Contents

Manufacturing Insight: Make Cnc Router

Manufacturing Insight: CNC Router Technology and Honyo Prototype Capabilities

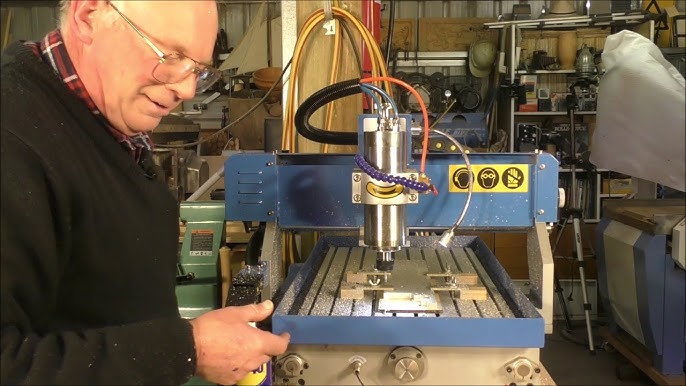

CNC routers represent a cornerstone of modern subtractive manufacturing, translating digital CAD/CAM designs into precise physical components through computer-controlled movement of cutting tools across multiple axes. Unlike milling machines optimized for metals, industrial CNC routers excel at processing softer materials including engineering plastics, composites, wood, foam, and non-ferrous metals like aluminum at high speeds. The core technology relies on rigid gantry structures, high-torque spindles, and sophisticated motion control systems to achieve dimensional accuracy and surface finish critical for functional prototypes and low-volume production parts. Key applications span rapid prototyping of enclosures and fixtures, architectural models, signage, aerospace composite layup molds, and intricate consumer product components where material efficiency and geometric complexity are paramount. Understanding the interplay between machine dynamics, toolpath strategy, and material behavior is essential for maximizing output quality and throughput.

At Shenzhen Honyo Prototype, we leverage industrial-grade CNC routing systems specifically configured for the demanding requirements of engineering prototyping and bridge manufacturing. Our fleet includes machines with reinforced frames and linear guidance systems engineered to maintain exceptional stability during high-speed operations, directly translating to superior edge quality and tight tolerances on intricate features. We prioritize spindle versatility, offering variable speed control from 6,000 to 24,000 RPM to optimize cutting parameters across diverse materials—from delicate acrylics to abrasive carbon fiber reinforced polymers. Our process expertise extends beyond machine operation; our engineering team collaborates closely with clients during the design phase to identify potential manufacturability constraints, recommend material-specific tooling strategies, and implement adaptive toolpaths that minimize vibration and thermal distortion. This proactive approach ensures prototypes not only meet geometric specifications but also accurately reflect the performance characteristics of end-use parts.

Honyo Prototype’s commitment to quality is underpinned by rigorous in-process inspection protocols using calibrated metrology equipment and adherence to ISO 9001 standards throughout our Shenzhen facility. We specialize in transforming complex 3D models into high-fidelity physical assets with rapid turnaround, supporting iterative design cycles essential for product development. The table below outlines the core performance specifications achievable on our primary CNC routing platforms compared to typical industry benchmarks.

| Specification | Honyo Prototype Standard | Industry Typical Range |

| :——————— | :———————– | :——————— |

| Positioning Accuracy | ±0.02 mm | ±0.05 mm – ±0.10 mm |

| Repeatability | ±0.01 mm | ±0.03 mm – ±0.05 mm |

| Max Spindle Power | 9.0 kW | 5.5 kW – 7.5 kW |

| X-Y-Z Travel (mm) | 1300 x 2500 x 300 | 1000 x 2000 x 200 |

| Control System | Siemens SINUMERIK | Mach3 / Basic OEM |

Our integrated manufacturing ecosystem, combining advanced CNC routing capabilities with complementary processes like 3D printing and finishing services, provides clients a single-source solution for accelerating product validation. By maintaining strict control over material selection, machine calibration, and process validation, Honyo Prototype delivers CNC routed components that reliably bridge the gap between digital design intent and real-world functionality, enabling faster time-to-market for innovative products.

Technical Capabilities

CNC Router Manufacturing Capabilities at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype specializes in high-precision CNC machining services, supporting complex fabrication requirements across industries such as aerospace, medical devices, automotive, and consumer electronics. Our advanced CNC router systems are engineered for versatility and accuracy, enabling seamless execution of 3-axis, 4-axis, and 5-axis milling operations, as well as precision turning. These capabilities allow us to produce intricate geometries, tight-tolerance components, and fully finished prototypes or low-volume production parts with consistent repeatability.

Our 3-axis CNC routers provide robust performance for standard milling tasks, ideal for flat or prismatic parts with features aligned to the primary planes. When increased complexity is required, our 4-axis systems introduce rotational capability around the X-axis, enabling machining on multiple faces without manual repositioning. For the most demanding applications, our 5-axis simultaneous CNC routers deliver full contouring precision, allowing tool access from virtually any angle. This is particularly beneficial for organic shapes, undercuts, deep cavities, and highly detailed molds or fixtures.

In addition to multi-axis milling, we integrate precision CNC turning centers to produce cylindrical and rotational components. This hybrid approach ensures that parts requiring both turning and milling operations—such as shafts with keyways or flanged hubs—can be completed in a single setup, minimizing tolerance stack-up and improving overall accuracy.

Tight tolerances are a cornerstone of our manufacturing philosophy. We routinely hold dimensional tolerances down to ±0.005 mm (±0.0002″) for critical features, with surface finishes as fine as Ra 0.8 µm achievable through finishing passes and post-processing options. Our quality control system includes CMM inspection, optical comparators, and laser measurement tools to verify compliance with engineering specifications.

We support a broad range of engineering materials, from metals to engineering plastics and composites. Material selection is optimized based on mechanical requirements, environmental exposure, and functional testing needs.

The table below outlines our standard tolerance ranges and compatible materials:

| Feature | Standard Tolerance | High Precision Capability |

|——–|——————–|—————————-|

| Linear Dimensions | ±0.05 mm | ±0.005 mm |

| Hole Diameter | ±0.025 mm | ±0.01 mm |

| Positional Accuracy | ±0.02 mm | ±0.005 mm |

| Surface Finish (Milling) | Ra 3.2 µm | Ra 0.8 µm |

| Angular Tolerance | ±0.1° | ±0.05° |

| Material Category | Examples |

|——————|———|

| Metals | Aluminum 6061, 7075; Stainless Steel 303, 304, 316; Titanium Grade 2, 5; Brass C360; Tool Steels |

| Plastics | ABS, PC, POM (Delrin), PEEK, Nylon, PMMA (Acrylic), UHMW |

| Composites | Carbon Fiber Reinforced Polymers, G10/FR4, Fiberglass |

At Shenzhen Honyo Prototype, our CNC router capabilities are backed by experienced manufacturing engineers who optimize toolpaths, select appropriate cutting strategies, and oversee process validation to ensure every part meets the highest standards of quality and performance.

From CAD to Part: The Process

From CAD to Precision Part: Honyo Prototype’s CNC Router Production Workflow

At Shenzhen Honyo Prototype, transforming your CAD model into a high-quality CNC router component demands a rigorously defined workflow. This structured process ensures manufacturability, cost efficiency, and adherence to your exact specifications, minimizing delays and rework. Our integrated approach bridges digital design seamlessly to physical realization through three critical, interdependent stages: AI-Powered Quoting, Collaborative DFM, and Precision Production.

The workflow initiates with AI-Powered Quoting. Upon receiving your native CAD file (STEP, IGES, Parasolid), our proprietary AI engine performs an instantaneous, multi-faceted analysis. It deconstructs the geometry to assess geometric complexity, feature density, material requirements, and estimated machine runtime. Crucially, it cross-references this data against our extensive database of material costs, machine capabilities, and historical production metrics. This generates a highly accurate, transparent preliminary quote within hours, not days, providing immediate cost visibility and feasibility insight before formal commitment. This stage eliminates guesswork, setting clear expectations for both parties.

Following quote acceptance, the process advances to Engineer-Led Design for Manufacturability (DFM). This is not an automated check but a value-added engineering review conducted by our senior CNC specialists. They meticulously examine the CAD model, focusing on router-specific constraints: tool access paths, minimum feature sizes relative to cutter diameters, wall thickness stability, optimal stock dimensions, and strategic fixture point placement. We proactively identify potential issues like deep narrow pockets requiring specialized tooling or thin features prone to vibration. Crucially, we provide specific, actionable recommendations for design refinement, collaborating directly with your team to resolve conflicts while preserving your functional intent. This collaborative DFM phase is pivotal for optimizing cycle time, ensuring first-pass yield, and achieving target tolerances reliably.

Only after DFM sign-off does Precision CNC Production commence. Our certified machinists load the approved CAD/CAM program onto state-of-the-art CNC routing centers. Material selection strictly follows your specifications or our DFM-agreed alternatives. Rigorous in-process inspections verify critical dimensions at designated checkpoints. Final parts undergo comprehensive dimensional validation against the original CAD model using calibrated CMMs or structured light scanners, alongside mandatory visual and functional checks. Throughout production, real-time machine monitoring ensures process stability and part consistency. The table below summarizes our core CNC routing capabilities for reference:

| Parameter | Capability Range | Standard Tolerance | Typical Surface Finish (Ra) |

| :—————– | :—————————– | :—————– | :———————— |

| Machine Types | 3-Axis, 4-Axis, 5-Axis Routers | ±0.05 mm | 1.6 – 3.2 µm |

| Max Work Envelope | 3000 x 1500 x 200 mm | ±0.025 mm (Tight) | 0.8 µm (Optimized) |

| Primary Materials | Plastics, Composites, Wood, Soft Metals (Al, Brass) | | |

| Lead Time (Typical)| 3-7 Days (Excl. DFM) | | |

This disciplined workflow – AI Quote enabling speed, Collaborative DFM guaranteeing viability, and Precision Production delivering quality – forms the backbone of Honyo Prototype’s CNC router manufacturing service. We prioritize seamless integration between digital design and physical execution to deliver your parts right-first-time, on schedule, and to exacting standards.

Start Your Project

Start Your CNC Router Project with Precision and Confidence

When it comes to manufacturing high-performance CNC routers, the foundation of success lies in precision engineering, material integrity, and expert collaboration. At Shenzhen Honyo Prototype, we specialize in turning innovative concepts into fully functional, production-ready CNC router systems. Whether you’re developing a desktop model for hobbyist use or an industrial-grade machine for heavy-duty fabrication, our team ensures every component meets exacting standards for accuracy, durability, and performance.

Our CNC machining capabilities are built on advanced 3-, 4-, and 5-axis milling technologies, supported by state-of-the-art CAD/CAM software and rigorous quality control protocols. We work with a wide range of materials, including aerospace-grade aluminum, structural steel, and high-strength composites, to deliver components that meet your mechanical and thermal requirements. From linear rails and spindle mounts to gantry frames and control enclosures, every part is machined to tight tolerances—typically within ±0.005 mm—ensuring seamless integration and optimal machine performance.

We understand that launching a new CNC router project involves more than just machining parts—it requires a partner who can offer technical insight, rapid prototyping, and scalable production solutions. That’s why our engineering team collaborates closely with clients from the initial design phase through final assembly support. We provide Design for Manufacturability (DFM) analysis to optimize part geometry, reduce lead times, and minimize material waste, all while maintaining structural integrity and functional performance.

To streamline your development cycle, we offer fast turnaround times, with prototype components typically delivered within 5–7 business days. Our facility in Shenzhen is equipped for both low-volume prototyping and high-volume production, giving you the flexibility to scale as your project evolves. Surface finishes, heat treatments, and precision threading are available upon request, ensuring your components meet both aesthetic and operational demands.

Below are key specifications for our CNC machining services tailored to CNC router manufacturing:

| Specification | Capability |

|—————————-|————————————————-|

| Machine Types | 3-axis, 4-axis, 5-axis CNC milling |

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Tolerance | ±0.005 mm standard |

| Materials | Aluminum 6061, 7075; Steel 1045, Stainless 304/316; Acetal, PEEK |

| Lead Time (Prototype) | 5–7 days (standard), expedited options available |

| Surface Finishes | As-machined, bead blast, anodizing, powder coat |

| Quality Standards | ISO 9001:2015 compliant, full inspection reports |

Starting your CNC router project with Shenzhen Honyo Prototype means aligning with a partner committed to engineering excellence and on-time delivery. We support global clients with English-speaking project managers, secure data handling, and door-to-door shipping options.

For immediate assistance and a free quote, contact Susan Leo at info@hy-proto.com. Let’s build the next generation of precision CNC machinery—together.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.