Contents

Manufacturing Insight: Is Cnc Machining A Good Career

Manufacturing Insight: CNC Machining as a Strategic Asset for Modern Production

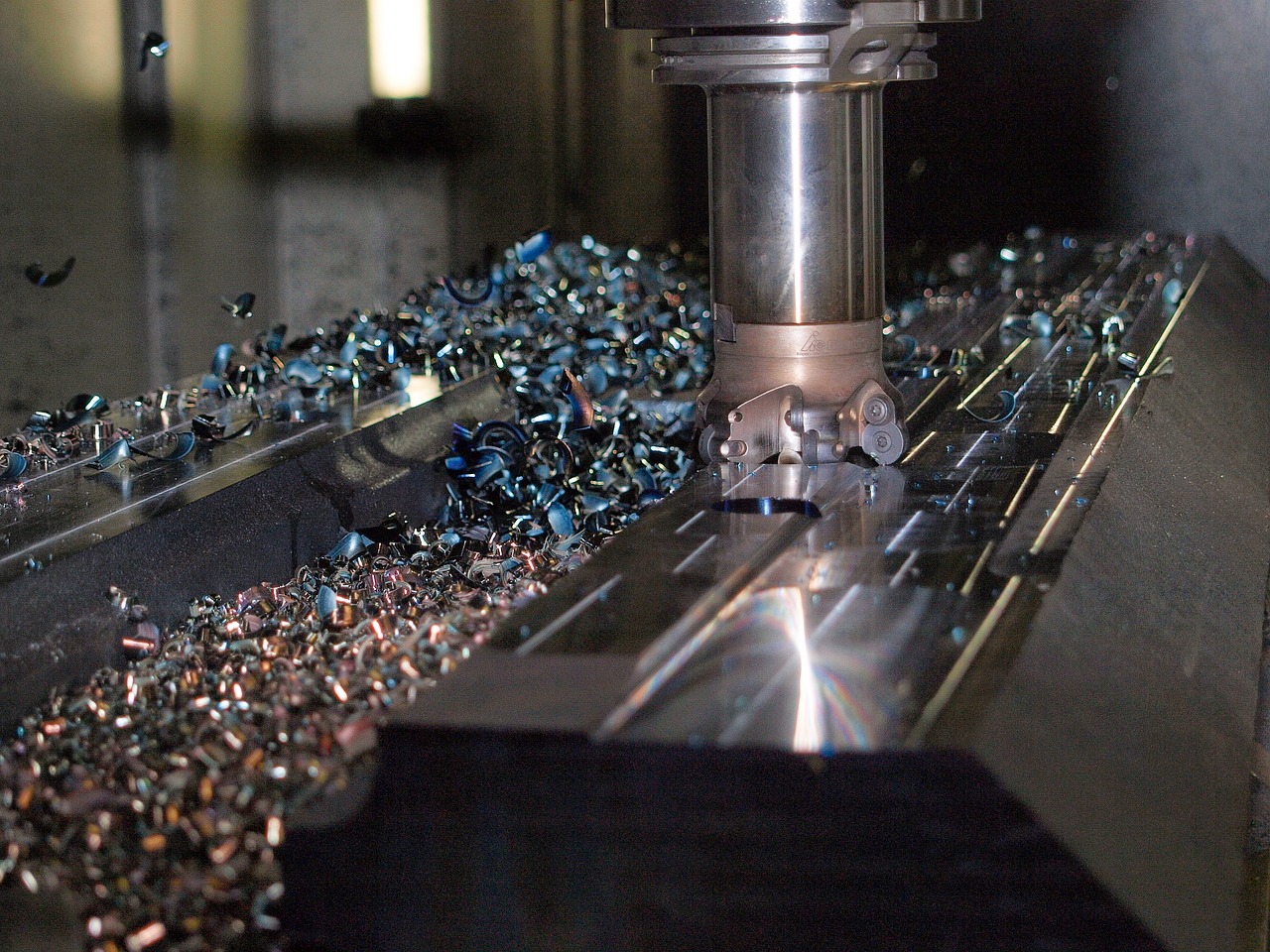

CNC machining remains a cornerstone technology in precision manufacturing, delivering exceptional repeatability, material versatility, and geometric complexity unattainable through manual methods. For businesses requiring high-integrity components across aerospace, medical, automotive, and consumer electronics sectors, CNC capabilities are not merely advantageous—they are fundamental to competitive product development and production. Shenzhen Honyo Prototype leverages this critical technology as the backbone of our rapid prototyping and low-volume production services, enabling clients to transform digital designs into functional, production-ready parts with speed and accuracy. The enduring relevance of CNC stems from its adaptability; continuous advancements in multi-axis control, high-speed machining, and integrated metrology ensure it meets evolving industry demands for tighter tolerances and complex geometries.

At Honyo, our investment in state-of-the-art CNC infrastructure directly translates to client value. We operate a diversified fleet of machines optimized for diverse project requirements, balancing throughput, precision, and material compatibility. Our capabilities encompass milling, turning, and multi-tasking operations, supporting a broad spectrum of engineering alloys, plastics, and composites. Key technical specifications of our core equipment platform include:

| Machine Type | Maximum Work Envelope (mm) | Typical Tolerance (mm) | Spindle Speed (RPM) | Lead Time (Prototype) |

| :—————– | :————————: | :——————–: | :—————–: | :——————-: |

| 3-Axis Vertical Mill | 1000 x 600 x 500 | ±0.01 | 24,000 | 3-5 Working Days |

| 5-Axis Mill-Turn | Ø300 x 400 | ±0.005 | 12,000 | 5-7 Working Days |

| High-Speed Mill | 800 x 500 x 400 | ±0.008 | 42,000 | 2-4 Working Days |

This technical foundation is augmented by rigorous process control. Every CNC operation at Honyo adheres to documented work instructions, utilizes calibrated tooling and fixtures, and undergoes in-process inspection using CMMs and optical comparators. Our engineers employ advanced CAM strategies to optimize toolpaths, minimize cycle times, and ensure surface finishes meet stringent application requirements—often achieving Ra values below 0.8 µm without secondary operations. Material utilization is maximized through nesting software and strategic fixturing, reducing waste and cost for clients.

The sustained demand for skilled CNC programming, operation, and process engineering underscores the technology’s strategic importance within the manufacturing ecosystem. Honyo actively contributes to workforce development through structured apprenticeships and continuous upskilling, recognizing that human expertise remains irreplaceable in optimizing machine performance and solving complex production challenges. For manufacturers, partnering with a provider possessing deep CNC proficiency like Honyo Prototype mitigates prototyping risk, accelerates time-to-market, and provides a scalable pathway from validation to pilot production. In an environment where component precision directly impacts product performance and regulatory compliance, robust CNC machining capability is not just a viable career path for technicians—it is an indispensable strategic asset for any forward-looking engineering enterprise. Honyo stands ready to deploy this asset in service of our clients’ most demanding projects.

Technical Capabilities

Technical Capabilities in CNC Machining: A Foundation for Career Growth

CNC machining remains a cornerstone of modern manufacturing, offering precision, repeatability, and scalability across industries such as aerospace, medical devices, automotive, and consumer electronics. At Shenzhen Honyo Prototype, our advanced CNC machining capabilities empower engineers and product developers to transform concepts into high-performance prototypes and low-to-mid volume production parts. For professionals considering a career in this field, understanding the technical depth and precision required in CNC operations is critical to long-term success and advancement.

Our core competencies include 3-axis, 4-axis, and 5-axis milling, as well as CNC turning for complex rotational geometries. Each platform offers distinct advantages, enabling us to accommodate a broad range of part complexities and production requirements. 3-axis milling provides high-speed, cost-effective solutions for prismatic parts with straightforward geometries. 4-axis machining introduces rotational capability around the X-axis, allowing for indexing operations and increased feature accessibility. 5-axis CNC milling, the most advanced offering, enables simultaneous movement across five axes, delivering exceptional accuracy for complex freeform surfaces—common in aerospace impellers, medical implants, and ergonomic tooling.

Complementing our milling capabilities, our CNC turning centers support the production of cylindrical and symmetrical components with tight geometric control. Multi-axis turning centers with live tooling allow for complete part fabrication in a single setup, reducing cycle times and enhancing dimensional consistency.

A defining hallmark of our service is the ability to maintain tight tolerances across diverse materials. Typical tolerances range from ±0.005 mm to ±0.05 mm, depending on geometry, size, and material. Critical features such as hole alignment, flatness, and thread accuracy are consistently held within customer specifications using calibrated tooling, in-process probing, and post-process inspection with coordinate measuring machines (CMMs).

The table below outlines our standard tolerance capabilities and compatible materials:

| Process | Typical Tolerance | Maximum Part Size (mm) | Common Materials |

|——————–|——————-|————————|——————|

| 3-Axis Milling | ±0.01 mm | 600 x 400 x 300 | Aluminum 6061, 7075, Stainless Steel 303, 316, Brass C360, POM, PC, ABS |

| 4-Axis Milling | ±0.01 mm | 500 x 400 x 250 | Aluminum 6061, 7075, Titanium Grade 5, PEEK, Delrin |

| 5-Axis Milling | ±0.005 mm | 400 x 400 x 200 | Inconel 718, Titanium, Magnesium, Carbon Fiber Reinforced Polymers |

| CNC Turning | ±0.01 mm | Ø300 x 500 | Stainless Steel 303/316, Aluminum 6061, Brass, Titanium, PEEK |

Mastery of these technical parameters not only defines a high-quality machining service but also underscores the value of skilled operators and programmers in the industry. A career in CNC machining demands continuous learning in G-code programming, toolpath optimization, workholding design, and metrology. As automation and Industry 4.0 integration grow, professionals with hands-on experience in multi-axis systems and tight-tolerance production are increasingly in demand.

At Honyo Prototype, we invest in both technology and talent, ensuring that our team remains at the forefront of precision manufacturing. For individuals seeking a technically rigorous and future-proof career, CNC machining offers a compelling path with measurable impact and global relevance.

From CAD to Part: The Process

From CAD to Part: The CNC Machining Workflow at Honyo Prototype

At Shenzhen Honyo Prototype, transforming a digital CAD model into a high-precision physical component follows a rigorously defined workflow, integrating automation with critical human expertise. This process underpins the viability and technical depth of a CNC machining career, demanding continuous skill application beyond simple operation. The journey begins with the AI-Powered Quoting System. Upon receiving a customer’s 3D CAD file (typically STEP or IGES format), our proprietary AI engine rapidly analyzes geometry, material requirements, and initial tolerances. It cross-references this data against extensive databases covering material costs, machine hourly rates, tooling availability, and historical process times to generate a preliminary quote within minutes. Crucially, this AI output is not final; experienced manufacturing engineers must validate the AI’s assumptions, particularly regarding complex features, non-standard materials, or exceptionally tight tolerances that may require specialized processes. This stage highlights the first essential career skill: interpreting AI output and applying practical manufacturing knowledge to ensure quote accuracy and feasibility.

The validated project then enters Design for Manufacturability (DFM) Review, a collaborative phase where engineering and production teams scrutinize the design. This is where deep CNC process knowledge becomes indispensable. Engineers assess feature geometry for machinability, identify potential tool access issues, evaluate the necessity of tight tolerances versus cost, and suggest modifications to reduce setup changes or material waste. Effective DFM requires understanding cutter dynamics, workholding limitations, and secondary operation requirements. A typical DFM checklist includes:

| DFM Check Item | Severity | Common Resolution |

| :———————- | :——- | :———————————— |

| Internal Corner Radius | Critical | Recommend larger radius or T-bone slot |

| Thin Walls / Fins | High | Suggest thickness increase or ribbing |

| Deep Cavities | Moderate | Propose step-drilling or EDM solution |

| Non-Standard Tolerances | High | Clarify necessity or adjust GD&T |

Following DFM approval and any necessary design iterations, the project moves to Production Execution. CNC programmers generate optimized toolpaths using CAM software, selecting appropriate cutters, feeds, speeds, and strategies (e.g., high-speed machining, trochoidal milling). Setup technicians meticulously prepare the machine: securing the workpiece in custom or standard fixtures, loading tooling into the magazine, and establishing precise work offsets. During machining, operators monitor the process, performing critical in-process inspections using calibrated tools like micrometers and height gauges. Complex parts often require multiple setups on 3-axis, 4-axis, or 5-axis machines. Final inspection against the original CAD model using Coordinate Measuring Machines (CMMs) or optical comparators ensures compliance with specifications. Typical precision capabilities include:

| Feature Type | Standard Tolerance | Tight Tolerance Capability |

| :—————– | :—————– | :————————- |

| Linear Dimensions | ±0.05 mm | ±0.005 mm |

| Hole Diameter | ±0.03 mm | ±0.01 mm (reamed) |

| Flatness | 0.05 mm | 0.005 mm |

| Positional Accuracy| ±0.05 mm | ±0.01 mm |

This integrated workflow – from AI-assisted quoting through expert DFM to precision production – demonstrates why CNC machining offers a robust career path. It demands constant problem-solving, technical adaptation, and responsibility for quality and efficiency, ensuring human expertise remains irreplaceable even as automation advances. Success hinges on mastering both the software and the physical realities of metal removal.

Start Your Project

Is CNC Machining a Good Career? Start Your Journey with Honyo Prototype

CNC machining remains a cornerstone of modern manufacturing, combining precision engineering with advanced technology to produce high-quality components across aerospace, automotive, medical, and consumer electronics industries. For professionals seeking a stable and technically rewarding career, CNC machining offers long-term growth, competitive wages, and the opportunity to work on cutting-edge projects. At Shenzhen Honyo Prototype, we don’t just provide machining services—we support the next generation of manufacturing talent by delivering real-world project experience and industry-grade capabilities.

If you’re evaluating CNC machining as a career path, hands-on experience is essential. Understanding G-code, mastering CAD/CAM software, and learning how to operate milling and turning centers are foundational skills that open doors to advanced roles in automation, quality control, and production management. At Honyo Prototype, we use state-of-the-art 3-, 4-, and 5-axis CNC machines, allowing engineers and technicians to work with tight tolerances, complex geometries, and a wide range of materials—from aluminum and stainless steel to titanium and engineering plastics.

Our facility in Shenzhen is equipped to handle low-volume prototypes and high-mix production runs, making it an ideal environment for those looking to learn and grow in precision manufacturing. Whether you’re a student, recent graduate, or professional transitioning into manufacturing, exposure to real production workflows, quality assurance protocols, and rapid prototyping methodologies can significantly accelerate your career development.

We invite individuals and organizations interested in CNC machining—whether for career exploration, project collaboration, or production support—to connect with our team. At Honyo Prototype, we specialize in fast turnaround, high-accuracy machining with full traceability and inspection reporting. Our engineering team works closely with clients to optimize designs for manufacturability, reduce lead times, and ensure compliance with industry standards.

To learn more about how we can support your CNC machining goals—whether you’re starting a project, exploring career opportunities, or seeking technical guidance—contact Susan Leo, our Project Coordinator. She will assist you in initiating your project, providing quotes, and connecting you with our engineering resources.

Contact Information

Susan Leo

Project Coordinator, Shenzhen Honyo Prototype

Email: info@hy-proto.com

Below are key specifications of our CNC machining capabilities to help you evaluate feasibility and alignment with your project requirements.

| Specification | Detail |

|—————————|—————————————–|

| Machine Types | 3-axis, 4-axis, 5-axis CNC milling, CNC turning |

| Maximum Work Envelope | 1000 mm × 600 mm × 500 mm (XYZ) |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Materials Available | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass, PEEK, ABS, Polycarbonate |

| Lead Times | As fast as 3–5 business days |

| Surface Finishes | As-machined, Anodizing (Type II), Bead blasting, Powder coating, Passivation |

| Quality Standards | ISO 9001:2015 compliant, Full inspection reports (CMM available) |

Start your CNC machining project today—and take a decisive step toward a future in advanced manufacturing.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.