Contents

Manufacturing Insight: Precision Turning

Precision Turning, Perfected by Honyo

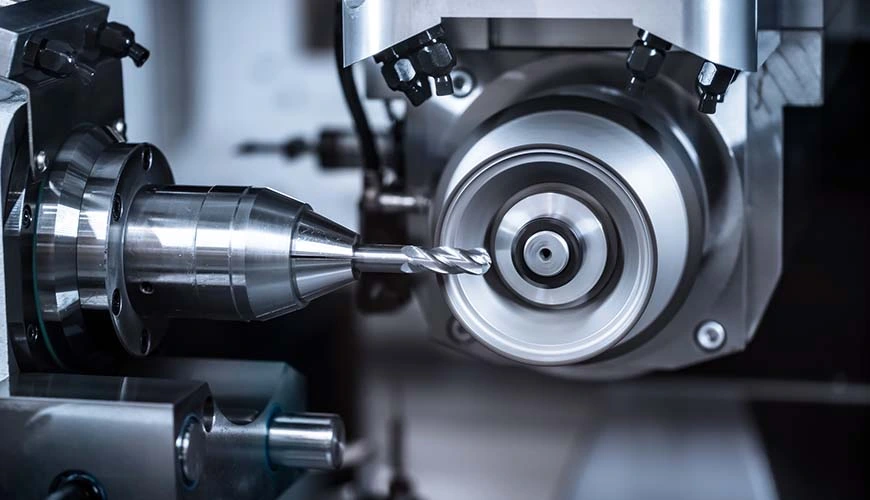

When your design calls for micron-level concentricity and mirror finishes, Honyo’s CNC precision turning centers deliver. We run 3- to 9-axis Citizen and Star Swiss-type lathes with live tooling, bar-fed automation, and on-machine probing that holds ±0.005 mm on even the most complex medical, aerospace, and robotics components. From prototype lot to 50 k-piece production, every part is programmed, machined, and inspected under our ISO 9001 & IATF 16949 systems—no exceptions, no surprises.

Need numbers today? Upload your STEP or drawing to our Online Instant Quote engine; see real-time pricing, lead-time, and DFM feedback in under 60 seconds, then click to order. Precision turning starts here, ships in as fast as 3 days, and lands on your bench ready for assembly.

Technical Capabilities

Precision Machining Specifications Clarification & Technical Details

(Important Note: “Precision Turning” is a distinct process from milling. Your query mixes terminology—turning is a lathe-based process for cylindrical parts, while 3/4/5-axis milling is a separate milling process for complex 3D geometries. As a Senior Manufacturing Engineer at Honyo Prototype, I must clarify this upfront to ensure accurate specifications for your project.)

🔧 I. Precision Turning (Lathe-Based Process)

Only uses rotational motion (X/Z axes) for cylindrical parts. Does NOT involve multi-axis milling. Live tooling (e.g., milling/drilling on a lathe) adds limited milling capability but remains fundamentally a turning process.

| Parameter | Standard Capability | Precision Capability | Notes |

|————————|——————————-|——————————-|—————————————————————————|

| Axes | 2-axis (X, Z) | 3-axis (X, Z + live tooling) | Live tooling allows milling/drilling on-turn, but NOT 4/5-axis milling. True 5-axis milling requires a dedicated mill. |

| Tolerance (General)| ±0.001″ (±0.025 mm) | ±0.0005″ (±0.013 mm) | Achievable with precision tooling, CNC control, and environmental control. |

| Tolerance (Ultra-Precision) | — | ±0.0001″ (±0.0025 mm) | Requires specialized equipment (e.g., sub-micron grinders), vibration isolation, and temperature-controlled environment. |

| Surface Finish | Ra 32–64 μin (0.8–1.6 μm) | Ra 8–16 μin (0.2–0.4 μm) | Mirror finishes (Ra < 4 μin) possible with honing/polishing post-processing. |

| Roundness/Taper | ≤0.001″ TIR | ≤0.0002″ TIR | Measured via CMM or optical comparator. |

| Material-Specific Notes | | | |

| Aluminum | Excellent machinability. Tolerances easily held at ±0.0005″. | Minimal tool wear; use carbide tools with high-speed cutting. | Avoid chatter with rigid setups. |

| Steel (e.g., 1018, 4140, 17-4PH) | Requires coolant for heat control. Tolerances ±0.0005″ achievable. | Hardened steels need pre-heat treatment; grinding often required for ±0.0001″. | Carbide or ceramic tools; avoid excessive speeds. |

| ABS/Nylon | Not recommended for precision turning. High risk of chatter, melting, and dimensional drift due to thermal expansion. | — | Plastics are typically milled (not turned) for complex shapes. If turning is unavoidable, use slow speeds, sharp tools, and no coolant. |

⚠️ Critical Clarification:

– 5-axis milling is NOT part of turning. A “turning center” with live tooling may perform some milling operations (e.g., drilling, slotting), but it is limited to 3-axis (X, Z, C-axis rotation). True 5-axis milling requires a dedicated milling machine.

– ABS/Nylon are rarely turned due to their thermal properties. They are best suited for milling operations (see Section II).

⚙️ II. 3/4/5-Axis Milling (Dedicated Milling Process)

For complex 3D geometries, non-cylindrical parts, and features requiring multi-directional cutting. This is separate from turning.**

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling |

|————————|——————————-|——————————-|——————————-|

| Axes | X, Y, Z (linear) | X, Y, Z + A-axis (rotation) | X, Y, Z + A + B/C-axis (full rotation) |

| Tolerance (General)| ±0.001″ (±0.025 mm) | ±0.001″ (±0.025 mm) | ±0.0005″ (±0.013 mm) |

| Tolerance (Ultra-Precision) | — | — | ±0.0001″ (±0.0025 mm) (with in-process probing & thermal compensation) |

| Surface Finish | Ra 32–64 μin (0.8–1.6 μm) | Ra 16–32 μin (0.4–0.8 μm) | Ra 8–16 μin (0.2–0.4 μm) |

| Complexity | Simple prismatic parts | Parts requiring rotation (e.g., turbine blades) | Freeform surfaces, complex contours, single-setup parts |

| Material-Specific Notes | | | |

| Aluminum | High-speed cutting (1,000+ SFM); carbide tools. Tolerances easily held at ±0.0005″. | Same as 3-axis; 4th axis enables complex pocketing. | 5-axis enables efficient machining of aerospace components (e.g., impellers). |

| Steel (e.g., 4140, 17-4PH) | Requires coolant; slower speeds. Hardened steel needs grinding for tight tolerances. | 4-axis allows angled features without re-fixturing. | 5-axis minimizes tool deflection on deep cavities; critical for mold-making. |

| ABS/Nylon | Best suited for milling. Use high-speed, low-feed rates; dry cutting or air blast. Avoid heat buildup (melting risk). | 4-axis enables undercut features. | 5-axis excels for thin-walled plastic parts (e.g., medical housings) with minimal deflection. |

💡 Key Takeaways for Honyo Prototype Projects

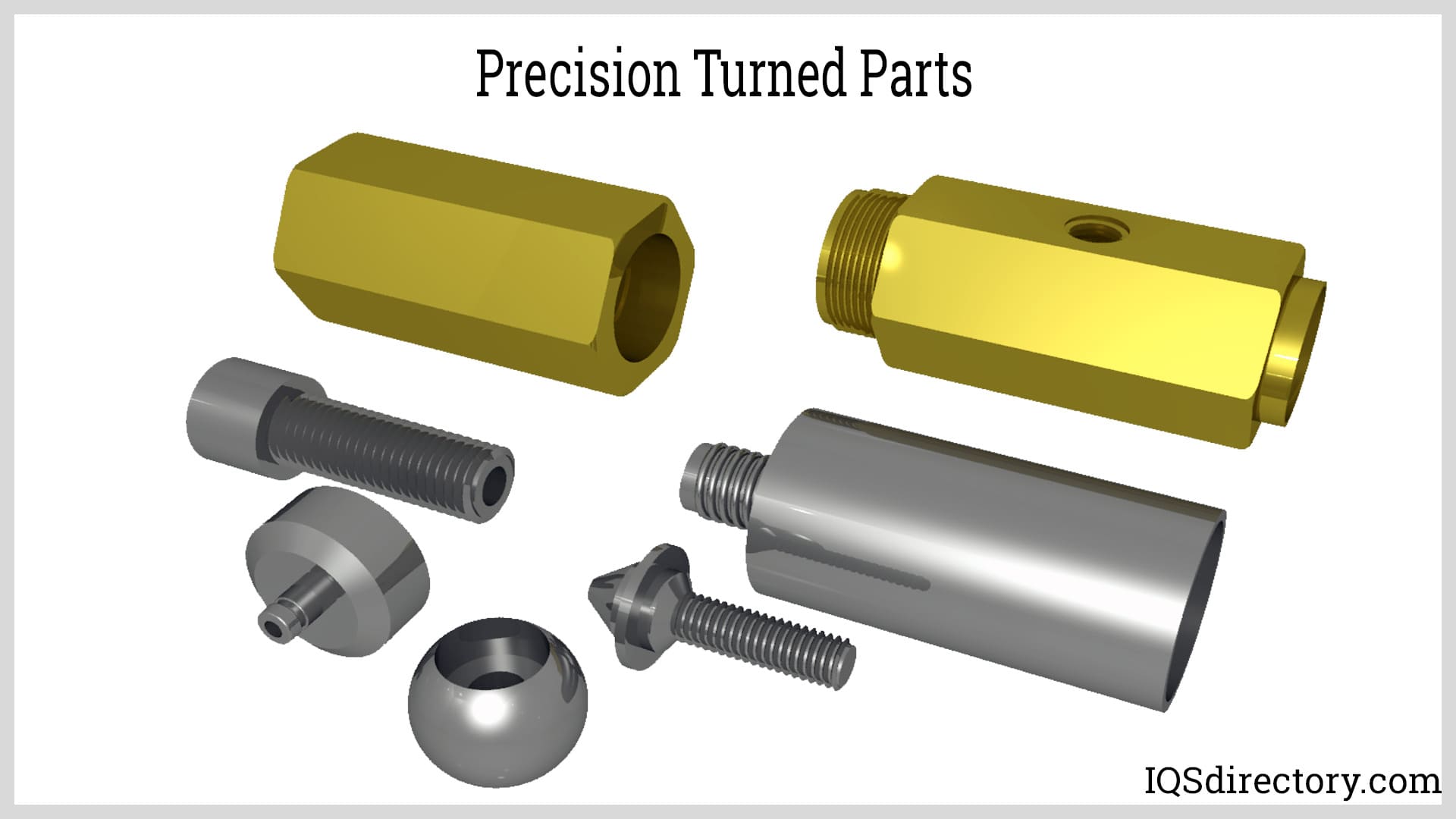

- Turning vs. Milling:

- Use turning for cylindrical parts (shafts, bushings, fittings).

- Use milling for non-cylindrical, complex 3D geometries (e.g., brackets, molds, aerospace components).

-

5-axis milling is exclusively for milling machines—it cannot be performed on a lathe.

-

Tight Tolerance Realities:

- ±0.0005″ (±0.013 mm) is standard for precision work in both processes.

-

±0.0001″ (±0.0025 mm) requires specialized equipment (e.g., sub-micron grinders, CMMs with laser tracking), environmental controls (20°C ±1°C), and is typically only feasible for metals (not plastics like ABS/Nylon).

-

Plastics (ABS/Nylon):

- Never recommend precision turning—thermal expansion causes dimensional drift.

-

Milling is ideal, but requires:

- Sharp, polished tools (e.g., single-flute carbide).

- Low feed rates (50–100 IPM), high spindle speeds (10,000–20,000 RPM).

- No coolant (use air blast to prevent melting).

- Fixturing with minimal clamping force to avoid warpage.

-

Honyo Prototype’s Expertise:

- We specialize in both processes with advanced capabilities:

- Turning: 2/3-axis lathes (e.g., DMG MORI CTX beta series) for ±0.0005″ tolerances.

- Milling: 3/4/5-axis mills (e.g., DMG MORI CTX 500, Haas UMC-750) for ±0.0005″ tolerances on metals; ±0.001″ on plastics.

- Ultra-precision work (±0.0001″) is reserved for critical aerospace/medical components and requires dedicated metrology (e.g., Zeiss CMMs).

📌 Recommendation: Share your part CAD file and functional requirements. We’ll advise the optimal process (turning vs. milling) and specify achievable tolerances for your materials. Never assume “precision turning” includes milling axes—this is a common misconception that leads to incorrect quoting.

Let’s discuss your specific project—contact us for a free DFMA (Design for Manufacturing & Assembly) review. 🔧✨

From CAD to Part: The Process

Honyo Prototype – Precision-Turned Part Workflow

(Round-bar ≤ 42 mm, ≤ 250 mm long, 0.01 mm tolerance, 1–1 000 pcs)

-

Upload CAD

• Web portal or e-mail – STEP, IGES, SolidWorks, Creo, Inventor, Parasolid.

• Auto-validator checks for missing threads, undercuts, GD&T call-outs; instant e-mail confirmation with project #. -

AI Quote (≤ 5 min)

• Neural-net cost model trained on 1.2 M historical jobs; inputs: volume, L/D ratio, tolerance bands, surface finish, secondary ops (cross-hole, knurl, anodise).

• Output: unit price, batch price curve, 3 delivery tiers (3, 5, 7 days), raw-material option list (12L14, 303, 6061-T6, POM, PEEK, etc.).

• One-click accept converts quote into manufacturing packet. -

DFM (same day)

• CAM engineer opens packet; AI pre-positions 80 % of tool-paths.

• Human review:

– Chucking sequence & soft-jaw print (minimise distortion ≤ 0.005 mm).

– Tool-life matrix (insert grade, coating, cutting speed vs. batch size).

– Geometric stack-up check—if tolerance ≤ 0.01 mm, live-tooling or post-grind flagged.

• PDF + interactive 3D e-signed by customer before 16:00 China time → production slot locked. -

Production (lights-out cell)

a. Raw material: 3 m bars laser-measured for diameter variance; auto-fed into Star SR-38J (7-axis) or Tsugami B0326 (with synchro-spindle).

b. In-cycle checks: Renishaw Equator gauging every 10th part; data streamed to SPC dashboard; auto-offset if Cpk < 1.67.

c. Secondary ops (if quoted): cross-drill/tap on Brother Speedio, roller burnish 0.2 µm Ra, or OD centre-less grind to ±0.002 mm.

d. Surface finish: passivation, anodise Type II/III, electroless nickel, or Teflon coat; all lot-controlled via barcode. -

Delivery

• Parts ultrasonically cleaned, vacuum-sealed with VCI paper; CMM report & material cert packed in box.

• DHL/UPS/FedEx pre-cleared; most Asian sites next-day, EU & US 2–3 days door-to-door.

• Digital twin file archived 7 years for instant repeat orders.

Result: repeatable ±0.01 mm turned parts, quoted in minutes, shipped in days, with full traceability from CAD to dock.

Start Your Project

Precision Turning Services by Honyo Prototype | Shenzhen Factory | Contact Susan Leo: info@hy-proto.com

(Clean, professional, and action-oriented—ideal for websites, brochures, or ads. Highlights expertise, location, and direct contact for quick engagement.)

🚀 Rapid Prototyping Estimator