Contents

Manufacturing Insight: Lathe Metal Turning Tools

Manufacturing Insight: Precision Lathe Metal Turning Capabilities at Honyo Prototype

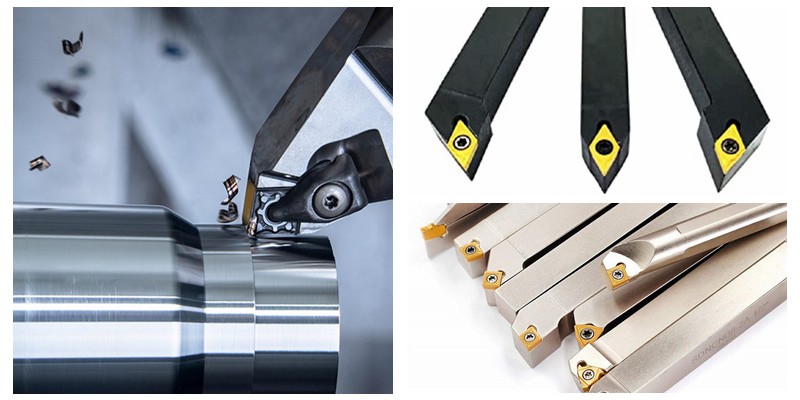

Lathe metal turning remains a cornerstone subtractive manufacturing process for creating precise cylindrical components, shafts, pins, bushings, and complex rotational geometries essential in prototyping and low-volume production. At Shenzhen Honyo Prototype, we integrate advanced CNC turning technology within our broader precision manufacturing ecosystem, specifically designed to complement our core sheet metal fabrication services. This capability ensures clients receive fully integrated assemblies where turned components mate seamlessly with laser-cut, formed, and welded sheet metal structures, eliminating supply chain fragmentation and accelerating time-to-prototype.

Our CNC turning centers deliver exceptional accuracy and surface finish for both ferrous and non-ferrous materials commonly required in functional prototypes and bridge production. We routinely machine aluminum alloys (6061, 7075), stainless steels (303, 304, 316), brass, copper, and engineered plastics. The process utilizes computer-controlled single-point cutting tools that remove material from a rotating workpiece, enabling tight tolerances, intricate features like grooves, threads, and undercuts, and consistent repeatability critical for validation testing and pre-production runs. Honyo’s turning capacity bridges the gap between initial concept models and full-scale manufacturing, providing parts that accurately reflect final production intent in form, fit, and function.

Honyo Prototype’s dedicated turning resources are optimized for the specific demands of rapid prototyping and low-volume precision manufacturing. Key technical specifications are maintained to ensure process capability:

| Parameter | Specification Range | Capability Significance |

| :——————— | :————————— | :—————————————— |

| Max Turning Diameter | Ø 200 mm | Accommodates medium-sized prototype parts |

| Max Bar Capacity | Ø 52 mm | Supports efficient bar-fed production runs |

| Spindle Speed Range | 50 – 6,000 RPM | Optimized for diverse materials & finishes |

| Positional Accuracy | ± 0.005 mm | Ensures critical feature alignment |

| Tool Stations | 8 – 12 (Live Tooling Optional)| Enables complex mill-turn operations |

Rigorous quality control is inherent to our turning process. Every batch undergoes dimensional verification using calibrated micrometers, bore gauges, and surface roughness testers. Critical features on first articles and periodic samples are validated via Coordinate Measuring Machine (CMM) inspection, generating comprehensive reports traceable to client specifications. Our engineers collaborate closely with clients during the Design for Manufacturability (DFM) phase, providing actionable feedback on geometry, tolerances, and material selection to optimize machinability, reduce lead times, and minimize cost without compromising functionality.

By incorporating precision CNC turning alongside our extensive sheet metal capabilities—laser cutting, CNC bending, welding, and finishing—Honyo Prototype offers a truly unified manufacturing solution. This integrated approach eliminates the coordination challenges and quality inconsistencies of managing multiple vendors. Clients benefit from a single point of accountability, streamlined communication, and assemblies where every component, whether formed from sheet or turned from bar stock, meets the stringent requirements of demanding engineering applications. Trust Honyo to deliver the precision-turned elements that complete your next-generation product prototype with speed and reliability.

Technical Capabilities

Lathe Metal Turning Tools – Technical Capabilities

At Shenzhen Honyo Prototype, our expertise in sheet metal fabrication extends to precision lathe metal turning operations, supporting high-integrity components for industrial, automotive, and electronics sectors. While our core competencies include laser cutting, bending, and welding, our lathe turning capabilities are seamlessly integrated to deliver fully machined parts from raw stock to finished product. Our CNC lathe tools are optimized for accuracy, repeatability, and surface finish consistency, ensuring tight alignment with design specifications.

Our lathe turning processes utilize advanced CNC-controlled equipment capable of handling both bar stock and pre-cut blanks. These machines support multi-axis turning, facing, grooving, threading, and drilling operations, enabling complex geometries with minimal manual intervention. All turning operations are performed in climate-controlled environments to minimize thermal variance, enhancing dimensional stability.

We support a wide range of metals commonly used in sheet fabrication and precision machining. Materials are selected based on mechanical requirements, corrosion resistance, and formability. Each material is pre-inspected for grain structure and surface integrity to ensure compatibility with downstream processes such as welding or powder coating.

Tolerances and Material Specifications

The table below outlines the standard tolerances and compatible materials for our lathe turning operations. These values reflect our typical production capabilities under controlled conditions. Tighter tolerances are achievable upon request for critical applications.

| Parameter | Standard Tolerance | Notes |

|——————————-|——————–|——-|

| Diameter Tolerance | ±0.02 mm | Applies to external and internal diameters |

| Length Tolerance | ±0.05 mm | For turned lengths up to 300 mm |

| Concentricity | ≤0.03 mm | Measured over total indicated runout (TIR) |

| Surface Roughness (Ra) | 0.8 – 3.2 µm | Adjustable based on tooling and feed rate |

| Threading Accuracy | Class 6g (metric) | Custom threads available per ISO/DIN standards |

| Material Type | Max Diameter (mm) | Max Length (mm) | Notes |

|——————————-|——————-|—————–|——-|

| Mild Steel (Q235, SS400) | 120 | 500 | Weldable, cost-effective |

| Stainless Steel (304, 316) | 100 | 450 | Corrosion-resistant, non-magnetic (316) |

| Aluminum Alloys (6061, 5052) | 110 | 500 | Lightweight, excellent machinability |

| Brass (C3604) | 90 | 400 | High conductivity, decorative finish |

| Carbon Steel (45#, 20#) | 120 | 500 | Hardened variants available |

All turned components undergo 100% first-article inspection and batch sampling using calibrated CMMs and optical comparators. In-process checks ensure alignment with GD&T callouts and surface requirements. Our quality system is ISO 9001-certified, supporting traceability from raw material to final shipment.

Integration with laser cutting, bending, and MIG/TIG welding allows Honyo to deliver complex assemblies with minimal lead time. For example, a fabricated enclosure with precision shafts can be laser-cut, bent, welded, and machined entirely in-house, reducing handling and improving consistency.

For design optimization, we recommend maintaining uniform wall thicknesses, avoiding sharp internal corners, and specifying critical tolerances only where functionally necessary. Our engineering team provides DFM feedback within 24 hours to support rapid prototyping and production ramp-up.

From CAD to Part: The Process

Lathe Metal Turning Production Workflow: From CAD to Precision Part

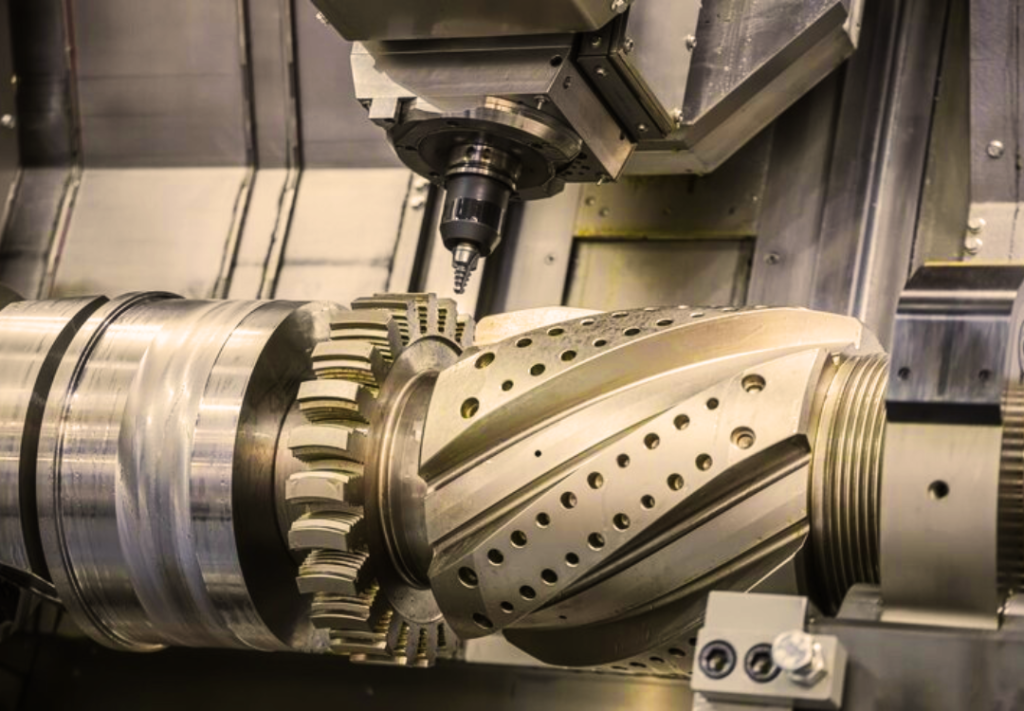

Shenzhen Honyo Prototype executes lathe turning operations for cylindrical components using bar stock or solid blanks, not sheet metal. Our end-to-end workflow ensures precision, efficiency, and adherence to client specifications, spanning three critical phases: AI-Powered Quoting, Collaborative DFM, and Production Execution. This structured approach minimizes iterations and accelerates time-to-part while maintaining rigorous quality standards.

The process initiates with AI-Powered Quoting. Upon receipt of a client’s CAD model (STEP, IGES, or native formats), our proprietary AI system automatically analyzes geometric complexity, material requirements, tolerances, and surface finishes. It cross-references historical production data, machine capabilities, and material costs to generate an instant, data-driven quote within 2 hours. This system identifies potential high-risk features early—such as thin walls, deep grooves, or tight concentricity demands—flagging them for immediate DFM review. Clients receive a transparent cost breakdown, lead time estimate, and preliminary risk assessment, enabling informed project decisions before formal commitment.

Collaborative DFM (Design for Manufacturability) follows quote acceptance. Our engineering team conducts a detailed technical review, focusing on optimizing the design for CNC turning efficiency. We assess toolpath feasibility, chucking stability, and feature sequencing to eliminate unnecessary operations. Critical outputs include actionable suggestions—such as adjusting radii to reduce tool wear, modifying tolerances to standard machining capabilities, or repositioning features to minimize setups. This phase is inherently collaborative; we provide annotated CAD markups and host virtual sessions to align with the client’s functional requirements, ensuring manufacturability without compromising performance. DFM approval is mandatory before production launch, reducing scrap rates by up to 35% based on historical data.

Production Execution commences with CAM programming and rigorous setup validation. G-code is generated using Mastercam, optimized for our HAAS ST-series lathes with live tooling. A first-article inspection (FAI) is performed against the CAD model using CMM and optical comparators, verifying all critical dimensions prior to batch production. Throughout machining, in-process checks monitor key parameters, while final parts undergo 100% dimensional validation and surface roughness testing per ISO 26681. All operations adhere to documented work instructions and real-time SPC tracking.

Key lathe turning capabilities are maintained across our facility to ensure consistency:

| Parameter | Specification Range | Standard Tolerance | Supported Materials |

|——————–|—————————|——————–|———————————–|

| Max. Turning Diameter | 500 mm | ±0.01 mm | Aluminum, Steel, Stainless, Brass |

| Max. Bar Capacity | 76 mm diameter | Surface Ra 1.6 μm | Titanium, Plastics (PEEK, Delrin)|

| Spindle Speed | 50–5000 RPM | Concentricity 0.02 mm | |

| Tooling | 8–12 station live tooling | Runout ≤ 0.005 mm | |

This integrated workflow—from AI-driven quoting through collaborative DFM to precision production—ensures Honyo delivers complex turned components with repeatable accuracy, reduced lead times, and minimized total project risk. Clients benefit from early technical engagement and transparent process control, turning design intent into certified, high-integrity parts.

Start Your Project

Start Your Precision Metal Turning Project with Honyo Prototype

At Shenzhen Honyo Prototype, we specialize in high-precision lathe metal turning services tailored for industries demanding accuracy, repeatability, and rapid turnaround. Whether you’re developing functional prototypes, low-volume production runs, or complex custom components, our advanced CNC turning capabilities ensure your designs are manufactured to exact specifications. Our expertise in sheet metal fabrication extends seamlessly into precision turning, allowing us to deliver fully integrated metal solutions under one roof.

Our state-of-the-art CNC lathes support multi-axis turning operations, enabling us to produce intricate geometries with tight tolerances as close as ±0.005 mm. We work with a wide range of engineering metals including aluminum, stainless steel, brass, copper, and alloy steels, ensuring compatibility with your performance and environmental requirements. From simple shafts to complex threaded components, our machining processes are optimized for efficiency, surface finish quality, and dimensional accuracy.

We understand that every project begins with a vision. That’s why our engineering team collaborates closely with clients during the design phase to identify opportunities for manufacturability improvements, cost optimization, and material selection. By integrating Design for Manufacturability (DFM) analysis early in the process, we minimize production delays and reduce overall project costs—delivering better results, faster.

To get started, simply share your technical drawings, 3D models, or project specifications with our team. We support all major file formats including STEP, IGES, DWG, DXF, and PDF. Once received, our manufacturing engineers will conduct a comprehensive review and provide feedback within 12–24 hours. From quotation to delivery, our streamlined workflow ensures transparency, speed, and consistent quality.

Below is an overview of our standard lathe turning capabilities:

| Parameter | Specification |

|—————————-|——————————————–|

| Maximum Turning Diameter | 300 mm |

| Maximum Turning Length | 500 mm |

| Tolerance | ±0.005 mm (typical) |

| Surface Finish | Ra 0.8 – 3.2 µm (custom finishes available)|

| Spindle Speed | Up to 6,000 RPM |

| Bar Capacity | Up to 51 mm diameter (bar feed option) |

| Materials Supported | Aluminum, Stainless Steel, Brass, Copper, Carbon Steel, Alloy Steel |

| Equipment Types | CNC Swiss Lathes, Multi-Axis Turning Centers, Vertical & Horizontal Lathes |

All components undergo rigorous in-process and final inspections using precision measuring instruments, including CMMs, micrometers, and optical comparators, ensuring compliance with ISO 9001 standards.

Ready to bring your metal turning project to life? Contact Susan Leo, our dedicated Project Coordinator, to discuss your requirements, request a quote, or schedule a technical consultation. At Honyo Prototype, we’re committed to turning your concepts into high-quality, precision-engineered parts—on time and to specification.

Email Susan Leo at info@hy-proto.com to start your project today.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.