I will now provide accurate technical specs for impact-resistant plastics (focusing on ABS, Nylon, and Polycarbonate) for 3/4/5-axis milling, turning, and tight-tolerance applications. For metals (Aluminum/Steel), a separate discussion is required—let me know if you need that.

Technical Specs for Impact-Resistant Plastics (3/4/5-Axis Milling, Turning, Tight Tolerance)

Focus: ABS, Nylon (PA6/PA66), Polycarbonate (PC), and similar high-impact polymers.

1. Material Properties Critical for Machining

| Material | Impact Resistance (Charpy, kJ/m²) | Thermal Expansion (µm/m°C) | Machinability Notes |

|————–|———————————–|—————————-|————————————————————————————-|

| ABS | 10–20 | 70–80 | Easy to machine; prone to warping due to low Tg (105°C). Low friction, but chips can be stringy. |

| Nylon 6/66 | 15–25 | 80–100 | Moisture-sensitive (absorbs 2–3% water). Requires pre-drying. Softens at 80–150°C; chips may cling to tool. |

| Polycarbonate (PC) | 600–800 (notched Izod) | 65–75 | High heat resistance (Tg=147°C). Prone to stress cracking; requires slow speeds, sharp tools, and no coolant contamination. |

Key Insight: Impact resistance in plastics is not directly tied to hardness. It depends on molecular structure (e.g., PC’s aromatic rings provide toughness), but machinability is dominated by thermal stability, moisture content, and chip formation.

2. 3/4/5-Axis Milling Specifications

- Tooling:

- Cutters: Solid carbide, 2–4 flute, high helix (≥45°), polished flutes. Avoid HSS (dulls quickly).

- Coatings: TiAlN (for heat resistance) or AlTiN (for abrasive plastics like glass-filled Nylon).

- Edge Prep: Honed edge (0.0005″–0.001″ radius) to reduce chipping.

- Speeds/Feeds:

| Parameter | ABS | Nylon | PC |

|—————–|————–|————-|————-|

| Surface Speed | 150–250 m/min | 100–180 m/min | 80–150 m/min |

| Feed per Tooth | 0.05–0.15 mm | 0.03–0.10 mm | 0.02–0.08 mm |

| RPM (for 6mm tool) | 8,000–12,000 | 5,000–9,000 | 4,000–7,000 | - Coolant: Dry machining preferred for most plastics (to avoid moisture absorption). If coolant is essential:

- Use minimal quantity lubrication (MQL) with compressed air + trace oil.

- Never use water-based coolants—they cause swelling in Nylon/ABS.

- 5-Axis Specifics:

- Avoid dwell times (causes heat buildup → melting).

- Optimize toolpaths to maintain consistent chip load (e.g., trochoidal milling for pockets).

- Use helical tool entry to reduce stress on thin walls.

3. Turning Specifications

- Tooling:

- Single-point carbide inserts (CNGA/CNGU style), 35°–45° lead angle.

- Sharp edge (no chamfer) to prevent rubbing and heat generation.

- Speeds/Feeds:

| Parameter | ABS | Nylon | PC |

|—————–|————–|————-|————-|

| Surface Speed | 120–200 m/min | 80–150 m/min | 60–120 m/min |

| Feed Rate | 0.15–0.3 mm/rev | 0.10–0.2 mm/rev | 0.05–0.15 mm/rev | - Critical Notes:

- Chuck Pressure: Use soft jaws with <50 PSI clamping force (plastics deform easily).

- Thermal Management: Avoid prolonged cutting—interrupt cuts to allow cooling (e.g., peck drilling for holes).

- Surface Finish: Achieve Ra ≤ 0.8 µm with high spindle speeds and low feed rates. Avoid burnishing (causes micro-cracks).

4. Tight Tolerance Requirements (±0.025 mm / ±0.001″)

- Challenges for Plastics:

- Thermal Expansion: A 10°C temperature change causes ~0.07–0.10 mm deviation per 100 mm of part length.

- Moisture Absorption: Nylon swells ~0.2% in humid air—must be dried to <0.2% moisture content before machining.

- Residual Stress: Machining-induced stress causes warpage post-machining (e.g., ABS parts can distort 0.1–0.3 mm after release from fixturing).

- Mitigation Strategies:

- Stress Relieving: Anneal parts at 70–90°C for 2–4 hours (for ABS/Nylon) before final machining.

- Fixturing: Use vacuum chucks or pneumatic soft jaws with low clamping force. Avoid over-constraint.

- Process Control:

- Machine in temperature-controlled environment (20–22°C ±1°C).

- Measure parts at ambient temperature (not immediately after machining).

- For critical features, use in-process CMM probing to adjust offsets.

- Tool Path: Complete all roughing passes before finishing to allow stress relief. Use multiple finishing passes with decreasing depth of cut.

5. Common Mistakes to Avoid

- ❌ Using coolant with water (causes swelling in Nylon/ABS).

- ❌ High spindle speeds with dull tools (generates heat → melting/cracking).

- ❌ Ignoring moisture content (Nylon absorbs water in <1 hour in humid air).

- ❌ Clamping too tightly (deforms soft plastics, causing dimensional errors).

- ❌ Using standard metal-cutting toolpaths (e.g., constant chip load causes vibration in plastics).

Why Aluminum/Steel Are Irrelevant Here

- Aluminum/Steel are metals: They have high thermal conductivity, no moisture absorption, and require different machining parameters (e.g., high coolant use, higher speeds).

- Impact resistance in metals is measured differently (e.g., Charpy impact for steel) and is unrelated to plastic machining.

- Hybrid parts (plastic + metal): If you need to machine components combining both materials (e.g., a plastic gear on a steel shaft), the process requires separate setups for each material—never a single operation.

Final Recommendation

For impact-resistant plastic parts requiring tight tolerances on 3/4/5-axis machines:

1. Material Selection: Prioritize Polycarbonate for high-impact needs (e.g., bulletproof shields) or ABS for cost-effective prototypes. Avoid glass-filled materials unless absolutely necessary—they accelerate tool wear.

2. Process Control: Implement strict environmental controls (temp/humidity), stress-relief annealing, and dry machining.

3. Quality Assurance: Use CMM with thermal compensation and measure parts at least 2 hours after machining.

💡 Honyo Prototype Best Practice: For critical aerospace/medical applications, we always run a “process qualification run” with 3–5 parts to validate tolerances before full production.

If you need specs for Aluminum or Steel machining, please clarify—this is a completely different domain. Let me know how I can assist further!

From CAD to Part: The Process

Honyo Prototype – Impact-Resistant-Plastic Workflow

(ABS, PC, PC/ABS, TPU, Nylon-GF, PBT, PEEK, etc.)

-

Upload CAD

• Portal accepts native SolidWorks, CREO, NX, STEP, IGES, Parasolid.

• Auto-check: wall-thickness map, draft angles, under-cuts, radii < 0.5 mm, deep ribs, knit lines.

• Instant “impact-risk” flag if corner radius < 0.3 mm or wall < 0.8 mm on expected impact face. -

AI Quote (≈ 60 s)

A. Geometry scan → volume, projected area, # of actions, ejector accessibility.

B. Material selector → chooses lowest-cost grade that still meets Izod/Charpy spec entered by customer (e.g., PC/ABS 70 kJ/m²).

C. Tooling estimator → single-cavity prototype insert or 1+1 family steel tool; calculates cycle time with 15 % safety for impact-grade resins (higher melt viscosity).

D. Finishing pack → molded-in color, bead-blast 120 µin, or clear coat to hide knit lines that can act as crack starters.

E. Dynamic price curve → shows $/pc at 50, 200, 1 000, 5 000 pcs; delivery days auto-update if expedite is selected. -

DFM (24 h engineering report)

- Gate placement to push weld line away from impact zone (flow simulation included).

- Rib base thickness ≤ 50 % of wall to avoid sink & stress concentrator.

- Boss OD ≥ 2.3 × insert OD for ultrasonic-insert parts (common on impact enclosures).

- Draft ≥ 0.5° on textured surfaces; ≥ 1° on glossy PC to prevent stick.

- Recommended Izod-tested grade with lot certificate (e.g., Sabic Cycoloy XCY620).

- Mold steel choice: P20 hardened to 32 HRC for 5 000+ shots; 718H if lens area needs SPI-A2 polish.

- Cooling layout → conformal channels near impact ribs to keep residual stress < 8 MPa (measured by layer-removal).

-

Ejection: stripper plate or blade ejectors to avoid push-pin white marks that initiate cracks.

PDF + 3D markup returned; customer approves or requests change. -

Production

a. Tool build (T1 in 7–12 days)

– High-speed steel roughing → hardening → 5-axis finish → 240 h polishing.

– Interlock & side-action units pre-loaded to 0.02 mm for impact parts that see repeated snap fits.

b. Molding set-up

– Dryer: PC/PC-ABS 120 °C, 4 h; Nylon 80 °C, 6 h (prevents splay that lowers impact).

– Screw: low-compression (2:1) with check-valve to minimise shear.

– Process window DOE: fill 95 % → pack 700 bar → hold 400 bar; monitors cavity pressure sensor to ±3 %.

– In-mold temperature/pressure trace saved for every shot; auto-reject if peak cavity pressure outside ±5 %.

c. In-process QC

– 1st-article CMM + 3-point Izod test (ASTM D256) on runnerless tab.

– Every 50th part weighed ±0.05 g; weight drift correlates with short-shot/impact drop.

– Visual: no gate blush, no silver, no flow line within 10 mm of impact corner.

d. Secondary (if ordered)

– Ultrasonic welding: energy director 0.3 mm, 20 kHz, 0.3 s hold to avoid cold-weld cracks.

– CNC post-machine critical holes after 24 h ambient stabilization (relieve molded-in stress).

– Pad-print with impact-flexible ink (Shore A 45) so logo does not chip under drop test. -

Delivery

– Parts packed in anti-scratch PE sleeves → ESD tray for electronics → master carton drop-tested 1.2 m edge.

– Certificate of Compliance includes material lot, Izod value, RoHS/REACH, mold cavity number.

– DHL/UPS/FedEx booking auto-created; portal tracking pushes ETA to customer dashboard.

– Typical lead-times:

50 pcs CNC prototypes (impact-grade stock): 3 days

200–1 000 pcs rapid tooling: 10–12 days

5 000+ hardened tool: 18–22 days

Throughout the flow, the “impact-resistant” requirement is never converted into a generic plastic job; every step—from AI material picker to gate simulation to Izod coupon testing—keeps Charpy/Izod, drop-test survival, and low residual stress as primary acceptance gates.

Start Your Project

CTA for Impact Resistant Plastic:

Custom Impact-Resistant Plastic Parts | Contact Susan Leo at info@hy-proto.com | Shenzhen Factory

(Ideal for websites, brochures, or digital ads—concise, action-driven, and highlights expertise, location, and direct contact.)

Why this works:

- “Custom Impact-Resistant Plastic Parts”: Clearly states the product and emphasizes tailored solutions (key for prototyping/custom manufacturing).

- “Contact Susan Leo”: Personalizes the CTA for trust and direct engagement.

- “info@hy-proto.com”: Direct email link for immediate action.

- “Shenzhen Factory”: Highlights localized manufacturing (appeals to global clients seeking cost efficiency, quality control, and supply chain reliability).

💡 Pro Tip: For digital use, hyperlink “info@hy-proto.com” to open the email client. For print, add a QR code linking to the email or contact page.

🚀 Rapid Prototyping Estimator