Contents

Manufacturing Insight: Peek Plastic Properties

Manufacturing Insight: PEEK Plastic Properties for Precision CNC Machining

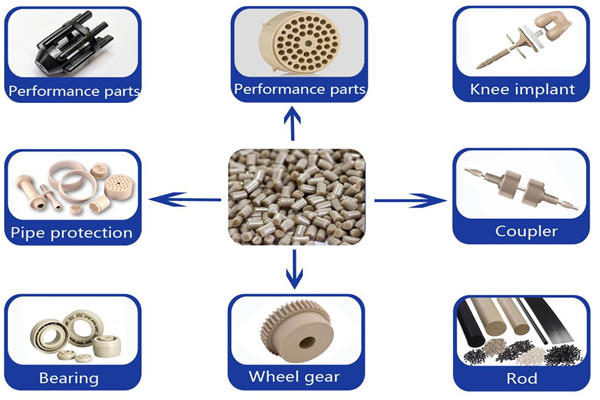

Polyetheretherketone (PEEK) represents a pinnacle engineering thermoplastic for demanding aerospace, medical, and semiconductor applications where conventional polymers fail. At Shenzhen Honyo Prototype, we leverage PEEK’s exceptional thermal stability, mechanical strength, and chemical resistance to deliver mission-critical components via precision CNC machining. Understanding its intrinsic properties is fundamental to overcoming machining challenges and achieving micron-level tolerances consistently. Unlike commodity plastics, PEEK maintains structural integrity under extreme conditions—operating continuously at 250°C while resisting hydrolysis, radiation, and aggressive solvents. This enables components like aircraft bushings, surgical instrument housings, and wafer handling fixtures to perform reliably in sterilization cycles or high-vacuum environments where metal alternatives add unnecessary weight or cost.

Machining PEEK requires specialized process controls due to its semi-crystalline structure and high melting point. Thermal management is critical; excessive heat buildup during cutting can cause localized melting or crystallinity shifts, leading to part distortion. Our CNC protocols utilize rigid toolpaths, cryogenic cooling, and optimized spindle speeds to maintain temperatures below PEEK’s glass transition point (143°C), preventing amorphous phase transitions that compromise dimensional stability. Material hardness necessitates sharp, polished carbide tooling with high rake angles to minimize friction and burr formation—particularly vital for medical-grade surface finishes. Crucially, PEEK’s low thermal conductivity (0.25 W/m·K) demands slower feed rates than metals to dissipate heat, yet its high strength allows aggressive depths of cut compared to softer plastics like PTFE.

We validate all PEEK machining parameters against certified material batches, tracking critical properties through in-house testing. Key specifications guiding our process design include:

| Property | Value | Machining Implication |

|—————————-|——————————-|—————————————–|

| Melting Point | 343°C | Requires low-heat cutting strategies |

| Continuous Service Temp | 250°C | Enables high-temp post-processing |

| Tensile Strength | 90-100 MPa | Allows thin-wall features (<0.5mm) |

| Moisture Absorption (24h) | 0.5% | Mandates pre-drying to <0.02% RH |

| Coefficient of Friction | 0.24 (vs. steel) | Reduces tool wear vs. glass-filled PEEK |

Honyo Prototype’s CNC workflow integrates material science with precision engineering. All PEEK stock undergoes 48-hour vacuum drying at 150°C prior to machining, eliminating moisture-induced voids during processing. Our 5-axis Haas and DMG MORI centers employ real-time thermal compensation algorithms, while in-process CMM verification ensures features like threaded inserts or sealing surfaces hold ±0.025mm tolerances. Post-machining, we offer stress-relief annealing cycles calibrated to PEEK’s crystallization kinetics, preventing long-term warpage in critical assemblies.

For clients requiring FDA-compliant or aerospace-grade PEEK components, our AS9100-certified facility provides full traceability from raw pellet to finished part—including ULTEM 1000, Victrex 450G, and carbon-fiber-reinforced variants. By mastering the interplay between PEEK’s polymer physics and CNC dynamics, Honyo Prototype transforms this high-performance material into components that meet the uncompromising demands of next-generation engineering. Contact our applications team to discuss material selection and process optimization for your specific use case.

Technical Capabilities

PEEK Plastic Properties and CNC Machining Capabilities at Shenzhen Honyo Prototype

Polyetheretherketone (PEEK) is a high-performance thermoplastic widely used in industries requiring exceptional mechanical strength, thermal stability, and chemical resistance. At Shenzhen Honyo Prototype, we specialize in precision CNC machining of PEEK components using advanced 3, 4, and 5-axis milling systems, as well as CNC turning centers. Our manufacturing processes are optimized to maintain the intrinsic material properties of PEEK while achieving tight tolerances and superior surface finishes, making our solutions ideal for aerospace, medical, semiconductor, and oil & gas applications.

PEEK offers a unique combination of properties, including a continuous use temperature up to 250°C, excellent wear resistance, low coefficient of friction, and outstanding resistance to hydrolysis and a broad range of chemicals. Its high strength-to-weight ratio and inherent flame retardancy further enhance its suitability for mission-critical components. However, due to its high melting point and low thermal conductivity, machining PEEK requires precise control of cutting parameters, tool selection, and thermal management to prevent material degradation or dimensional instability.

Our CNC machining capabilities are engineered to meet these challenges. We utilize carbide and diamond-coated tools optimized for high-temperature polymers, along with controlled feed rates and spindle speeds to minimize heat buildup. Our 5-axis milling platforms enable complex geometries to be machined in a single setup, reducing cumulative tolerances and improving accuracy. For rotational parts, our precision turning centers ensure concentricity and surface integrity, critical for sealing surfaces and bearing components.

We maintain stringent environmental controls in our machining areas to ensure stable thermal conditions, minimizing the risk of part warpage due to residual stresses. Additionally, our post-machining inspection protocols include CMM (Coordinate Measuring Machine) verification and surface profilometry to confirm compliance with design specifications.

The following table outlines the material specifications and achievable tolerances for PEEK during CNC machining at Shenzhen Honyo Prototype:

| Material Property | PEEK Natural (Neat) | Units |

|——————-|———————|——-|

| Tensile Strength | 90–100 | MPa |

| Flexural Strength | 140–170 | MPa |

| Heat Deflection Temperature (HDT) | 143–160 | °C |

| Continuous Use Temperature | 250 | °C |

| Density | 1.30–1.32 | g/cm³ |

| Moisture Absorption (24 hrs) | 0.1–0.4 | % |

| Machining Capability | Typical Tolerance | Units |

|————————|——————|——-|

| Linear Dimensions (Milling) | ±0.025 | mm |

| Linear Dimensions (Turning) | ±0.020 | mm |

| Geometric Tolerances (Flatness, Perpendicularity) | ±0.03 | mm |

| Hole Diameter (Drilled) | ±0.025 | mm |

| Surface Roughness (Ra) | 0.8–3.2 | μm |

At Shenzhen Honyo Prototype, we combine advanced CNC technology with in-depth material expertise to deliver PEEK components that meet the most demanding engineering requirements. Our focus on process repeatability and quality assurance ensures consistent performance across prototypes and low-volume production runs.

From CAD to Part: The Process

PEEK CNC Machining Production Workflow: From CAD to Precision Part

At Shenzhen Honyo Prototype, machining polyether ether ketone (PEEK) demands a rigorously controlled workflow due to its high-performance properties and thermal sensitivity. PEEK’s low thermal conductivity, high melting point (343°C), and propensity for residual stress require specialized handling from initial quotation through final production. Our end-to-end process ensures dimensional stability and material integrity, critical for aerospace, medical, and semiconductor applications where PEEK excels.

The workflow begins with AI-Powered Quoting, where uploaded CAD files undergo automated analysis. Our system cross-references PEEK’s unique properties—density (1.32 g/cm³), tensile strength (90–100 MPa), and thermal expansion coefficient (42 × 10⁻⁶/K)—against machine capabilities and material costs. Unlike standard plastics, PEEK’s raw material cost ($50–$100/kg) and extended machining cycles directly impact lead time and pricing. The AI engine flags complex geometries requiring multi-axis setups or slow feed rates to prevent thermal degradation, generating a transparent, data-driven quote within 2 hours.

Next, Design for Manufacturability (DFM) Review focuses exclusively on PEEK’s constraints. Engineers validate wall thickness uniformity to avoid sink marks during cooling, confirm adequate draft angles for stress-free ejection, and assess feature accessibility given PEEK’s tendency to gall with standard tooling. Critical parameters are non-negotiable:

| Parameter | Critical Value for PEEK | Standard Plastic Comparison |

|——————–|————————-|—————————–|

| Max Cutting Speed | 80–120 m/min | 200–300 m/min (e.g., ABS) |

| Clamping Force | ≤ 15 kN (distributed) | ≤ 30 kN (e.g., PP) |

| Coolant Requirement| Dry air or minimal mist | Flood coolant acceptable |

| Annealing Cycle | Mandatory (180°C, 4 hrs)| Rarely required |

DFM adjustments often include adding stress-relief radii or splitting complex parts to minimize fixturing-induced distortion. Only after client sign-off on DFM recommendations does production commence.

Precision Production executes under strict environmental controls. PEEK blanks undergo pre-machining annealing to relieve internal stresses. CNC operations use carbide tools with polished flutes and positive rake angles to reduce heat buildup, paired with low spindle speeds (4,000–6,000 RPM) and high-pressure air evacuation to prevent melting. In-process metrology checks critical dimensions at 25% and 75% completion stages, compensating for PEEK’s 0.2–0.5% post-machining shrinkage. Final parts undergo stress-relief annealing at 180°C for 4 hours, followed by CMM validation against GD&T callouts. Throughout this phase, humidity is maintained below 40% RH to prevent moisture absorption, which compromises PEEK’s mechanical properties.

Shenzhen Honyo Prototype’s integrated workflow—leveraging AI quoting, PEEK-specific DFM rigor, and thermally managed production—delivers parts meeting ISO 2768-mK tolerances consistently. This disciplined approach mitigates PEEK’s machining challenges, transforming high-risk designs into reliable components for mission-critical industries.

Start Your Project

Unlock Precision with PEEK Plastic in CNC Machining

When it comes to high-performance thermoplastics in CNC machining, few materials match the exceptional properties of Polyetheretherketone (PEEK). At Shenzhen Honyo Prototype, we specialize in precision machining of PEEK components for industries where reliability under extreme conditions is non-negotiable. From aerospace to medical devices and semiconductor equipment, PEEK delivers unmatched performance. Understanding its properties is the first step toward optimizing your next engineering project.

PEEK is a semi-crystalline thermoplastic known for its outstanding thermal stability, mechanical strength, and chemical resistance. It maintains structural integrity at continuous operating temperatures up to 250°C (482°F), making it ideal for high-temperature environments where conventional plastics would fail. Its low coefficient of friction and excellent wear resistance also make it a preferred choice for dynamic applications involving repeated motion or contact.

One of the most compelling advantages of PEEK is its ability to resist a broad range of chemicals, including concentrated acids, hydrocarbons, and steam. This resistance, combined with its inherent flame retardancy and low smoke emission, ensures compliance with stringent safety standards in critical applications. Additionally, PEEK offers excellent dimensional stability and low moisture absorption, ensuring consistent performance even in humid or submerged conditions.

For CNC machining, PEEK presents unique challenges due to its high melting point and toughness. However, with the right tooling, cutting parameters, and expertise, it can be machined to tight tolerances with excellent surface finishes. At Honyo Prototype, our team employs advanced CNC techniques and rigorous process controls to ensure every PEEK component meets exact specifications.

Below is a summary of key mechanical and thermal properties of unfilled PEEK commonly used in precision machining:

| Property | Value | Unit |

|——–|——-|——|

| Density | 1.30–1.32 | g/cm³ |

| Tensile Strength | 90–100 | MPa |

| Flexural Strength | 140–170 | MPa |

| Heat Deflection Temperature (HDT) | 149–160 | °C @ 1.82 MPa |

| Continuous Use Temperature | 250 | °C |

| Coefficient of Thermal Expansion | 4.5–5.5 | µm/m·K |

| Moisture Absorption (24h) | 0.2–0.4 | % |

Whether you’re prototyping a new medical implant or developing durable components for industrial automation, selecting the right material is only half the equation. Partnering with a manufacturer who understands the nuances of PEEK machining is equally critical.

Ready to bring your design to life with high-performance PEEK components? Contact Susan Leo at Shenzhen Honyo Prototype today. With our technical expertise and commitment to quality, we ensure your project moves from concept to reality with precision and speed.

Email Susan Leo at info@hy-proto.com to discuss your requirements, request a quote, or receive material recommendations tailored to your application. Let us help you leverage the full potential of PEEK in your next CNC machining project.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.