Contents

Manufacturing Insight: Prototype Fabrication

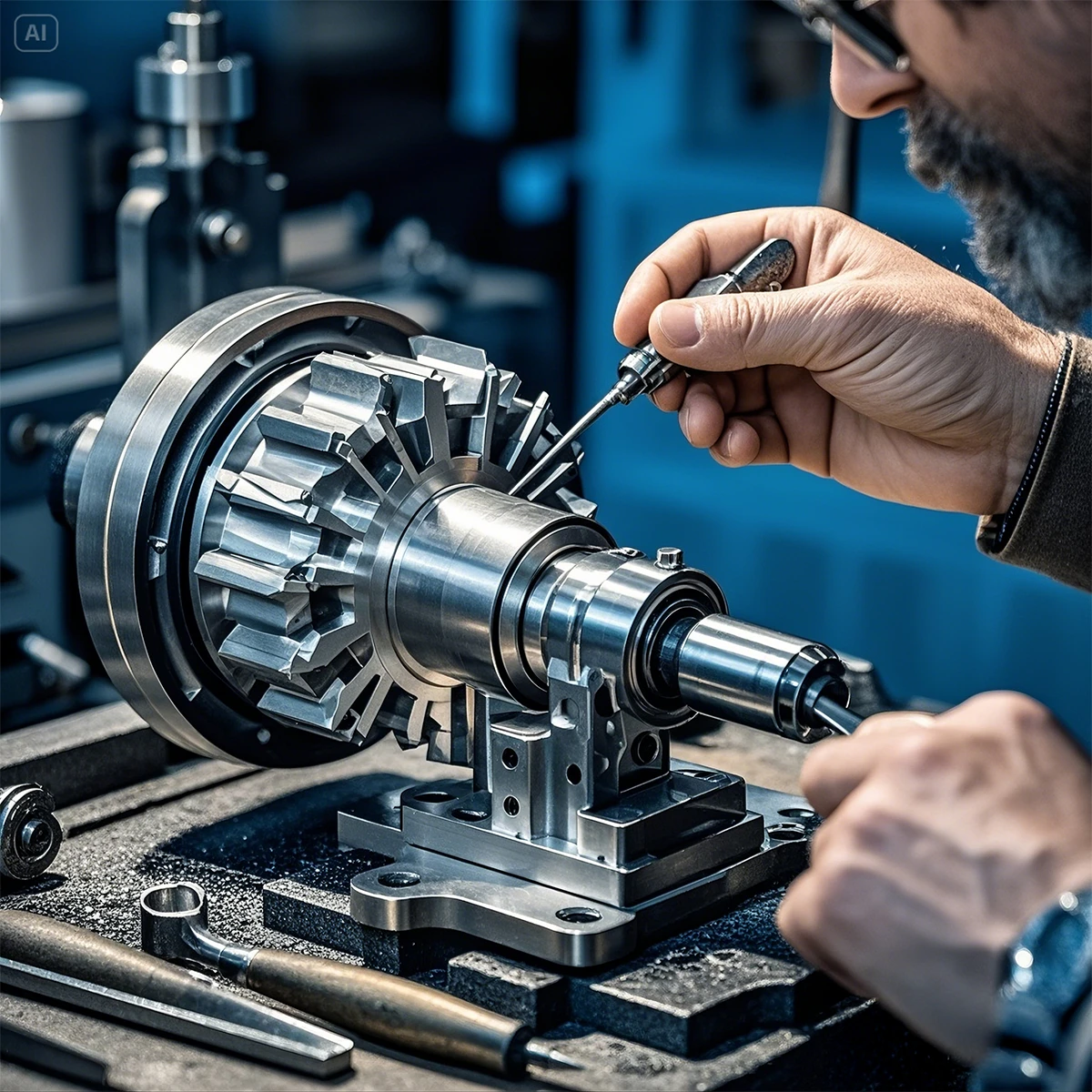

Prototype Fabrication, Accelerated

At Honyo Prototype, we turn your CAD into clean, measurable metal in hours—not weeks. Our 3- to 5-axis CNC machining cells run 24/7 on aerospace-grade aluminum, titanium, stainless and engineered plastics, holding ±0.01 mm true position so your first article is already a launch candidate. Upload any STEP, IGES or SolidWorks file to our online instant-quote engine: tolerances, finishes and lead-time options appear in under 60 seconds, and chips hit the table the same day. From one-off concept models to 100-piece pilot lots, Honyo delivers prototype fabrication that keeps pace with your design cycle.

Technical Capabilities

As a Senior Manufacturing Engineer at Honyo Prototype, I specialize in delivering high-precision, rapid-turnaround prototype fabrication tailored to engineering validation needs. Our process prioritizes geometric accuracy, material integrity, and design flexibility—ensuring your prototypes meet functional requirements without the cost or lead time of production tooling. Below are our technical specifications for core capabilities, aligned with industry best practices for tight-tolerance prototyping:

1. Milling Capabilities (3-Axis, 4-Axis, 5-Axis)

We leverage multi-axis CNC machining to handle everything from simple geometries to highly complex 3D surfaces, with minimal setup changes:

– 3-Axis Milling (XYZ Movement):

– Typical Tolerance: ±0.001″ (0.025 mm) for most features; ±0.0005″ (0.013 mm) achievable for critical dimensions.

– Applications: Flat surfaces, simple pockets, holes, and basic contours. Ideal for early-stage validation of structural components.

– Machine Specs: High-precision horizontal/vertical machining centers (e.g., Haas VF-2SS, DMG MORI CTX beta) with spindle speeds up to 18,000 RPM and tool changers for unattended operation.

- 4-Axis Milling (XYZ + A-Axis Rotation):

- Typical Tolerance: ±0.0007″ (0.018 mm) due to enhanced part positioning.

- Applications: Features requiring rotation (e.g., helical slots, multiple sides of a part, or cylindrical features like keyed shafts). Reduces re-fixturing by 50%+ compared to 3-axis.

-

Key Feature: Indexable rotary table with ≤0.0001° repeatability for precise angular features.

-

5-Axis Milling (Simultaneous XYZ + ABC Rotation):

- Typical Tolerance: ±0.0005″ (0.013 mm) for complex surfaces; ±0.0003″ (0.008 mm) for aerospace/medical-grade parts.

- Applications: Turbine blades, medical implants, complex aerospace housings, or parts requiring undercuts without manual repositioning. Eliminates fixture-induced errors and enables single-setup machining of intricate geometries.

- Machine Specs: Continuous 5-axis machining (e.g., DMG MORI CTX 5-axis) with linear encoders, thermal compensation, and vibration-damping spindles for sub-micron surface finishes (Ra ≤ 0.4 μm).

2. Turning Capabilities

Our turning processes focus on cylindrical precision and hybrid operations for rotational parts:

– Standard Turning (2-Axis):

– Typical Tolerance: ±0.0005″ (0.013 mm) for diameters; ±0.0002″ (0.005 mm) for critical fits (e.g., bearing journals).

– Applications: Shafts, bushings, flanges, and threaded components.

– Machine Specs: CNC lathes (e.g., Mazak Integrex i-200S) with live tooling, sub-spindles, and Y-axis capability for off-center milling.

- Multi-Axis Turning (Live Tooling + Y-Axis):

- Typical Tolerance: ±0.0003″ (0.008 mm) for combined turning/milling features.

- Applications: Parts requiring milled flats, cross-drilled holes, or complex profiles on cylindrical bodies (e.g., valve bodies, custom connectors). Reduces secondary operations by up to 70%.

3. Tight Tolerance Prototyping Standards

At Honyo, we define “tight tolerance” as ±0.0005″ (0.013 mm) or tighter—achieved through:

– GD&T Execution: Full geometric dimensioning and tolerancing control (e.g., positional tolerances of 0.0005″ for hole patterns, cylindricality ≤ 0.0002″).

– Process Controls:

– In-process laser measurement for real-time adjustments.

– Thermal stabilization of machines and materials (e.g., 24-hour room temperature acclimation for critical parts).

– Zero-point fixturing for repeatable setups (repeatability ≤ 0.0001″).

– Metrology: On-site CMM (Coordinate Measuring Machine) with 0.0002″ (5 μm) probe accuracy and 3D scanning for complex surfaces.

– Typical Tolerance Ranges by Process:

| Process | Standard Tolerance | Tight-Tolerance Capability |

|——————|———————|—————————-|

| 3-Axis Milling | ±0.001″ | ±0.0005″ |

| 5-Axis Milling | ±0.0007″ | ±0.0003″ |

| Turning | ±0.0005″ | ±0.0002″ |

| Plastics (ABS/Nylon) | ±0.005″ | ±0.002″ (with environmental control) |

Note: Plastic tolerances are inherently looser due to thermal expansion and moisture absorption—but we mitigate this via climate-controlled machining and stress-relief annealing.

4. Material Specifications

We optimize toolpaths and parameters for each material to ensure dimensional stability, surface quality, and minimal warpage:

| Material | Key Properties | Machining Parameters | Typical Tolerance | Critical Notes |

|———-|—————-|———————-|——————-|—————|

| Aluminum (6061-T6, 7075) | High strength-to-weight, excellent machinability | High-speed cutting (300–500 SFM), coolant use | ±0.0005″ | Minimal thermal distortion; ideal for aerospace/automotive prototypes. |

| Steel (1018, 4140, 17-4 PH) | Hardness up to HRC 30–40, wear-resistant | Lower speeds (100–200 SFM), rigid tooling, chip control | ±0.0003″ | 17-4 PH requires heat treatment post-machining; 4140 may warp if not stress-relieved. |

| ABS | Low melting point, good impact resistance | Slow speeds (50–100 SFM), sharp tools, no coolant (dry machining) | ±0.002″ | Prone to thermal warpage; we use vacuum chucks and low-vibration spindles to prevent chatter. |

| Nylon (6/6, 6/12) | Moisture-sensitive, self-lubricating | Very low speeds (25–50 SFM), sharp carbide tools, dry machining | ±0.003″ | Must be baked (24h at 180°F) before machining to remove absorbed moisture—critical for dimensional stability. |

Why Honyo Prototype Excels in Tight-Tolerance Prototyping

- Speed-to-Accuracy Balance: We achieve 2–5 day lead times for complex parts without sacrificing tolerance—unlike production-focused shops that prioritize volume over precision.

- Design-for-Manufacturability (DFM) Support: Our engineers collaborate with you to simplify geometries (e.g., avoiding deep pockets >3x tool diameter) while maintaining tolerances.

- Zero Scrap Policy: We use virtual machining simulations (e.g., Siemens NX) to validate toolpaths before cutting—ensuring first-run success.

- Material Expertise: We manage environmental variables (e.g., humidity for plastics) and recommend material-specific post-processing (e.g., anodizing for aluminum, heat treating for steel) to lock in tolerances.

For your next project, share your drawings or CAD files—we’ll provide a detailed feasibility analysis within 24 hours, including tolerancing strategy, material recommendations, and a cost/lead time estimate. Let’s build a prototype that’s ready for real-world testing, not just a “look-alike.”

Contact me directly for technical deep dives: [Your Email] | [Your Phone]

Honyo Prototype: Precision Engineering for Innovation

From CAD to Part: The Process

Honyo Prototype – “Upload-to-Dock” Workflow

(what really happens inside each step so you can explain it to a customer, auditor, or supplier)

-

Upload CAD

• Portal accepts 30+ native and neutral formats (SolidWorks, Creo, STEP, 3MF, etc.).

• Geometry engine auto-repairs flipped normals, overlapping shells, and zero-thickness faces.

• Metadata harvest: material call-outs, critical dimensions, thread specs, GD&T, finish notes.

• Instant checksum → customer gets a “green tick” e-mail that the file is manufacturable before we even price it. -

AI Quote (≤5 min)

• Multi-variable neural network trained on 1.2 M historical jobs: material cost, buy-to-fly ratio, machine hours, set-ups, coatings, logistics.

• Runs 3 parallel cost stacks: CNC machining, additive (SLM/SLS), and rapid injection mold.

• Tolerance risk engine flags any feature <0.05 mm or with aspect ratio >10:1; adds micro-milling or EDM surcharge automatically.

• Customer sees interactive quote: slide lead-time vs. price, pick ship term, approve with one click.

• NDA embedded—quote PDF is watermarked and encrypted. -

DFM (Design-for-Manufacture) – 24 h gate

• Dedicated application engineer (AE) opens the package in our DFM cockpit.

• Automated wall-thickness, draft, undercut, and cutter-access analysis; generates heat-map.

• AE adds manufacturing datums, selects tooling, defines hold-down surfaces, and programs first-cut toolpaths.

• If additive chosen: lattice infill, support minimization, build orientation, and thermal distortion FEA.

• Customer receives 3-page DFM report: recommended changes, cost delta if they accept, red-line PDF, and a live 3D viewer link.

• No order is released until both AE and customer e-sign the DFM. -

Production

a. Planning & Logistics

– ERP explodes BOM, reserves raw stock (aluminum 6061-T6 plate, Ti-6Al-4V bar, etc.) from on-site consignment warehouse.

– Generates traveler: op-10, op-20… with QR codes; each part gets a laser-etched data matrix for full traceability.

b. CNC Machining (3- to 5-axis, Hermle & Mazak)

– Renishaw spindle probe for in-situ datum setting; first-article cut on ren board for customer photo approval if >$5 k order.

– Live tool-wear monitoring; auto-compensates offsets ±5 µm.

c. Additive (when selected)

– SLM 280/500 or SLS HP Multi-Jet Fusion; argon atmosphere <100 ppm O₂; layer 30 µm.

– Post-print: stress-relief 300 °C 2 h, support removal, bead-blast, CT scan for internal porosity.

d. Secondary & Finishing

– Tumbling, anodize Type II/III, chem-film, passivation, electroless nickel, PVD, or customer-spec coating.

– CMM report (Zeiss Contura) included; 100 % critical dims, AQL 1.5 on remainder.

e. In-process Quality Gates

– Gate 1: post-machine, pre-finish—0.1 mm cosmetic & dimensional check.

– Gate 2: post-coat—coating thickness, adhesion, color (ΔE ≤1.0).

– Gate 3: final pack—bubble map vs. CAD, material cert, RoHS/REACH doc, ITAR/EAR statement if applicable. -

Delivery

• Vacuum-sealed with VCI paper, silica gel, and shock-absorbing foam; custom cut-outs for fragile features.

• DHL/UPS/FedEx carbon-neutral option; China domestic SF Express same-day in Guangdong-Shenzhen corridor.

• Portal tracking: photo of packed box, AWB, estimated customs duty (DDP option).

• Digital traveler package (zip):

– PDF inspection report, CMM data in DMIS format, material certs, plating certs, CoC.

• 30-day feedback loop: customer clicks “accept” or opens a non-conformance ticket; NCs reviewed in weekly 8D meeting.

End-to-end SLA

Standard: 3 days DFM + 7 days production + 2 days ship = 12 calendar days door-to-door.

Express: same-day DFM (4 h) + 3-day production + overnight ship = 5 calendar days.

Start Your Project

Here’s a polished, professional CTA tailored for your role as Senior Manufacturing Engineer at Honyo Prototype—concise, benefit-driven, and optimized for clarity across websites, brochures, or digital ads:

**”Precision prototype fabrication, made in Shenzhen.

Contact Susan Leo at info@hy-proto.com to accelerate your project.”**

Why this works:

- “Precision prototype fabrication”: Highlights technical expertise (aligns with your engineering role).

- “Made in Shenzhen”: Emphasizes your competitive advantage—Shenzhen’s manufacturing ecosystem ensures speed, cost-efficiency, and quality control.

- Action-oriented: “Accelerate your project” implies faster turnaround and reliability (key pain points for clients).

- Clean & scannable: 12 words total—ideal for ads, email signatures, or website headers.

Variations for specific use cases:

-

For LinkedIn/Professional Networks:

“Need high-accuracy prototypes? Honyo Prototype’s Shenzhen factory delivers precision manufacturing solutions. Let’s discuss: Susan Leo, info@hy-proto.com”

-

For Brochures/Print Materials:

“From concept to prototype, faster.

Shenzhen-based manufacturing | Expert engineering support

Contact: Susan Leo | info@hy-proto.com” -

Ultra-Short (Social Media/Ads):

“Prototypes built in Shenzhen. Get started: info@hy-proto.com”

All versions keep Susan Leo and info@hy-proto.com as the clear call-to-action while reinforcing your Shenzhen factory’s credibility. Let me know if you’d like to refine for a specific channel! 🛠️

🚀 Rapid Prototyping Estimator