Contents

Manufacturing Insight: Torlon Plastic

Manufacturing Insight: Torlon Plastic for Precision CNC Machining

Torlon polyamide-imide (PAI) represents the pinnacle of high-performance thermoplastics, delivering exceptional mechanical strength, continuous service temperatures exceeding 260°C (500°F), and outstanding resistance to wear, creep, and a wide range of chemicals. Its unique properties make it indispensable for mission-critical components in aerospace, semiconductor manufacturing, medical implants, and high-temperature fluid handling systems where failure is not an option. However, unlocking Torlon’s full potential through CNC machining demands specialized expertise far beyond standard plastic fabrication due to its inherent material complexities. At Shenzhen Honyo Prototype, we possess the deep technical knowledge and controlled processes necessary to consistently produce dimensionally accurate, high-integrity Torlon parts that meet the most stringent performance requirements.

Machining Torlon successfully requires meticulous management of three interrelated challenges: moisture content, thermal behavior, and chip formation. Torlon is highly hygroscopic; inadequate pre-drying leads to steam-induced surface defects, internal voids, and catastrophic part failure during or after machining. Furthermore, its relatively high coefficient of thermal expansion and significant heat generation during cutting necessitate extremely precise thermal management to prevent dimensional drift and micro-cracking as the material cools. Chip control is also critical, as improper tool geometry or feed rates can cause chip welding or surface tearing, compromising the final finish and structural integrity. Key thermal properties driving these challenges are summarized below:

| Property | Value for Torlon 4203/4301 | Significance for CNC Machining |

| :————————— | :————————- | :————————————————- |

| Coefficient of Thermal Expansion (CTE) | 45-50 x 10⁻⁶ /°C | High dimensional sensitivity to temperature fluctuations; requires strict thermal control during machining and cooling |

| Glass Transition Temperature (Tg) | ~275°C | Machining near Tg risks surface melting; low cutting speeds essential to minimize heat generation |

| Maximum Moisture Content (Pre-Machining) | < 0.02% | Excess moisture causes splaying, voids, and poor surface finish; mandatory extended drying |

Honyo Prototype addresses these challenges through a rigorously controlled, end-to-end manufacturing protocol. Our process begins with proprietary multi-stage vacuum drying cycles, precisely calibrated to the specific Torlon grade and part geometry, ensuring moisture levels are reduced well below critical thresholds before any cutting occurs. We utilize specialized CNC toolpaths optimized for minimal heat generation, employing sharp, high-positive rake angle carbide tools (typically 8°-12°) and meticulously managed feed rates and depths of cut. Real-time in-process monitoring of tool temperature and vibration allows for immediate parameter adjustment, preventing thermal runaway. Crucially, our fixtures incorporate thermal isolation and controlled cooling protocols to manage part contraction uniformly, mitigating internal stresses that lead to warpage or cracking post-machining.

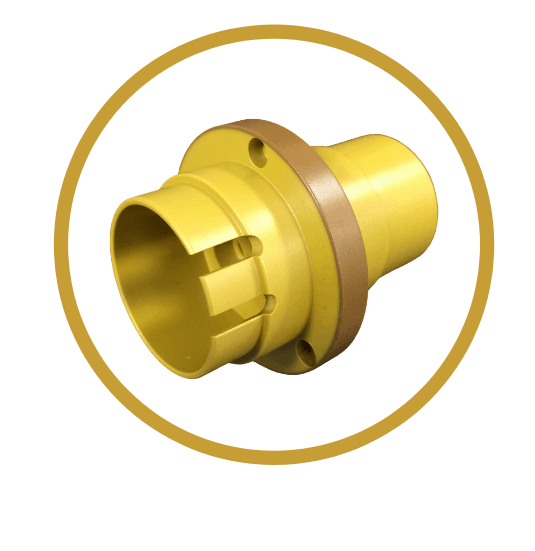

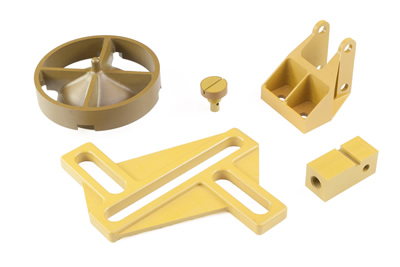

This systematic approach enables Honyo to deliver Torlon components with tolerances down to ±0.025mm and superior surface finishes (Ra < 0.8 µm) consistently, even for complex geometries. We routinely machine critical components such as semiconductor wafer handling guides, aerospace thrust washer assemblies, and high-pressure fluid system seals where Torlon’s performance is non-negotiable. Partnering with Honyo ensures your demanding Torlon applications are backed by proven material science expertise and precision manufacturing execution, transforming this challenging polymer into reliable, high-value end-use parts.

Technical Capabilities

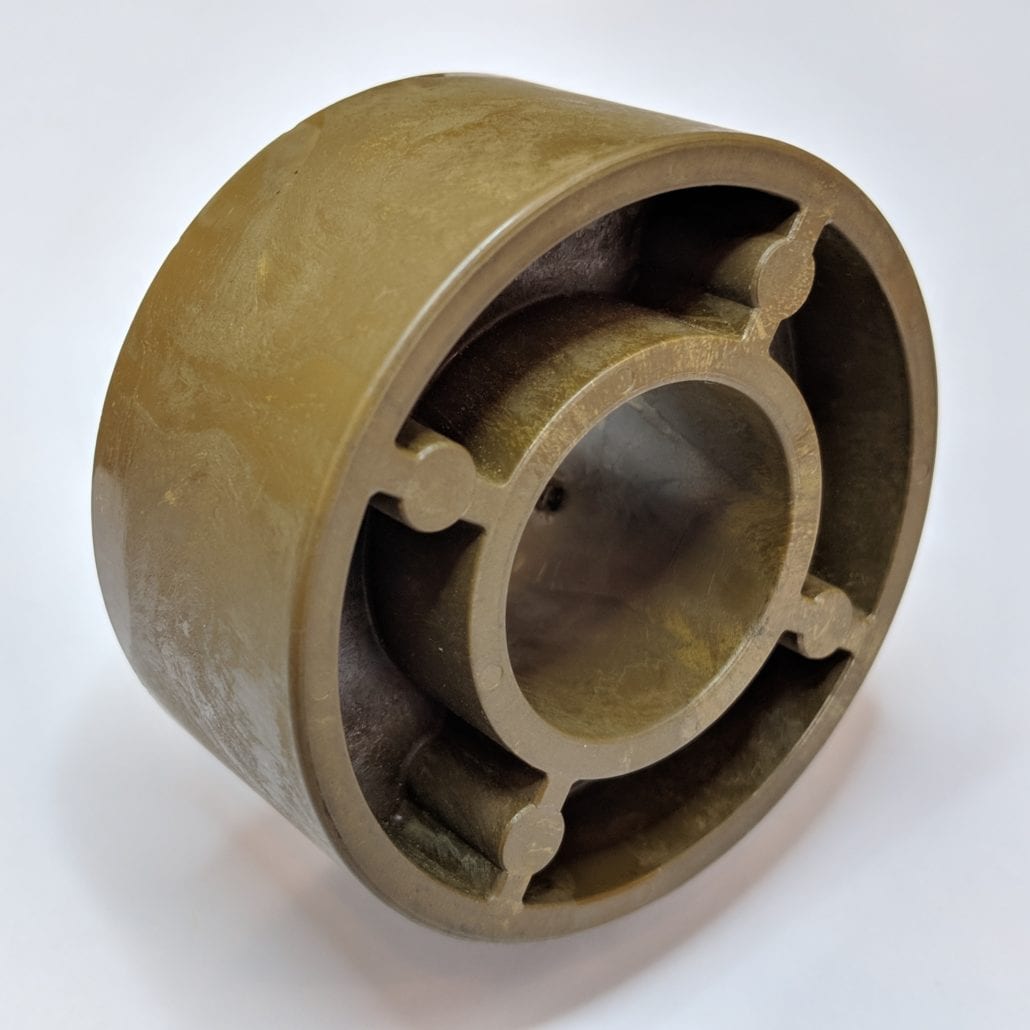

Shenzhen Honyo Prototype delivers high-precision CNC machining services for high-performance thermoplastics, with Torlon (PAI – Polyamide-Imide) being one of the most demanding and rewarding materials in our portfolio. Known for its exceptional strength, thermal stability, and resistance to wear and chemicals, Torlon is ideal for aerospace, semiconductor, medical, and oil & gas applications where reliability under extreme conditions is non-negotiable. Our expertise in 3-axis, 4-axis, and 5-axis milling, as well as precision turning, enables us to machine complex geometries while maintaining the structural integrity and dimensional accuracy critical to Torlon components.

Torlon’s high glass transition temperature (up to 275°C) and excellent creep resistance make it suitable for long-term use in high-stress environments. However, its processing presents unique challenges, including high moisture absorption and sensitivity to thermal gradients during machining. At Honyo Prototype, we mitigate these challenges through strict material conditioning protocols, including pre-drying at controlled temperatures (typically 150°C for 4–6 hours) before machining. Our CNC workflows are optimized for low residual stress, using sharp, polished carbide tooling and carefully managed cutting parameters to minimize heat generation and prevent surface cracking or delamination.

Our 5-axis CNC milling capabilities allow for the production of complex, multi-faceted components from Torlon in a single setup, reducing cumulative tolerances and improving feature alignment. 4-axis indexing supports high-accuracy rotational features, while 3-axis milling remains ideal for prismatic or planar geometries. For cylindrical or rotational parts, our precision turning centers deliver fine surface finishes and consistent diametrical control, even in long, slender configurations.

We specialize in tight-tolerance machining, consistently holding tolerances down to ±0.005 mm for critical features. Our in-process inspection protocols, including CMM and laser probing, ensure compliance with stringent quality requirements. Below is a summary of our technical capabilities and achievable tolerances for Torlon plastic under controlled machining conditions.

| Feature | Typical Tolerance | Notes |

|——–|——————-|——-|

| Linear Dimensions | ±0.010 mm | Standard precision; down to ±0.005 mm on critical features |

| Hole Diameter | +0.015 / -0.000 mm | Reamed or precision drilled; honing available |

| Positional Tolerance | ±0.015 mm | GD&T compliant; true position control |

| Flatness | 0.025 mm per 100 mm | Stress-relieved stock recommended |

| Surface Finish (Ra) | 0.8 – 3.2 µm | As-machined; polishing available to 0.4 µm Ra |

| Angular Tolerance | ±0.1° | 4-axis and 5-axis capabilities ensure high angular accuracy |

| Thread Accuracy | Class 6G (metric), Class 2B (imperial) | Tapped or single-pointed |

Material options include Torlon 4203, 4301, 5030, and 7130, each selected based on thermal, mechanical, or wear requirements. All stock is conditioned prior to machining, and parts are stress-relieved post-process when necessary. With full traceability, ISO-compliant documentation, and rapid prototyping to low-volume production, Shenzhen Honyo Prototype ensures Torlon components meet the highest standards of performance and reliability.

From CAD to Part: The Process

Torlon CNC Machining Workflow: From CAD to Precision Component

At Shenzhen Honyo Prototype, machining Torlon (polyamide-imide) demands a specialized, controlled workflow due to its exceptional strength, thermal stability, and inherent sensitivity to thermal stress and moisture absorption. Our process rigorously transitions from digital design to certified physical part, mitigating risks inherent in this high-performance polymer.

The workflow initiates with AI-Powered Quoting. Upon receiving the client’s CAD model (STEP/IGES preferred), our proprietary AI engine performs rapid material utilization and process simulation. Crucially, it factors Torlon-specific parameters: its high cost per kilogram, significant thermal expansion coefficient, stringent moisture requirements, and slower optimal machining speeds compared to standard plastics like POM or ABS. This generates an accurate cost and lead time estimate within hours, highlighting potential manufacturability flags early, such as features prone to deflection or thermal distortion.

This transitions directly into the mandatory Design for Manufacturability (DFM) Review. Our senior engineers conduct a deep dive, focusing exclusively on Torlon’s constraints. We scrutinize wall thickness uniformity (minimum 1.5mm recommended to prevent warpage), eliminate sharp internal corners (mandating ≥ R0.5mm radii), verify feasible tolerances considering post-machining relaxation, and assess part geometry for secure, non-marring fixturing. Critical feedback is provided to the client before programming begins, ensuring the design aligns with Torlon’s physical behavior during and after machining. Attempting to hold tight tolerances (e.g., < ±0.05mm) on large, thin-walled Torlon sections without DFM input is a primary cause of field failure.

Following DFM sign-off, Precision CNC Production commences under strictly controlled conditions. Torlon stock undergoes mandatory 48-hour oven drying at 150°C immediately prior to machining to eliminate absorbed moisture, preventing steam-induced surface defects. Machining occurs in a climate-controlled environment (22±1°C, 45% RH). We employ sharp, polished carbide tooling with high positive rake angles, utilizing slow feed rates (40-60% of PEEK speeds) and light, consistent depths of cut to minimize heat generation. Coolant is generally avoided; instead, optimized air blast ensures chip evacuation without thermal shock. All critical dimensions undergo in-process inspection using calibrated CMMs to account for any thermal drift. Post-machining, parts undergo stress-relief annealing per material spec before final dimensional certification.

Material stability is paramount. Key Torlon properties directly influencing this workflow include:

| Property | Value for Torlon 4203L | Impact on Machining Process |

| :———————- | :——————— | :———————————————- |

| Density (g/cm³) | 1.42 | Affects chip load and spindle power requirements |

| CTE (mm/mm/°C x 10⁻⁶) | 40 | Mandates strict thermal control & tolerance planning |

| Max Continuous Use (°C) | 250 | Dictates max allowable process temperatures |

| Moisture Absorption (%) | 1.0 (24h, 50% RH) | Requires mandatory pre-machining drying cycle |

| Typical Machining Tolerance | ±0.05 – 0.10 mm | Tighter tolerances require significant DFM input |

This integrated workflow – AI quoting informed by material science, rigorous Torlon-specific DFM, and environmentally controlled precision machining – ensures Honyo Prototype delivers dimensionally stable, high-integrity Torlon components that perform reliably in demanding aerospace, semiconductor, and medical applications. We prioritize material understanding over speed, guaranteeing part functionality.

Start Your Project

Start Your Torlon Plastic CNC Machining Project with Honyo Prototype

When engineering demands high-performance thermoplastics that can withstand extreme environments, Torlon plastic stands out as one of the most reliable materials available. At Shenzhen Honyo Prototype, we specialize in precision CNC machining of Torlon (PAI) components for industries ranging from aerospace and defense to semiconductor and medical device manufacturing. Known for its exceptional strength, thermal stability, and resistance to wear and chemicals, Torlon is ideal for applications where failure is not an option. However, its high-performance characteristics also present unique machining challenges that require expert handling, precise tooling, and deep material understanding—capabilities we’ve refined over years of specialized production.

Our CNC machining services are tailored to meet the exacting standards required by advanced engineering projects. Whether you’re developing high-load bearing components, seals, insulators, or precision bushings, our team ensures dimensional accuracy, surface integrity, and consistent repeatability. We work with various grades of Torlon, including Torlon 4203, 4301, and 5030, each offering distinct advantages depending on operating temperature, wear resistance, and mechanical load requirements.

To ensure optimal results, we implement controlled machining parameters such as reduced cutting speeds, specialized tool geometries, and strict thermal management protocols to prevent material degradation during processing. Post-machining, components undergo precision inspection using coordinate measuring machines (CMM) and other metrology tools to verify compliance with tight tolerances—down to ±0.005 mm when required.

Below is a summary of key physical and mechanical properties for commonly machined Torlon grades:

| Property | Torlon 4203 | Torlon 4301 | Torlon 5030 |

|——————————-|———————|———————|———————|

| Tensile Strength (MPa) | 110 | 130 | 124 |

| Flexural Strength (MPa) | 186 | 207 | 193 |

| Heat Deflection Temp (°C) | 275 | 279 | 288 |

| Continuous Use Temp (°C) | 250 | 260 | 275 |

| Coefficient of Friction | Low | Low | Very Low |

| Machinability Rating | Moderate | Moderate | Moderate to Challenging |

All materials are sourced from certified suppliers and processed in a climate-controlled environment to maintain consistency and part integrity. We also offer secondary services such as annealing, stress relieving, and custom finishing to meet your application-specific needs.

Starting your project with Honyo Prototype is simple. If you’re working with demanding specifications and require high-precision Torlon components, contact Susan Leo directly at info@hy-proto.com. With over a decade of experience in advanced polymer machining, Susan will guide you through material selection, design optimization, and production planning to ensure your prototype or production run meets the highest standards of performance and reliability.

Don’t let the complexities of machining high-performance plastics slow down your innovation. Reach out today and let Honyo Prototype turn your design into a high-precision reality.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.