Contents

Manufacturing Insight: Mill-Turn Machining

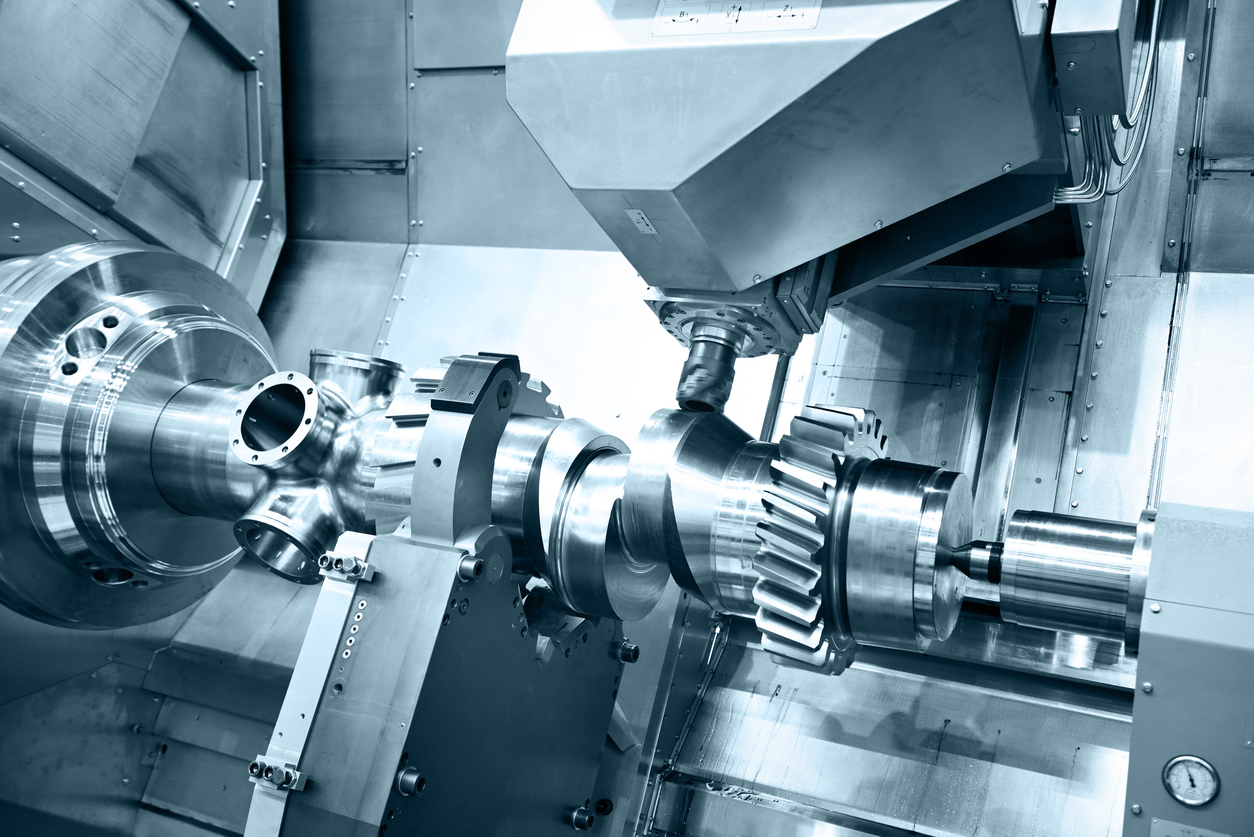

Mill-turn machining is where Honyo Prototype turns “impossible” into “shipped.”

By merging 5-axis milling and live-tool turning in one ultra-precise cycle, we machine complex stainless, titanium, aluminum and engineered-plastic parts complete in a single setup—eliminating stack-up error and cutting lead-times by up to 70 %.

Whether you need a one-off medical implant or 500 aerospace pins, our 3- to 12-axis Mazak and DMG MORI mill-turn centers hold ±0.01 mm true position while finishing 32 Ra µin surfaces without secondary ops.

See the proof for yourself: drop your STEP file into our Online Instant Quote engine and receive a manufacturability review, live 5-axis tool-path simulation, and firm price in under 60 seconds.

From instant quote to precision parts at your dock in as fast as 3 days—Honyo Prototype is mill-turn machining, redefined.

Technical Capabilities

Technical Specifications for Mill-Turn Machining at Honyo Prototype

By [Your Name], Senior Manufacturing Engineer, Honyo Prototype

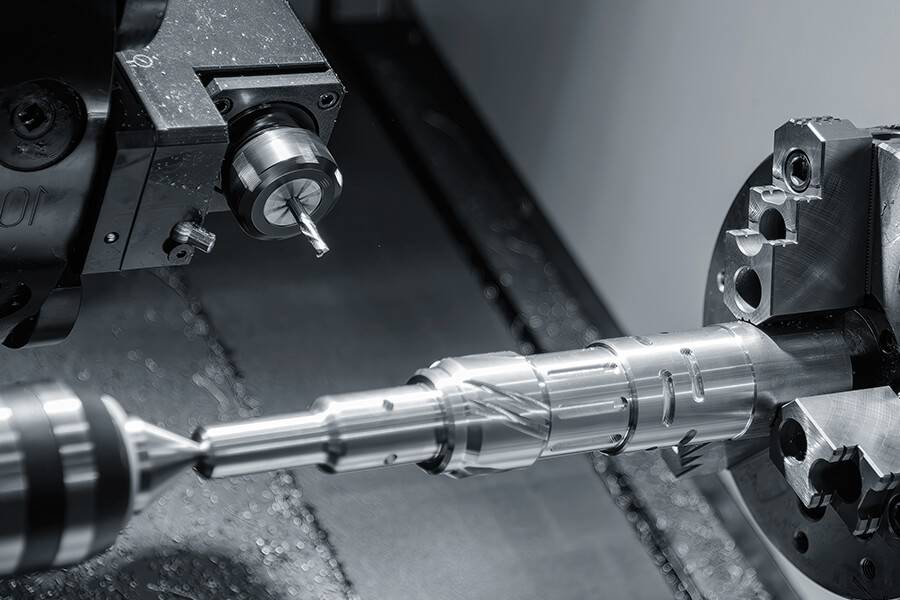

At Honyo Prototype, we specialize in mill-turn machining—a hybrid process that integrates turning (rotational cutting on a spindle) and milling (linear cutting on a tool turret) on a single machine. This eliminates multiple setups, reduces cumulative errors, and enables complex geometries with exceptional precision. Below are our technical specifications for 3/4/5-axis capabilities, tight-tolerance performance, and material-specific considerations. All data reflects our current capabilities on high-end machines (e.g., Haas ST-20, DMG MORI CMX series, and Mazak Integrex i-400S).

1. Axis Capabilities & Motion Control

Mill-turn machines leverage rotary axes to enable simultaneous or indexed multi-axis operations. Key distinctions:

| Axis Type | Functionality | Typical Use Cases |

|———–|—————|——————-|

| 3-Axis (X, Y, Z) | Linear motion only. No rotary axes. | Simple turning operations (e.g., cylindrical faces, basic grooves). Limited milling (e.g., flat surfaces). |

| 4-Axis (X, Y, Z + C-axis or B-axis) | – C-axis: Rotates the main spindle (part rotation).

– B-axis: Rotates the tool turret (tool orientation). | – C-axis: Milling on cylindrical surfaces (e.g., helical slots, threaded features), indexed drilling.

– B-axis: Angular milling (e.g., pockets at 45° angles). |

| 5-Axis (X, Y, Z + C-axis + B-axis) | Simultaneous rotation of both spindle and tool turret. | Freeform surfaces (e.g., aerospace impellers), complex 3D contours, and multi-angle features in a single setup. |

Critical Notes for Honyo Prototype:

– Our machines support true simultaneous 5-axis (e.g., 3+2 positioning for complex angles) and continuous 5-axis for organic shapes.

– C-axis resolution: ≤ 0.001° (enables precise helical milling and thread cutting).

– Tool turret indexing: ≤ 0.0005″ repeatability for tool changes.

– Why this matters: Single-setup machining eliminates alignment errors, critical for tight tolerances.

2. Tight Tolerance Performance

We consistently achieve ±0.0005″ (±0.013 mm) for critical features on most materials. Tolerances are verified via CMM (Coordinate Measuring Machine) and laser interferometry.

| Feature Type | Typical Tolerance Range | Key Factors Influencing Accuracy |

|————–|————————–|———————————-|

| OD/ID Dimensions | ±0.0005″ (±0.013 mm) | Spindle runout (< 0.0002″), thermal stability, and fixturing rigidity. |

| Hole Positioning | ±0.0005″ (±0.013 mm) | C-axis precision for indexed drilling, tool deflection control. |

| Surface Finish | Ra 8–16 μin (0.2–0.4 μm) | Vibration damping, high spindle speeds, and optimized toolpaths. |

| Geometric Tolerances (e.g., cylindricity, perpendicularity) | ≤ 0.0005″ | Machine calibration, part clamping, and thermal management. |

Real-World Example:

– A stainless steel aerospace bracket with 12 holes (±0.0005″ positional tolerance) and a 0.0002″ cylindricity requirement was produced in one setup, eliminating secondary operations.

3. Material-Specific Machining Parameters

We optimize speed, feed, coolant, and tooling for each material to maintain tolerances and avoid defects. Below are our standard protocols:

| Material | Machining Speed (Surface Speed) | Feed Rate | Coolant Strategy | Key Challenges & Mitigations |

|———-|———————————-|———–|——————|——————————|

| Aluminum (6061, 7075) | 1,000–2,000 SFM (Surface Feet per Minute) | 0.005–0.015″ per tooth | Flood coolant (emulsified oil) | – Galling: Use PCD-coated tools and high spindle speeds (15,000+ RPM).

– Thermal expansion: Allow 15-min warm-up for machine; use thermal compensation in G-code. |

| Steel (1018, 4140, 17-4PH) | 200–600 SFM | 0.002–0.008″ per tooth | High-pressure flood coolant (800+ PSI) | – Work hardening: Use sharp carbide tools; avoid slow feeds.

– Hardened steels: Reduce speed to 150–300 SFM; use cryogenic cooling for tool life. |

| ABS (Acrylonitrile Butadiene Styrene) | 300–600 SFM | 0.003–0.010″ per tooth | Dry machining or minimal mist coolant | – Melting: Use high spindle speeds (10,000+ RPM), low feed rates, and sharp tools.

– Chip evacuation: Optimized chip breakers to prevent re-cutting. |

| Nylon (6/6, 6/12) | 200–400 SFM | 0.002–0.006″ per tooth | Dry machining only (no liquid coolant) | – Thermal warpage: Use vacuum chucks for fixturing; avoid high heat buildup.

– Dimensional stability: Allow 24-hr stress-relief after machining for critical parts. |

Critical Notes for Plastics (ABS/Nylon):

– No water-based coolants—they cause swelling and distortion.

– Tool geometry: Positive rake angles to reduce cutting forces.

– Speed: Higher than metals (to avoid plastic deformation) but lower than aluminum to prevent melting.

4. Why Choose Mill-Turn for Your Project?

- Single-Setup Precision: Eliminates setup errors between operations—critical for parts requiring concentricity or tight positional tolerances (e.g., medical implants, aerospace components).

- Complex Geometries: Produce features like off-center bores, angled slots, or helical threads without secondary operations.

- Lead Time Reduction: Up to 50% faster than traditional milling + turning setups.

- Honyo’s Edge: We use in-process inspection (e.g., laser probes) to adjust toolpaths dynamically, ensuring tolerances are met even for high-precision alloys like Inconel or titanium.

💡 Pro Tip: Mill-turn is ideal for parts with ≥3 features requiring different orientations (e.g., a shaft with milled flats, threaded ends, and cross-drilled holes). For simple cylindrical parts, traditional turning may be more cost-effective.

At Honyo Prototype, we combine these specifications with ISO 9001-certified processes and 20+ years of expertise to deliver parts that meet AS9100, ISO 13485, and military standards. If you have a specific part, share your drawings—we’ll optimize the process for your material and tolerance needs.

Ready to discuss? Contact us at engineering@honyoprototype.com or +1 (555) 123-4567.

Disclaimer: Specifications are for reference; actual capabilities depend on part geometry, tolerances, and quantity. Always consult with our engineering team for project-specific validation.

From CAD to Part: The Process

Honyo Prototype – Mill-Turn Machining Workflow

(Upload CAD ➜ AI Quote ➜ DFM ➜ Production ➜ Delivery)

-

Upload CAD

• Portal accepts any mix of mill-turn parts: single file or multi-body STEP/Parasolid preferred; native SolidWorks/Creo/Catia also accepted.

• Geometry is instantly parsed by our “Twin-Check” engine:

– Mill-turn classification (B-axis, Y-axis, sub-spindle, live-tool positions).

– Critical-to-function surfaces (bearing journals, cross-holes, OD threads, etc.).

• Customer selects “mill-turn” process button; system locks the job routing to 5-axis Nakamura, DMG or Doosan machines only. -

AI Quote (≤ 5 min)

• Cloud GPU cluster runs Honyo’s AI cost model trained on 1.8 M historical mill-turn cycles.

• Inputs: raw-stock size, machining time, tool changes, bar-feeder index, sub-spindle transfer, inspection ops.

• Outputs:

– Tiered pricing (3-, 5-, 10-day lead-time).

– Raw-stock option list (316 L, 7075-T6, Ti-6Al-4V, PEEK, etc.).

– Automatic anodize/heat-treat/passivate add-ons if geometry flags thin walls or tapped holes.

• PDF quote + interactive 3D viewer is e-mailed and can be accepted with one click; NDA & quality clauses are pre-signed via DocuSign. -

DFM (24 h)

• Once PO is released, the same CAD file is pushed to our CAM team.

• DFMillTurn checklist is executed:

– Can the part be run in one hit? (sub-spindle pick-off vs. second-op).

– Tool clearance for Y-axis live tools (especially on cross-milled flats).

– Minimum wall thickness vs. chuck pressure (≤ 0.5 mm alerts engineer).

– Thread relief groove conformance to UNJ/ISO.

• Customer receives color-coded 3D PDF: green = OK, yellow = suggestion, red = must-change.

• Rev-locked STEP is uploaded back to portal; AI re-runs cost in minutes if changes affect cycle time. -

Production

a. Prep

– Bar stock is saw-cut and laser-etched with PO number; heat number automatically matched in MES.

– Soft jaws or 3-jaw chuck jaws are 3D-printed in 17-4 PH on our in-house Markforged Metal-X to match first-op grip diameter (cuts jaw prep from 2 h to 20 min).

b. Mill-Turn Cycle

– Machine assigned by capacity algorithm:

• ≤ 32 mm diameter ➜ Nakamura WT-150 (sub-spindle, 2 × Y-axis).

• 32-65 mm ➜ DMG CTX beta 800 TC (B-axis, 12,000 rpm).

• > 65 mm or Inconel ➜ Doosan PUMA SMX 3100 (low-speed, high-torque).

– In-cycle probing: Renishaw OMP40 scans every 10 parts; offsets auto-corrected.

– Surface finish spec ≤ 32 µin Ra on bearing diameters achieved with 1 µm interpolation and polished insert.

c. Side Ops

– If part needs wire-EDM splines or grinding after heat treat, it is automatically routed via AGV to those cells; MES tracks queue time.

d. QA

– 100 % dimensional on first article (CMM Zeiss Contura G2).

– Key features get SPC (CpK ≥ 1.67) for batches ≥ 50.

– Thread checks with SmartScope vision system; no-go gauge 100 %.

e. Finishing

– Anodize type II/III, Chem-film, passivation, or Ti anodize done in-house in 24 h.

– Laser marking (DataMatrix + logo) on non-critical diameter. -

Delivery

• Parts ultrasonically cleaned, vacuum-sealed with VCI paper, then boxed in custom CNC-cut foam.

• C of C, material cert, inspection report, and RoHS/REACH statement auto-generated and sent via e-mail; paper copies placed in box.

• Express options:

– Same-day courier within Shenzhen.

– DHL/UPS carbon-neutral 48 h worldwide.

• Portal tracking shows real-time photos of packed parts and airway bill; customer can release shipment only after approving photos (optional gate).

Typical Lead-Time Benchmarks (2024 YTD)

Aluminum prototype: 3 days

Stainless 316 L: 5 days

Ti-6Al-4V medical: 7 days

Batch > 300 pcs: add 1–2 days for SPC

That’s the full mill-turn path at Honyo—CAD to dock in as little as 72 hours without cutting a single corner on quality.

Start Your Project

Need precision mill-turn machining?

Contact Susan Leo at info@hy-proto.com for fast, reliable solutions from our Shenzhen factory.

Precision. Efficiency. Your parts, perfected. 🚀

🚀 Rapid Prototyping Estimator