Contents

Manufacturing Insight: Precision Turning

Manufacturing Insight: Precision Turning at Honyo Prototype

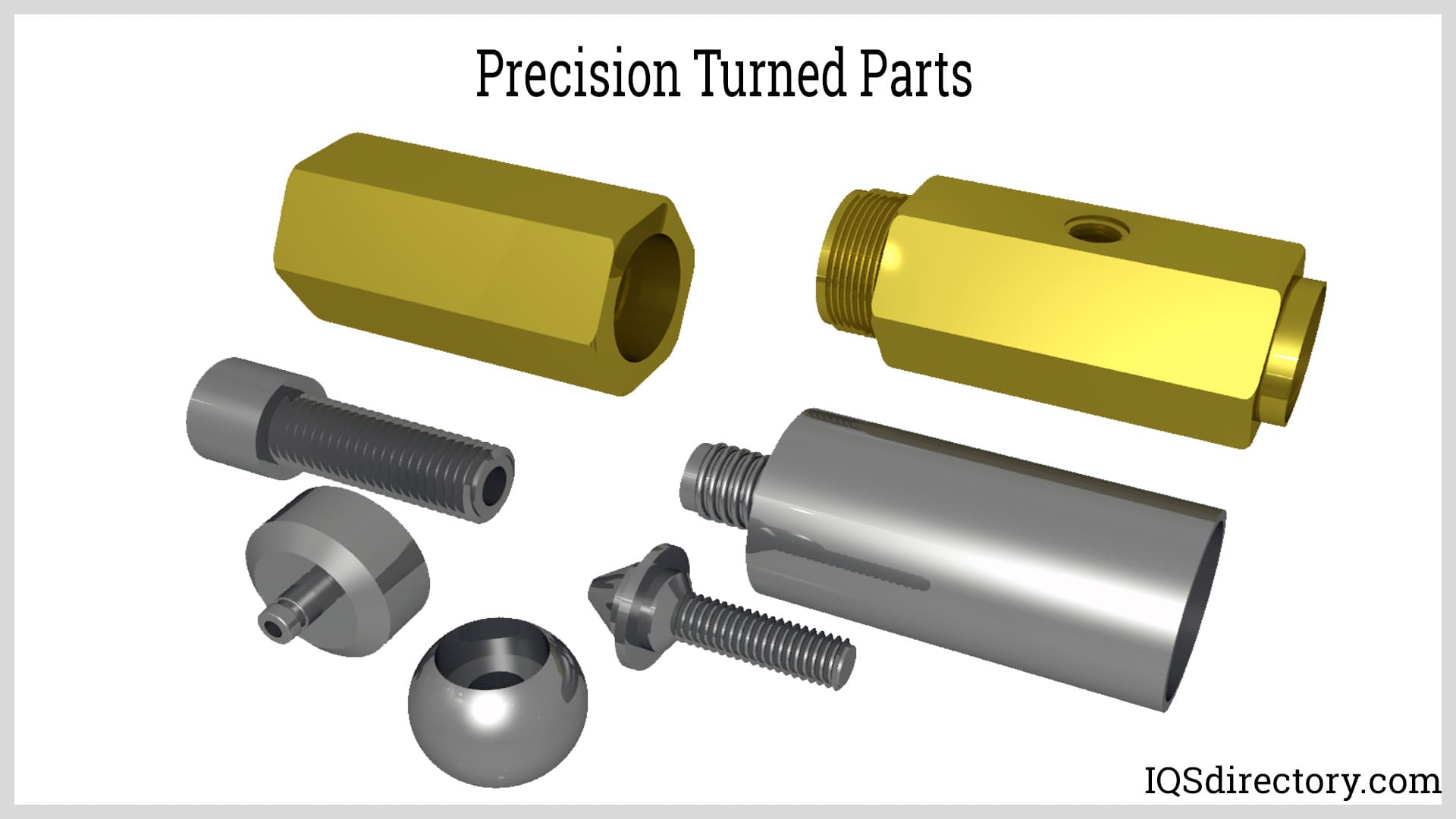

Precision turning represents a cornerstone of high-integrity CNC machining, enabling the production of complex cylindrical components with exceptional geometric accuracy and surface integrity. At Shenzhen Honyo Prototype, this process leverages advanced multi-axis CNC lathes and Swiss-type automatics to transform raw materials into mission-critical parts for aerospace, medical, and industrial automation sectors. Unlike conventional turning, precision turning demands sub-micron level control over dimensional tolerances, surface finishes, and material properties—requirements we systematically exceed through integrated process engineering and real-time metrology.

Honyo Prototype’s capabilities center on tight-tolerance machining of challenging materials including titanium alloys, Inconel, hardened steels, and engineered plastics. Our facility utilizes live-tooling lathes with Y-axis functionality and sub-spindles to perform milling, drilling, and threading operations in a single setup, eliminating cumulative errors from part repositioning. This approach ensures concentricity tolerances as tight as ±0.005 mm and surface finishes down to Ra 0.4 μm, critical for hydraulic components, surgical instruments, and optical mounts. We prioritize rapid prototyping agility without sacrificing repeatability, supporting low-volume production runs from 1 to 500 units with accelerated lead times.

Quality assurance is embedded at every phase through in-process probing and post-machining validation using coordinate measuring machines (CMMs) and optical comparators. Statistical process control (SPC) monitors critical parameters like tool wear and thermal drift, ensuring first-article compliance with ISO 2768-mK and customer-specific standards. Our engineers collaborate with clients during Design for Manufacturability (DFM) reviews to optimize geometry, reduce cycle times, and preempt material-related challenges such as chatter or deformation.

The following table summarizes Honyo’s precision turning specifications for prototyping and low-volume production:

| Parameter | Capability Range | Standard Tolerance |

|————————-|————————————–|——————–|

| Max Turning Diameter | 2 mm – 320 mm | — |

| Max Bar Feed Diameter | 20 mm – 42 mm (Swiss-type) | — |

| Positional Accuracy | — | ±0.003 mm |

| Surface Roughness (Ra) | 0.2 μm – 3.2 μm | Ra 0.8 μm |

| Materials | Steel, Aluminum, Brass, Titanium, PEEK, Inconel | — |

| Lead Time (Prototype) | 3–7 working days (complex geometries) | — |

Honyo Prototype bridges the gap between design ambition and manufacturable reality by combining cutting-edge hardware with deep process expertise. Our precision turning services deliver components that meet stringent functional requirements while accelerating time-to-market for innovative products. Partner with us to transform engineering concepts into high-performance parts where every micron matters.

Technical Capabilities

Precision Turning Capabilities at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype delivers advanced precision turning services as part of our comprehensive CNC machining portfolio. Our expertise in 3, 4, and 5-axis milling combined with high-accuracy turning enables the production of complex, high-integrity components for industries including aerospace, medical, automation, and industrial equipment. We specialize in small to medium batch production, rapid prototyping, and low-volume manufacturing, ensuring tight tolerances and repeatable quality across diverse materials.

Our precision turning centers are equipped with live tooling and Y-axis capabilities, enabling mill-turn operations that integrate rotational and multi-axis milling processes in a single setup. This reduces part handling, minimizes cumulative errors, and enhances geometric accuracy. Our 4-axis and 5-axis milling-turning machines support simultaneous multi-directional cutting, ideal for components requiring off-center features, intricate contours, and complex hole patterns.

We maintain tight control over dimensional accuracy through in-process inspection, tool wear compensation, and thermally stable machining environments. Our quality assurance protocols comply with ISO 9001 standards, and all critical dimensions are verified using CMMs, optical comparators, and laser measurement systems.

Below is an overview of our standard precision turning capabilities, including achievable tolerances and compatible materials.

| Feature | Specification |

|——–|—————|

| Turning Diameter Range | Ø2 mm – Ø300 mm |

| Maximum Turning Length | 500 mm |

| Axis Configurations | 2-axis (CNC Turning), Mill-Turn (3, 4, 5-axis) |

| Spindle Speed | Up to 8,000 RPM (live tooling) |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Surface Finish (Typical) | Ra 0.8 µm (as-machined), down to Ra 0.2 µm with polishing |

| Lead Time (Typical) | 5–12 days, based on complexity and volume |

| Tolerance Class | Dimensional Tolerance | Geometric Tolerance (Runout, Position) |

|—————–|————————|—————————————-|

| Standard | ±0.01 mm | ±0.02 mm |

| Precision | ±0.005 mm | ±0.01 mm |

| High Precision (Tight Tolerance) | ±0.002 mm | ±0.005 mm |

| Material Category | Examples | Notes |

|——————-|———|——-|

| Aluminum Alloys | 6061, 7075, 2024, 5052 | High machinability, ideal for lightweight components |

| Stainless Steels | 303, 304, 316, 17-4 PH | Excellent corrosion resistance and strength |

| Carbon & Alloy Steels | 1018, 4140, 4340 | High durability, suitable for load-bearing parts |

| Brass & Copper | C36000, C11000 | Good electrical conductivity and aesthetic finish |

| Titanium Alloys | Grade 2, Grade 5 (Ti-6Al-4V) | High strength-to-density ratio, biocompatible |

| Plastics | PEEK, Delrin, Nylon, PC | Low friction, chemical resistance, non-conductive |

Shenzhen Honyo Prototype emphasizes process optimization and metrology-backed validation to ensure each turned component meets exact design specifications. Our engineering team collaborates closely with clients during DFM analysis to recommend design adjustments that enhance manufacturability and reduce costs without compromising performance. Whether producing intricate shafts, valve bodies, or sensor housings, our precision turning services deliver consistent, high-quality results aligned with the most demanding technical requirements.

From CAD to Part: The Process

Precision Turning Production Workflow: From CAD to Finished Component

At Shenzhen Honyo Prototype, our precision turning process for CNC-machined prototypes and low-volume production parts follows a rigorously defined workflow to ensure dimensional accuracy, material integrity, and on-time delivery. This systematic approach transforms digital designs into high-fidelity physical components, minimizing risk and maximizing efficiency from initial inquiry through final inspection. The core sequence integrates advanced digital tools with expert engineering oversight: AI-Powered Quotation, Comprehensive Design for Manufacturability (DFM) Analysis, and Controlled Production Execution.

The workflow initiates with the AI-Powered Quotation System. Upon receipt of a client’s CAD model (STEP, IGES, or native formats preferred), our proprietary AI engine rapidly analyzes geometric complexity, material selection, tolerance requirements, and feature density. This system cross-references historical production data, current machine utilization, and material costs to generate an initial cost estimate and lead time projection within minutes. While this provides crucial speed for early-stage budgeting, it serves as a preliminary assessment only; the AI output explicitly flags designs requiring deeper engineering review, particularly those involving tight tolerances (<±0.005mm), thin walls, or complex secondary operations.

This triggers the Mandatory DFM Engineering Review, the cornerstone of Honyo’s precision turning success. Our senior manufacturing engineers conduct a thorough manual analysis, moving beyond the AI’s scope. We scrutinize tool access, optimal stock allowance, feasible chucking strategies, and potential vibration points. Critical attention is given to tolerance stack-up, surface finish achievability, and material-specific considerations like chip control for stainless steel or thermal management for aluminum alloys. This phase identifies potential manufacturability issues—such as unnecessarily tight tolerances on non-critical features or undercuts requiring specialized tooling—and provides actionable recommendations. Client collaboration during DFM is non-negotiable; resolving these points upfront prevents costly revisions, delays, and scrapped parts during machining. Approval of the finalized DFM report is required before production release.

Production Execution commences only after DFM sign-off. Programmers generate optimized CNC code (typically using Mastercam or Fusion 360) incorporating the agreed-upon machining strategy. Setup technicians meticulously prepare the CNC lathe (typically Fanuc or Siemens-controlled Swiss-type or fixed-bed machines), verifying tool geometry offsets, fixture alignment, and workpiece datum points against the approved setup sheet. During machining, our process employs rigorous in-process checks:

First-article inspection verifies critical dimensions per the drawing using calibrated CMMs or optical comparators.

Statistical process control (SPC) monitors key parameters like diameter consistency and surface roughness on subsequent parts.

Final inspection against all drawing specifications, including material certification review, is mandatory before shipment.

The following table summarizes critical machining parameters achievable through this disciplined workflow:

| Parameter | Typical Range (Precision Turning) | Critical Factor Influencing Range |

| :—————– | :——————————- | :————————————- |

| Dimensional Tolerance | ±0.005 mm to ±0.025 mm | Material stability, machine thermal compensation |

| Surface Roughness (Ra) | 0.4 µm to 1.6 µm | Tool geometry, feed rate, coolant application |

| Maximum Length/Diameter Ratio | 15:1 (Standard) to 25:1 (Swiss) | Machine rigidity, support bushing use |

This integrated AI Quote → DFM → Production workflow ensures Shenzhen Honyo Prototype consistently delivers precision-turned components meeting the most demanding specifications. By prioritizing engineering validation before metal removal, we transform complex CAD models into reliable, high-quality parts, enabling our clients’ rapid product development cycles with confidence in manufacturability and quality. The seamless transition from digital design to physical reality is fundamental to our value proposition in precision CNC machining.

Start Your Project

Start Your Precision Turning Project with Honyo Prototype

At Shenzhen Honyo Prototype, we specialize in high-accuracy CNC precision turning for industries that demand reliability, repeatability, and tight tolerances. Whether you’re developing medical components, aerospace fittings, automotive sensors, or industrial prototypes, our precision turning services ensure your parts meet exact specifications with consistent quality. Our advanced CNC lathes, skilled machinists, and rigorous quality control systems enable us to deliver turned components with tolerances as tight as ±0.002 mm, surface finishes down to Ra 0.4 µm, and fast turnaround times without compromising precision.

We understand that every project begins with a concept—often evolving through multiple iterations before reaching production. That’s why we offer a seamless workflow from initial design consultation to final inspection and delivery. Our engineering team works closely with clients to review part geometry, material selection, and manufacturability, helping to optimize designs for cost-efficiency and performance. From single prototypes to low-volume production runs, we support flexible batch sizes tailored to your development needs.

Our precision turning capabilities include both standard and Swiss-type CNC lathes, allowing us to handle complex geometries, slender components, and multi-feature parts with secondary operations such as threading, grooving, drilling, and knurling. We machine a wide range of materials including aluminum, stainless steel, brass, titanium, and engineering plastics, ensuring compatibility with functional and environmental requirements.

To help you determine the best approach for your project, we’ve outlined our core precision turning specifications:

| Specification | Capability |

|————–|————|

| Maximum Turning Diameter | 38 mm |

| Maximum Bar Feed Diameter | 32 mm |

| Minimum Achievable Tolerance | ±0.002 mm |

| Typical Surface Finish | Ra 0.4 – 1.6 µm |

| Standard Machines Used | CNC Swiss Lathes, Multi-axis CNC Lathes |

| Supported Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Brass (C3604), Titanium, PEEK, Delrin |

| Secondary Operations | Milling, Drilling, Tapping, Thread Cutting, Grooving, Knurling |

| Lead Time (Prototype) | 5–7 working days |

| Quality Assurance | First Article Inspection (FAI), In-process checks, Final CMM reporting |

Starting your project is simple. Share your 2D drawings, 3D models (in STEP, IGES, or SolidWorks format), and any special requirements with our team. We provide rapid feedback, including Design for Manufacturability (DFM) suggestions and a detailed quotation within 24 hours.

Partner with Honyo Prototype to bring your precision components to life with unmatched accuracy and responsiveness. For immediate assistance, contact Susan Leo at info@hy-proto.com. Let’s turn your design into a high-performance reality.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.