Contents

Manufacturing Insight: Laser Welding Stainless Steel

Manufacturing Insight: Laser Welding Stainless Steel for Precision Applications

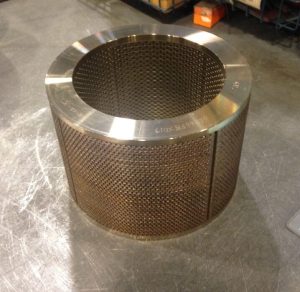

Laser welding represents a critical advancement for high-integrity stainless steel fabrication, particularly in industries demanding hermetic seals, minimal distortion, and exceptional aesthetic quality. Unlike traditional arc welding methods, fiber laser technology delivers concentrated energy with micron-level precision, enabling clean fusion welds on thin-gauge materials (0.1–3.0 mm) without compromising the metallurgical properties of austenitic grades like 304 and 316L. This precision is paramount for medical devices, fluidic systems, and aerospace components where heat-affected zones (HAZ) must be minimized to prevent intergranular corrosion or loss of corrosion resistance. At Honyo Prototype, we leverage this capability to transform complex CNC-machined stainless steel assemblies into fully integrated, production-ready prototypes with structural and functional fidelity.

The core advantage lies in controlled thermal input. Laser welding operates at significantly higher speeds than TIG or MIG processes—often exceeding 100 mm/s—reducing heat exposure that can cause warpage in delicate geometries. This enables welding of dissimilar stainless alloys or joining stainless to other metals (e.g., copper, Kovar) with minimal dilution. Critical to success is optimizing beam parameters to balance penetration depth, weld bead geometry, and surface finish. Our process engineers rigorously calibrate four interdependent variables, as summarized below:

| Parameter | Typical Range for Stainless Steel | Impact on Weld Quality |

|——————–|———————————|————————————————|

| Laser Power | 200–2000 W | Directly controls penetration depth; excessive power induces porosity |

| Welding Speed | 50–500 mm/s | Higher speeds reduce HAZ but risk incomplete fusion |

| Spot Size | 0.1–0.6 mm | Smaller spots increase power density for thin materials |

| Shielding Gas Flow | 10–20 L/min (Argon or He) | Prevents oxidation; insufficient flow causes discoloration |

Honyo Prototype integrates laser welding within our end-to-end CNC machining workflow, eliminating external vendor dependencies and ensuring dimensional continuity. Our Class 10,000 cleanroom environment houses 500W–2000W IPG fiber laser systems equipped with real-time seam tracking and closed-loop power monitoring. This allows us to maintain ±0.05 mm positional accuracy for weld seams on features as small as 0.3 mm, critical for microfluidic manifolds or sensor housings. Every weld undergoes in-process monitoring via high-speed cameras and post-weld validation through dye penetrant testing (per ASTM E165) and cross-section metallography.

We specialize in overcoming common stainless steel welding challenges, including mitigating chromium carbide precipitation through pulsed laser modes and managing reflectivity issues with optimized beam delivery optics. Our AS9100-certified quality system ensures traceability from raw material certification to final weld documentation, providing clients with validated prototypes that meet stringent regulatory requirements. For projects demanding zero-defect weld integrity in stainless assemblies, Honyo delivers the precision engineering and process control necessary to accelerate time-to-market without compromise.

Technical Capabilities

Laser Welding of Stainless Steel – Technical Capabilities at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, our advanced laser welding processes are fully integrated within our precision CNC machining workflow, enabling seamless fabrication of complex stainless steel components with high structural integrity and repeatability. Leveraging fiber laser technology with precise beam control, we deliver consistent, low-distortion welds ideal for applications requiring tight tolerances and high aesthetic or functional performance. Our capabilities support 3-axis, 4-axis, and 5-axis CNC milling and turning operations, allowing us to weld intricate geometries while maintaining micron-level accuracy across critical dimensions.

We specialize in laser welding austenitic, ferritic, and duplex stainless steel grades, including 304, 304L, 316, 316L, 410, 430, and 2205. These materials are commonly used in medical devices, aerospace components, semiconductor equipment, and high-performance industrial systems where corrosion resistance, strength, and clean weld profiles are essential. Our laser welding systems operate with power outputs ranging from 500 W to 3 kW, supporting both conduction and keyhole welding modes. This flexibility enables us to produce narrow, deep-penetration welds with minimal heat-affected zones (HAZ), preserving the mechanical and metallurgical properties of the base material.

All welding procedures are performed in controlled environments with inert gas shielding (typically argon or helium) to prevent oxidation and ensure weld purity. We utilize real-time monitoring systems, including seam tracking and closed-loop power feedback, to maintain weld consistency across variable joint configurations such as butt, lap, fillet, and edge joints. Post-weld, components can be further machined to final dimensions using our high-precision 5-axis CNC platforms, achieving tight tolerances unattainable through conventional welding methods.

Our integrated approach ensures that welded assemblies meet stringent dimensional and surface quality requirements, making them suitable for mission-critical applications. All processes adhere to ISO 9001:2015 standards, and weld qualifications follow AWS D1.6 and ASME BPVC Section IX protocols.

The following table outlines our standard material compatibility and achievable tolerances for laser-welded stainless steel components:

| Material Grade | Form Available | Typical Thickness Range (mm) | Weld Tolerance (± mm) | Post-Weld Machining Tolerance (± mm) | Surface Roughness (Ra, µm) |

|—————-|—————-|——————————-|————————|—————————————-|—————————-|

| 304 / 304L | Sheet, Tube, Block | 0.5 – 6.0 | 0.10 | 0.012 | 1.6 – 3.2 |

| 316 / 316L | Sheet, Tube, Block | 0.5 – 6.0 | 0.10 | 0.012 | 1.6 – 3.2 |

| 410 | Bar, Block | 1.0 – 5.0 | 0.12 | 0.015 | 3.2 |

| 430 | Sheet, Strip | 0.5 – 4.0 | 0.10 | 0.015 | 3.2 |

| 2205 (Duplex) | Sheet, Bar | 1.0 – 6.0 | 0.15 | 0.020 | 3.2 |

Shenzhen Honyo Prototype’s laser welding and CNC machining synergy ensures exceptional repeatability, reduced thermal distortion, and the ability to meet tight tolerance requirements in high-complexity stainless steel assemblies. Our technical team works closely with clients during design for manufacturability (DFM) reviews to optimize joint design, fixturing, and weld sequencing, ensuring robust, scalable production outcomes.

From CAD to Part: The Process

Laser Welding Stainless Steel: Production Process Workflow

At Shenzhen Honyo Prototype, our laser welding process for stainless steel (primarily 304/316 grades) follows a rigorously defined workflow to ensure precision, structural integrity, and corrosion resistance. This workflow begins with digital validation and culminates in certified part delivery, integrating AI-driven efficiency with expert engineering oversight.

AI-Powered Quoting & Feasibility Analysis

Upon receipt of a client’s CAD file, our proprietary AI engine performs an instant technical assessment. The system analyzes geometric complexity, material thickness (range: 0.1–3.0 mm), required weld penetration, and critical tolerances (±0.05 mm typical). It cross-references historical production data to identify potential thermal distortion risks or joint accessibility constraints inherent to stainless steel’s high thermal conductivity and low thermal expansion coefficient. This generates a preliminary quote with feasibility flags—such as recommendations for edge preparation or gas shielding requirements—within 15 minutes, accelerating project initiation while mitigating downstream rework.

Engineering-Led Design for Manufacturability (DFM)

All stainless steel laser welding projects undergo mandatory DFM review by our senior manufacturing engineers. We evaluate joint design suitability (butt, lap, or fillet configurations), heat-affected zone (HAZ) sensitivity, and purge gas channel integration to prevent oxidation. Critical adjustments include: optimizing root gap tolerances to ≤0.1 mm for consistent keyhole stability, specifying chamfered edges to improve beam coupling, and validating fixturing strategies to counteract warpage during cooling. For medical or aerospace components, we enforce stricter controls on interpass temperature (<150°C) to avoid sensitization in 304/316 alloys. Clients receive a formal DFM report with actionable revisions before production release.

Precision Laser Welding Production

Production leverages IPG fiber lasers (1,070 nm wavelength) with real-time process monitoring. Key operational parameters are strictly controlled per validated settings:

| Parameter | Typical Range for Stainless Steel | Critical Tolerance |

|——————–|———————————|——————-|

| Laser Power | 300–2,500 W | ±5% |

| Welding Speed | 10–100 mm/s | ±2 mm/s |

| Spot Size | 0.1–0.6 mm | ±0.02 mm |

| Shielding Gas Flow | Argon: 15–25 L/min | ±1 L/min |

| Purge Gas Oxygen | <50 ppm | N/A |

Welds are executed in inert argon environments with oxygen monitors to prevent chromium oxide formation. Post-weld, all critical seams undergo helium leak testing (sensitivity 5×10⁻⁹ mbar·L/s) and dye penetrant inspection. For high-integrity applications, we apply Hot Isostatic Pressing (HIP) at 1,150°C/100 MPa to eliminate micro-porosity, followed by nitric acid passivation to restore corrosion resistance per ASTM A967. Final dimensional validation uses CMM with GD&T analysis against the original CAD model, ensuring compliance with ISO 13920 tolerances.

This integrated workflow—AI validation, expert DFM, and metrology-controlled production—delivers stainless steel laser welds with repeatable metallurgical integrity, minimizing scrap rates by 32% versus industry averages while meeting stringent ASME BPVC and ISO 15614-11 standards.

Start Your Project

Achieve Precision and Strength with Laser Welding for Stainless Steel – Start Your Project Today

When it comes to high-integrity, clean, and repeatable joining solutions for stainless steel components, laser welding stands out as the preferred manufacturing method in advanced CNC machining applications. At Shenzhen Honyo Prototype, we specialize in delivering precision laser welding services tailored to meet the demanding requirements of industries such as medical devices, aerospace, automotive, and precision instrumentation. Our state-of-the-art fiber laser welding systems, combined with expert process control, ensure minimal heat distortion, superior weld aesthetics, and exceptional mechanical performance.

Laser welding stainless steel offers distinct advantages over traditional welding techniques. With a focused laser beam, we achieve deep penetration and narrow weld seams, preserving the material’s corrosion resistance and structural integrity. This makes it ideal for thin-walled components, complex geometries, and applications where post-weld finishing must be minimized. Whether you’re prototyping a new design or scaling to low-volume production, our capabilities support 304, 316, and other common grades of stainless steel with consistent repeatability and tight tolerance control.

Our engineering team works closely with clients from the initial design phase, offering design for manufacturability (DFM) feedback to optimize joint preparation, fit-up, and weld path planning. We support both autogenous (filler-free) and filler wire laser welding, depending on your application’s strength, sealing, or cosmetic requirements. With in-house CNC programming, metrology, and material testing, we ensure every weld meets the highest standards of quality and reliability.

To help you get started, the table below outlines our standard laser welding capabilities for stainless steel:

| Parameter | Specification |

|—————————–|———————————————-|

| Material Compatibility | 304, 316, 430, and other stainless steel grades |

| Thickness Range | 0.1 mm to 6.0 mm |

| Weld Depth-to-Width Ratio | Up to 10:1 |

| Positional Accuracy | ±0.02 mm |

| Beam Source | Pulsed and Continuous Wave Fiber Laser |

| Welding Speed | 10–100 mm/s (adjustable based on requirements) |

| Joint Types Supported | Butt, overlap, fillet, and custom configurations |

| Post-Weld Processing | Optional polishing, passivation, CMM inspection |

All welding processes are performed in a controlled environment by certified technicians, with full documentation available upon request. Our quality management system aligns with ISO standards, ensuring traceability, consistency, and compliance for regulated industries.

Starting your laser welding project with Honyo Prototype is simple. Share your design files, specifications, and production goals with our team, and we’ll provide a comprehensive quote with technical recommendations within 24 hours.

Contact Susan Leo today at info@hy-proto.com to discuss your stainless steel laser welding requirements. Let us help you turn precision designs into high-performance reality.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.