Contents

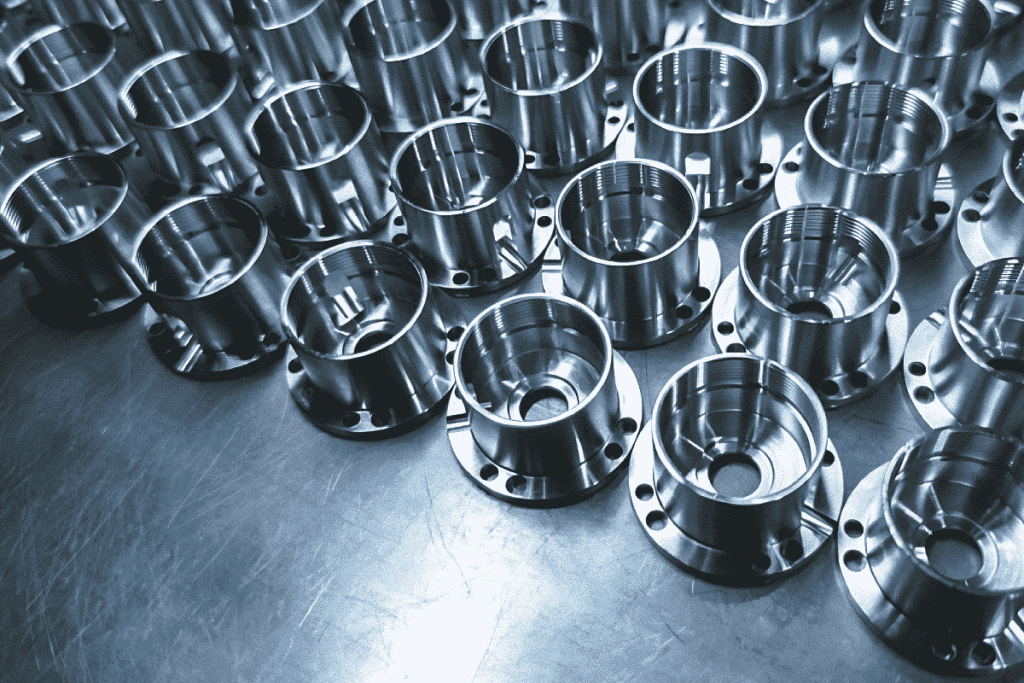

Manufacturing Insight: Stainless Steel Pieces

Manufacturing Insight: Stainless Steel CNC Machining Capabilities

Stainless steel remains a cornerstone material in precision engineering due to its exceptional corrosion resistance, mechanical strength, and versatility across aerospace, medical, and industrial applications. At Shenzhen Honyo Prototype, we specialize in transforming complex stainless steel designs into high-integrity components through advanced CNC machining. Our expertise addresses the inherent challenges of machining these alloys—including work hardening, thermal conductivity limitations, and tool wear—while maintaining tight tolerances and surface finishes essential for mission-critical parts.

Stainless steel’s high ductility and tendency to generate heat during cutting demand meticulous process control. We leverage high-rigidity CNC centers with specialized toolpath strategies to minimize chatter and thermal distortion. Our engineers optimize spindle speeds, feed rates, and coolant delivery to counteract work hardening, particularly in austenitic grades like 304 and 316. For martensitic or precipitation-hardening alloys such as 17-4PH, we implement secondary heat treatment protocols to ensure dimensional stability post-machining. Rigorous in-process inspections using coordinate measuring machines (CMMs) guarantee compliance with ISO 2768-mK or customer-specific geometric tolerancing standards.

Honyo’s capabilities extend from rapid prototyping to low-volume production, supported by a material library spanning common and exotic stainless grades. Below is a reference table outlining key alloys we routinely machine and their critical machining considerations:

| Stainless Steel Grade | Key Properties | Machinability Notes | Common Applications |

|———————–|————————————|——————————————————|———————————–|

| 303 | Free-machining sulfur additive | Highest machinability; prone to sulfur-related corrosion | Shafts, fasteners, valves |

| 304/L | General-purpose austenitic | Moderate work hardening; requires sharp tools | Food processing, chemical tanks |

| 316/L | Molybdenum-enhanced corrosion res | Higher work hardening than 304; aggressive cooling | Marine, pharmaceutical equipment |

| 17-4PH | Precipitation-hardening martensitic | Machines in annealed state; final heat treat post-CNC | Aerospace actuators, molds |

Our workshop utilizes carbide tooling with PVD coatings (e.g., TiAlN) to extend tool life and maintain edge integrity when cutting abrasive alloys. We strictly control chip evacuation to prevent re-cutting, which can compromise surface integrity. For critical medical or hydraulic components, we achieve Ra 0.4 µm surface finishes through multi-stage finishing passes and vibration-dampened tooling setups. Material certifications (e.g., Mill Test Reports) and full traceability are standard for all production batches, ensuring compliance with ASME, ASTM, or customer-specific material specifications.

Honyo Prototype’s integrated approach—combining material science expertise, adaptive machining strategies, and stringent quality validation—delivers stainless steel components that meet the most demanding performance requirements. By partnering with us, clients gain access to a streamlined process that reduces lead times without sacrificing the precision essential for high-reliability applications. We transform material challenges into engineering advantages, ensuring your stainless steel prototypes and production parts perform flawlessly in real-world conditions.

Technical Capabilities

Technical Capabilities: CNC Machining of Stainless Steel Components

Shenzhen Honyo Prototype delivers precision CNC machining services for stainless steel components, supporting industries that demand high strength, corrosion resistance, and dimensional accuracy. Our facility is equipped with advanced 3-axis, 4-axis, and 5-axis milling centers, as well as multi-axis CNC turning machines, enabling us to produce complex geometries with tight tolerances and superior surface finishes. We specialize in prototyping and low-to-mid volume production runs, ensuring flexibility and rapid turnaround without compromising on quality.

Our 3-axis milling systems are ideal for prismatic parts with straightforward geometries, offering high-speed material removal and excellent repeatability. For more complex features such as undercuts, compound angles, or sculpted surfaces, our 4-axis and 5-axis CNC mills provide enhanced tool accessibility, reducing the need for multiple setups and improving overall accuracy. Simultaneous 5-axis machining allows for intricate contours and organic shapes commonly found in aerospace, medical, and automation components.

In addition to milling, our CNC turning capabilities support the production of cylindrical and symmetrical stainless steel parts. Equipped with live tooling, our turning centers can perform milling, drilling, and tapping operations in a single setup, minimizing handling and ensuring concentricity. This integrated approach is particularly beneficial for shafts, fittings, and valve components.

We maintain strict process controls to achieve tight tolerances across all machining operations. Standard tolerances are held to ±0.05 mm, with critical dimensions achievable down to ±0.005 mm when required. Surface finishes range from 3.2 µm to 0.8 µm Ra, depending on part geometry and customer specifications. All components undergo in-process and final inspection using calibrated CMMs, optical comparators, and surface roughness testers to ensure compliance with engineering requirements.

The following table outlines our standard material offerings and achievable tolerances for stainless steel machining:

| Material Grade | Common Applications | Standard Tolerance (mm) | Tight Tolerance (mm) | Max Part Size (mm) | Surface Finish (Ra, µm) |

|———————-|—————————–|————————–|————————|——————–|————————–|

| 303 Stainless Steel | Fasteners, shafts, gears | ±0.05 | ±0.01 | 500 x 400 x 300 | 0.8 – 3.2 |

| 304 / 304L | Enclosures, food equipment | ±0.05 | ±0.005 | 600 x 500 x 400 | 1.6 – 3.2 |

| 316 / 316L | Marine, medical, chemical | ±0.05 | ±0.005 | 600 x 500 x 400 | 0.8 – 2.5 |

| 17-4 PH | Aerospace, high-strength | ±0.05 | ±0.01 | 400 x 300 x 250 | 0.8 – 1.6 |

| 440C | Bearings, cutting tools | ±0.05 | ±0.01 | 300 x 250 x 200 | 0.4 – 1.6 |

All stainless steel parts are machined using optimized toolpaths, coolant-through tooling, and rigid fixturing to minimize deflection and thermal variation. Material certifications and full inspection reports are available upon request. At Shenzhen Honyo Prototype, we combine advanced CNC technology with rigorous quality assurance to deliver stainless steel components that meet the highest standards of performance and reliability.

From CAD to Part: The Process

Stainless Steel CNC Machining Workflow: From CAD to Precision Part

At Shenzhen Honyo Prototype, our stainless steel CNC machining process integrates advanced digital tools with precision manufacturing to deliver high-integrity components. This workflow ensures efficiency, quality, and adherence to stringent technical requirements from initial inquiry to final shipment. The process begins with an AI-Powered Quotation System, where uploaded CAD files undergo automated analysis. Our proprietary AI engine evaluates geometry complexity, material utilization, and machine time against real-time shop floor data. For stainless steel (primarily 304/L and 316/L), the system factors in grade-specific challenges like work hardening tendencies, thermal conductivity, and required toolpath strategies. This generates an accurate, data-driven quote within 2 hours, including lead time estimates and preliminary cost breakdowns—eliminating manual interpretation delays.

Following client approval, the project enters Design for Manufacturability (DFM) Review, a critical phase for stainless steel components. Our engineering team conducts a rigorous analysis focused on material-specific optimizations. We verify wall thickness stability to prevent chatter during milling, assess internal corner radii to minimize tool deflection, and validate tolerances against stainless steel’s machining characteristics. Key considerations include optimizing coolant flow for heat dissipation (critical to avoid galling), recommending appropriate tool coatings (e.g., TiAlN for 316 stainless), and suggesting feature modifications to enhance chip evacuation. Clients receive a collaborative DFM report with actionable recommendations, ensuring the design aligns with CNC capabilities while maintaining structural integrity and corrosion resistance.

Production Execution commences only after DFM sign-off. Raw 304/316 stainless steel stock undergoes rigorous material certification verification. Machining occurs on Haas and DMG MORI 5-axis centers with high-pressure coolant systems, configured for optimal spindle speeds and feed rates to manage stainless steel’s low thermal conductivity. In-process inspections using Renishaw probes verify critical dimensions after roughing and semi-finishing stages. Final parts undergo precision CMM validation against GD&T callouts, followed by mandatory post-processing: vibratory deburring, passivation (per ASTM A967), and optional electropolishing for medical/aerospace applications. Every component ships with full traceability documentation, including material certs, CMM reports, and process validation records.

Critical Stainless Steel Machining Specifications

| Parameter | Standard Specification | Precision Capability | Notes |

|——————–|—————————–|—————————-|—————————————-|

| Material Grades | 304/L, 316/L, 17-4PH | Custom grades on request | Material certs provided with shipment |

| Tolerance (Linear) | ±0.05 mm | ±0.0125 mm | Achieved via thermal compensation |

| Surface Finish | 3.2 μm Ra | 0.8 μm Ra | Electropolishing achieves 0.2 μm Ra |

| Max Part Size | 1000 x 600 x 500 mm | Custom fixtures available | 5-axis capability reduces setups |

This integrated workflow—AI quoting, stainless-optimized DFM, and controlled production—ensures Honyo Prototype delivers dimensionally accurate, corrosion-resistant stainless steel components with repeatable quality. Our closed-loop process minimizes rework risks while meeting aerospace, medical, and industrial sector demands for certified precision. All stages are governed by ISO 9001:2015 protocols, with real-time production data accessible to clients via our secure portal.

Start Your Project

Start Your Stainless Steel CNC Machining Project with Confidence

When precision, durability, and corrosion resistance are non-negotiable, stainless steel remains the material of choice across aerospace, medical, automotive, and industrial applications. At Shenzhen Honyo Prototype, we specialize in high-accuracy CNC machining of stainless steel components, transforming your design concepts into fully functional, production-ready parts. Whether you’re developing a prototype or scaling into low-volume production, our advanced manufacturing capabilities ensure consistency, tight tolerances, and superior surface finishes.

Our CNC machining services support a wide range of stainless steel grades, including 303, 304, 316, 17-4 PH, and 440C, each selected for specific mechanical and environmental performance. With state-of-the-art 3-axis and 4-axis CNC centers, automated tooling systems, and rigorous in-process inspection protocols, we deliver parts that meet exacting engineering specifications. Our facility is ISO 9001-certified, and every component undergoes dimensional verification using coordinate measuring machines (CMM) and surface roughness testers to ensure compliance with your technical requirements.

We understand that every project begins with a vision. That’s why our engineering team collaborates closely with clients during the design-for-manufacturability (DFM) phase, providing actionable feedback to optimize part geometry, reduce lead times, and minimize costs—without compromising performance. From initial CAD file review to final packaging and global shipping, Shenzhen Honyo Prototype manages every step with precision and accountability.

To ensure seamless project initiation, we support multiple file formats, including STEP, IGES, SolidWorks, and PDF drawings with GD&T callouts. Lead times typically range from 5 to 12 business days, depending on complexity and finishing requirements. We also offer a range of post-processing options such as passivation, electropolishing, bead blasting, and laser engraving to meet industry-specific standards.

Below is an overview of our standard CNC machining capabilities for stainless steel components:

| Parameter | Specification |

|——————————-|———————————————-|

| Material Types | SS 303, 304, 316, 17-4 PH, 440C |

| Tolerance | ±0.005 mm (standard), down to ±0.002 mm |

| Surface Roughness | Ra 0.8 µm (standard), down to Ra 0.2 µm |

| Maximum Work Envelope | 800 x 500 x 400 mm |

| Finishing Options | Passivation, electropolishing, bead blasting, anodizing (for fixtures), laser marking |

| Supported File Formats | STEP, IGES, X_T, SolidWorks, PDF (with GD&T) |

| Quality Standards | ISO 9001:2015 compliant, full inspection reports available |

Starting your project is simple. Send your 3D model or technical drawing to Susan Leo at info@hy-proto.com, and our team will respond within 4 business hours with a detailed quotation, DFM feedback, and estimated turnaround time. We support NDA-protected development and offer real-time project tracking for transparency throughout production.

Partner with Shenzhen Honyo Prototype for CNC-machined stainless steel parts that combine engineering excellence with manufacturing precision. Contact Susan Leo today to begin.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.