Contents

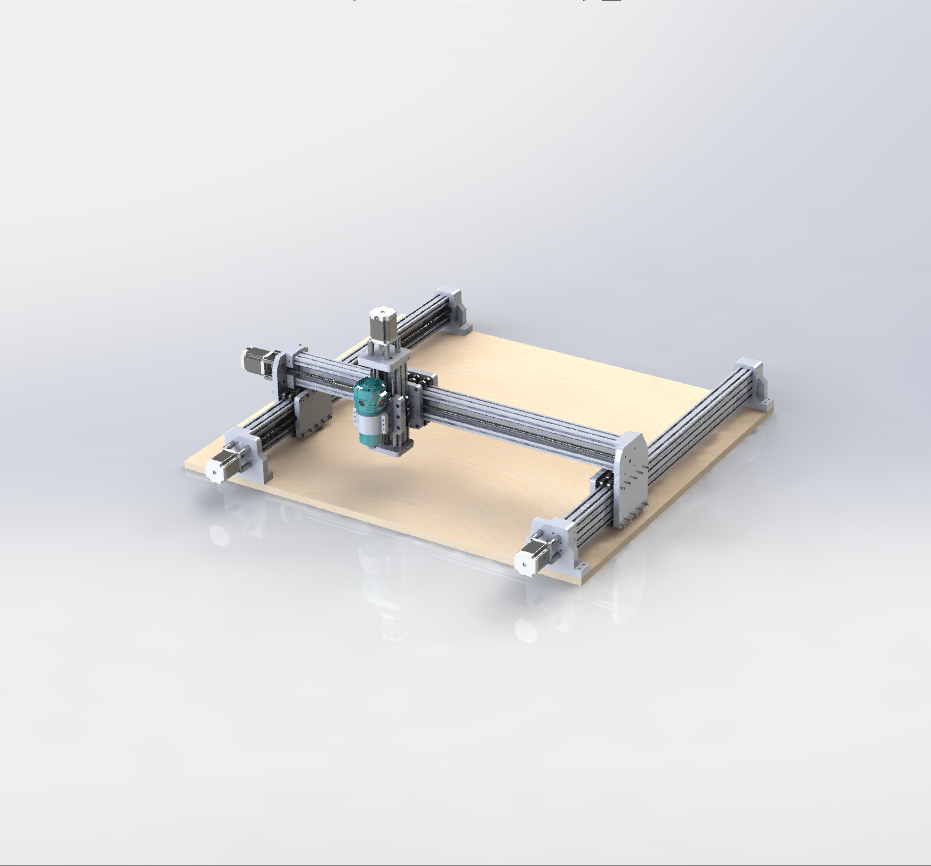

Manufacturing Insight: Stl File Cnc Router

Manufacturing Insight: STL File Utilization in CNC Routing Operations

While STL files are ubiquitous in additive manufacturing for their polygonal mesh representation, their direct application in CNC routing presents significant technical challenges. CNC routers fundamentally require precise vector-based toolpath generation from solid or surface models, whereas STL files approximate geometry through triangular facets. This inherent limitation introduces critical issues: faceted surfaces cause visible scalloping on machined parts, dimensional inaccuracies arise from mesh resolution constraints, and complex curvature cannot be faithfully reproduced. Consequently, STL files alone are unsuitable for high-precision CNC routing without specialized processing—a gap Shenzhen Honyo Prototype systematically addresses through engineered workflow solutions.

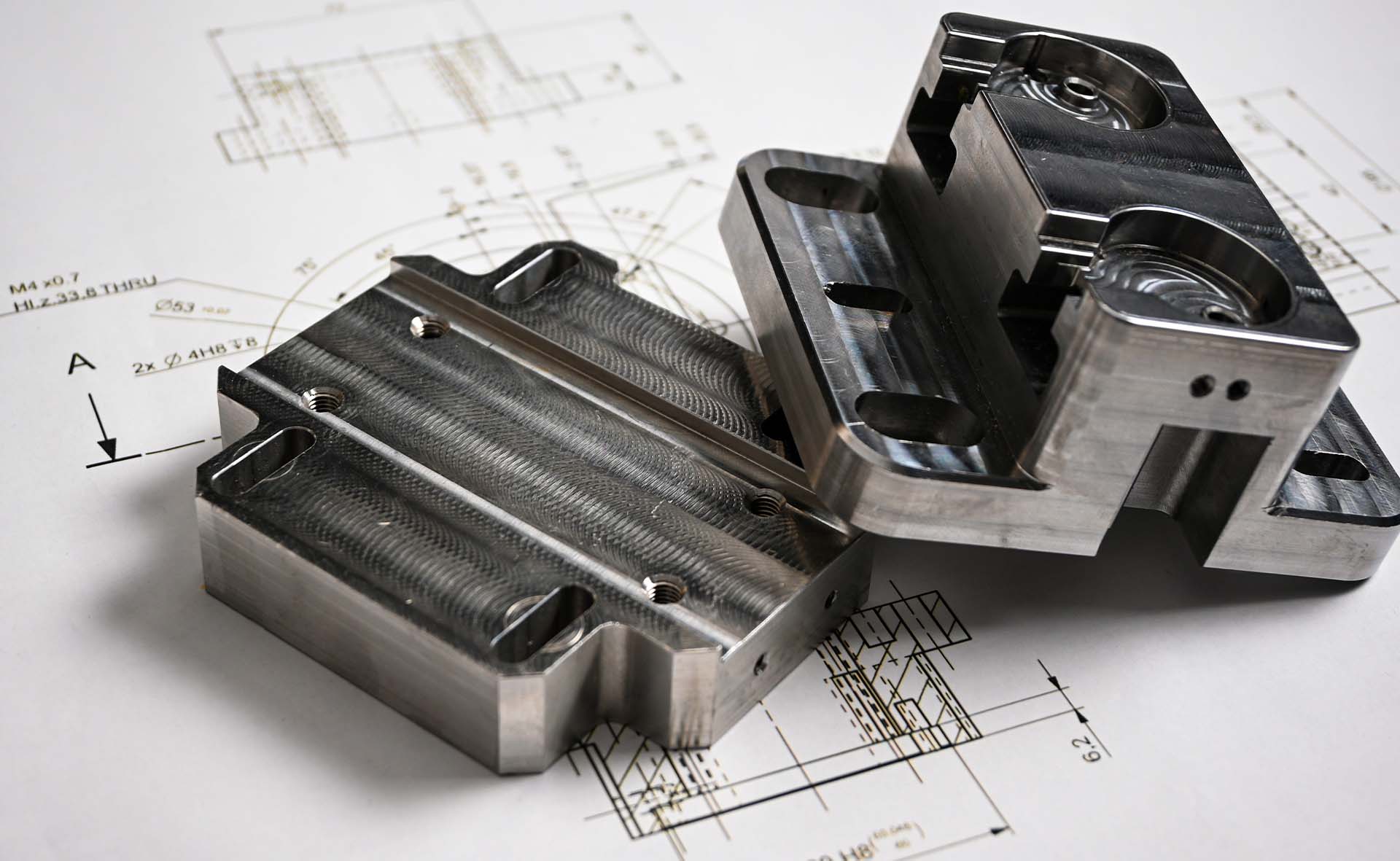

At Honyo, we deploy proprietary reverse engineering protocols to transform STL inputs into CNC-optimized formats. Our process begins with mesh refinement using Geomagic Control X, where we repair gaps, reduce noise, and optimize triangle density to minimize geometric deviation. The refined mesh is then converted into NURBS surfaces or precise CAD models via surface reconstruction algorithms, ensuring mathematically continuous geometry. This reconstructed model undergoes rigorous dimensional validation against original design intent (where available) or client specifications before final export as STEP, IGES, or DXF formats—native to industry-standard CAM systems like Mastercam and Fusion 360. This methodology guarantees smooth toolpaths, eliminates faceting artifacts, and maintains tolerances down to ±0.025 mm, critical for aerospace, automotive, and medical prototypes.

Honyo’s capability extends beyond conversion to holistic manufacturability optimization. Our engineers analyze part topology to recommend strategic stock allowances, adaptive clearing strategies, and fixture solutions that mitigate vibration in thin-walled structures. For complex organic shapes common in STL-sourced designs, we implement 5-axis simultaneous routing to maintain consistent tool engagement angles, reducing cycle times by up to 35% versus 3-axis alternatives. All processes are executed within our Shenzhen facility’s ISO 9001-certified environment, leveraging DMG MORI and ShopBot industrial routers with 0.001 mm positioning accuracy.

The comparative suitability of file formats for CNC routing is summarized below:

| File Format | Geometry Representation | Precision Level | CNC Toolpath Suitability |

|————-|————————-|—————–|————————–|

| STL | Triangular Mesh | Low (Faceted) | Poor (Requires Conversion) |

| STEP | Boundary Representation | High (NURBS) | Excellent |

| DXF | Vector Curves | Medium-High | Excellent |

| IGES | Surface Patches | High | Excellent |

By converting STL files into production-ready CAD data, Honyo eliminates the “digital disconnect” between conceptual design and subtractive manufacturing. Our clients—ranging from robotics startups to Tier-1 automotive suppliers—leverage this capability to accelerate time-to-prototype without compromising dimensional integrity. This technical bridge between mesh-based design and precision CNC routing underscores Honyo’s role as a strategic partner in the China manufacturing ecosystem, where material efficiency and first-article accuracy directly impact product validation cycles. For STL-based projects, our integrated engineering-to-machining workflow ensures that geometric complexity never compromises manufacturability.

Technical Capabilities

CNC Machining Technical Capabilities – STL File Processing

At Shenzhen Honyo Prototype, our CNC machining services are optimized for direct manufacturing from STL files, enabling rapid transition from 3D digital models to high-precision physical components. Our advanced 3-, 4-, and 5-axis CNC routers and mills are integrated with industry-leading CAM software to interpret STL data with exceptional accuracy, ensuring geometric fidelity and surface integrity across complex organic and engineered forms. This capability is particularly advantageous for prototypes, custom enclosures, molds, and ergonomic designs where freeform geometry is prevalent.

Our 3-axis CNC routers deliver robust performance for planar and prismatic parts, supporting high-speed material removal with tight positional control. When additional angular access is required, our 4-axis systems introduce rotational capability (A-axis), enabling features such as undercuts and multi-face machining with minimal fixturing. For the most geometrically complex components—such as turbine blades, aerospace brackets, or sculptural elements—our 5-axis simultaneous milling platforms provide full contouring precision, reducing setup cycles and enhancing dimensional consistency.

In addition to multi-axis milling, we offer CNC turning for cylindrical and symmetric parts, with live tooling options for mill-turn hybrid operations. This complements our STL file processing pipeline, especially for hybrid components that combine rotational bodies with sculpted features.

Tight tolerance machining is a core competency. Our systems maintain repeatability within ±0.005 mm for critical dimensions, with standard tolerances held to ±0.025 mm across most applications. Thermal compensation, in-process probing, and rigid machine calibration protocols ensure long-term precision across production runs.

We support a broad range of materials suitable for CNC routing, including engineering plastics, metals, composites, and wood-based substrates. Material selection is optimized based on functional requirements such as strength, thermal stability, and surface finish.

The following table outlines our standard machining tolerances and compatible materials:

| Feature | Specification |

|——–|—————|

| Positional Tolerance | ±0.025 mm |

| Dimensional Tolerance (Standard) | ±0.025 mm |

| Tight Tolerance Capability | ±0.005 mm |

| Surface Roughness (Typical) | Ra 3.2 µm (as-machined), down to Ra 0.8 µm (polished/finish pass) |

| Minimum Feature Size | 0.5 mm (depth/width, dependent on tooling and material) |

| Max Work Envelope (5-axis) | 1200 × 600 × 500 mm |

| Max Work Envelope (3-axis router) | 2500 × 1300 × 200 mm |

| Material Category | Examples | Notes |

|——————|———|——-|

| Plastics | ABS, PC, PMMA, POM, PEEK, Nylon | Low deformation, excellent for prototypes and end-use parts |

| Metals | Aluminum 6061, 7075, Stainless Steel 303, 316, Brass, Copper | Suitable for high-strength and thermally stable applications |

| Composites | Carbon Fiber-Reinforced Polymers, G10, FR4 | High strength-to-weight; requires specialized tooling |

| Wood & MDF | Hardwood, Plywood, MDF | Ideal for display models, molds, and architectural prototypes |

| Foams | Polyurethane, EPS | Used for master patterns and lightweight mockups |

All STL files undergo automated and manual validation to detect mesh errors, non-manifold geometry, or scaling inconsistencies prior to toolpath generation. This ensures robust manufacturability and minimizes processing delays.

Shenzhen Honyo Prototype combines advanced hardware, stringent quality control, and deep process expertise to deliver precision CNC-machined parts directly from STL data, meeting the demanding requirements of industries ranging from medical and automotive to consumer electronics and industrial design.

From CAD to Part: The Process

From CAD to Precision Part: STL File CNC Routing Workflow at Honyo Prototype

At Shenzhen Honyo Prototype, transforming your STL file into a high-quality CNC routed prototype follows a rigorous, optimized workflow designed for speed, accuracy, and manufacturability. This integrated process minimizes delays and ensures your part meets specifications from the initial inquiry through to final production. The journey begins when you submit your STL file through our online portal. Our proprietary AI-driven quoting system instantly analyzes the geometry, material requirements, and dimensional complexity. This system evaluates factors such as part volume, surface area, feature density, and inherent manufacturability constraints specific to CNC routing. Within minutes, you receive a detailed quote covering material costs, machine time, finishing options, and a precise lead time estimate, eliminating lengthy manual review bottlenecks. Crucially, the AI performs an initial automated validation check, flagging potential showstoppers like non-manifold geometry or extreme aspect ratios before human engineering review.

Following quote acceptance, the file enters our core Design for Manufacturability (DFM) phase, led by our experienced CNC engineering team. This is not a simple file check; it is a proactive optimization step critical for successful routing. Engineers meticulously review the STL against CNC router capabilities, focusing on router-specific challenges such as minimum wall thickness, undercuts, internal corner radii, and overall structural integrity during machining. We identify features requiring specialized tooling or multi-axis setups and assess the optimal material stock size and fixture strategy. Potential issues like thin sections prone to vibration or features requiring excessive tool changes are addressed collaboratively with the client, often suggesting subtle, non-functional geometry tweaks that significantly enhance machinability, reduce cycle time, and lower cost without compromising the part’s intended function. This phase ensures the design is not just possible, but optimal for efficient CNC routing production.

Once DFM is approved, the part moves directly into production. Our CAM specialists generate highly efficient, collision-free toolpaths using industry-leading software, leveraging the insights from the DFM review. Material procurement is synchronized with the production schedule. Machining occurs on our modern CNC router fleet, featuring high-precision spindles and robust workholding. The process involves roughing to remove bulk material, followed by precise semi-finishing and finishing passes to achieve the required surface quality and dimensional tolerances. Throughout machining, in-process inspections verify critical features. Post-machining, parts undergo deburring, optional finishing (sanding, priming), and final dimensional inspection against the original CAD model or provided drawing. The result is a precision prototype, manufactured efficiently and reliably, ready for your application.

Key CNC Router Production Specifications at Honyo Prototype

| Parameter | Capability | Typical Tolerance |

| :—————– | :————————————– | :—————- |

| Max Work Envelope | 1300 x 2500 x 200 mm (X, Y, Z) | N/A |

| Spindle Speed | Up to 24,000 RPM | N/A |

| Primary Materials | ABS, PMMA, PVC, Wood, Composites, Soft Metals (Al, Brass) | ±0.05 mm |

| Positioning Accuracy | ±0.02 mm | N/A |

| Surface Finish (As Machined) | Ra 3.2 µm (typical) | N/A |

Start Your Project

Start Your CNC Router Project with Precision and Confidence

When it comes to turning your STL file into a high-quality physical prototype or production part, precision, speed, and material expertise are non-negotiable. At Shenzhen Honyo Prototype, we specialize in CNC router machining services tailored for complex 3D models derived from STL data. Whether you’re developing architectural models, custom signage, mold patterns, or functional prototypes, our advanced CNC routing capabilities ensure dimensional accuracy, superior surface finish, and fast turnaround times.

Our process begins the moment we receive your STL file. Using industry-leading CAM software, our engineering team converts your 3D model into optimized toolpaths that maximize material efficiency and machining accuracy. We support a wide range of engineering-grade plastics, woods, foams, composites, and soft metals—ensuring that your part not only meets design intent but performs under real-world conditions.

We understand that every project has unique requirements. That’s why we conduct a comprehensive design for manufacturability (DFM) review before any cutting begins. This proactive step identifies potential issues related to wall thickness, undercuts, tool access, and structural integrity—helping you avoid costly revisions and delays.

At Honyo Prototype, we combine state-of-the-art 3-, 4-, and 5-axis CNC routers with rigorous quality control protocols. Our machines operate with tolerances as tight as ±0.05 mm, and every part is inspected using precision measuring instruments to ensure compliance with your specifications.

Below is an overview of our standard CNC router capabilities:

| Specification | Detail |

|—————|——–|

| Machine Types | 3-axis, 4-axis, and 5-axis CNC routers |

| Work Envelope | Up to 2500 mm × 1300 mm × 200 mm (custom setups available) |

| Positioning Accuracy | ±0.02 mm |

| Repeatability | ±0.01 mm |

| Typical Tolerance | ±0.05 mm |

| Supported Materials | ABS, PVC, acrylic, wood (MDF, plywood), foam (EPS, PU), HDPE, polycarbonate, aluminum (soft alloys), and composites |

| Surface Finish | As-machined, sanded (grades 180–600), primed, or painted |

| Lead Time | 3–7 business days (varies by complexity and quantity) |

| File Formats Accepted | STL, STEP, IGES, DWG, DXF |

Your STL file is more than just a digital model—it’s the blueprint of your innovation. Let us help you bring it to life with unmatched craftsmanship and technical expertise. We handle projects of all scales, from one-off prototypes to low-volume production runs, with consistent quality and on-time delivery.

Don’t leave your project to chance. Partner with a team that understands the nuances of CNC routing and STL-based manufacturing.

Contact Susan Leo today at info@hy-proto.com to start your project. Include your STL file and any specific requirements, and we’ll provide a detailed quote within 4 business hours. At Shenzhen Honyo Prototype, we’re not just service providers—we’re your manufacturing partners, committed to turning your vision into reality.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.