Contents

Manufacturing Insight: Uv Stable Plastic Sheet

Manufacturing Insight: UV Stable Plastic Sheet Fabrication

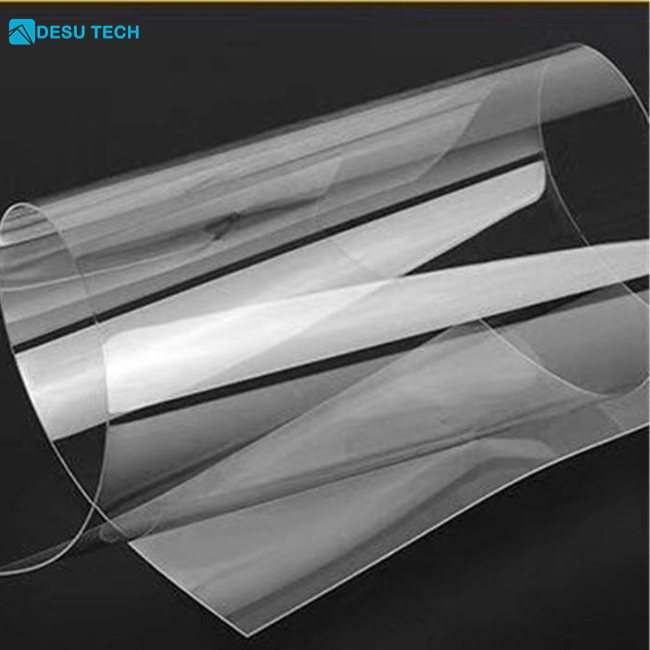

UV stable plastic sheets represent a critical material solution for outdoor applications where prolonged sunlight exposure degrades standard polymers. At Shenzhen Honyo Prototype, we specialize in the precision fabrication of these engineered sheets, ensuring long-term performance, color fidelity, and structural integrity under solar radiation. Understanding the material science and controlled processing is paramount for reliable end-use components in demanding environments like architectural glazing, solar panel housings, transportation signage, and outdoor equipment enclosures.

Material stability hinges on proprietary additive packages integrated during compounding. Primary mechanisms include Hindered Amine Light Stabilizers (HALS) which scavenge free radicals generated by UV photons, and Ultraviolet Absorbers (UVAs) that convert harmful radiation into negligible heat. The effectiveness depends on homogeneous dispersion of these additives within the polymer matrix—typically polycarbonate (PC), acrylic (PMMA), or polyethylene terephthalate glycol (PETG)—and precise control over processing temperatures to prevent additive degradation during extrusion. Standard plastics without these stabilizers experience rapid chain scission, leading to yellowing, surface cracking, loss of impact strength, and reduced transparency within months of outdoor exposure.

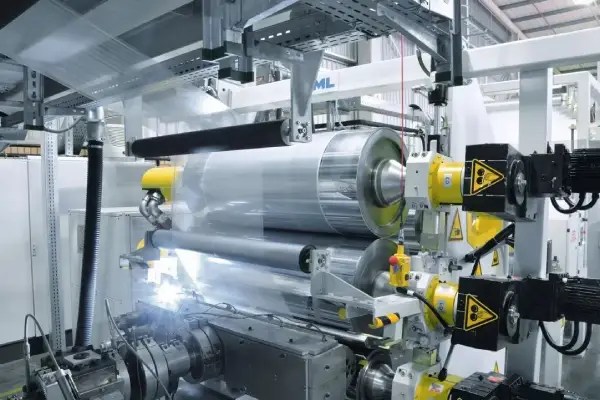

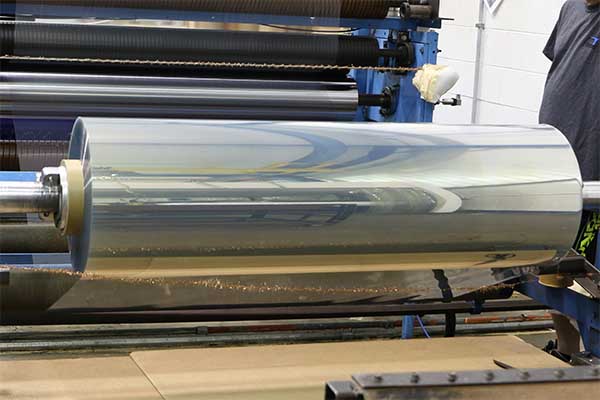

Honyo leverages its integrated Shenzhen manufacturing ecosystem to deliver UV stable sheets with certified performance. Our process begins with vetted raw material suppliers providing pre-stabilized pellets meeting stringent ISO and ASTM weathering standards. In-house extrusion lines utilize precision temperature zoning and calibrated screw speeds to ensure optimal melt homogeneity without thermal breakdown of stabilizers. Critical to quality is our real-time monitoring of sheet thickness uniformity (±0.05mm tolerance) and surface gloss consistency, directly impacting UV resistance uniformity. Post-extrusion, we implement controlled annealing to relieve internal stresses, preventing warpage during subsequent fabrication or outdoor service.

Fabrication of components from UV stable sheets demands specific protocols. Laser cutting parameters are meticulously optimized to minimize heat-affected zones that could compromise the stabilizer system at edges. CNC routing employs sharp tooling and reduced feed rates to avoid micro-fractures. Crucially, all secondary operations are validated through accelerated QUV weathering tests per ASTM G154, simulating years of solar exposure in weeks. This ensures fabricated parts maintain specified optical and mechanical properties throughout their design life.

Key performance characteristics of our standard UV stable sheet offerings are summarized below:

| Material Type | Typical UV Stability Duration | Thickness Range (mm) | Key Applications |

|—————|——————————-|———————|——————|

| Polycarbonate (PC) | 8-10 years | 1.0 – 10.0 | Machine guards, skylights, bus shelters |

| Acrylic (PMMA) | 10+ years | 1.5 – 25.0 | Signage, display cases, lighting diffusers |

| PETG | 5-7 years | 0.5 – 6.0 | Point-of-purchase displays, protective barriers |

Shenzhen Honyo Prototype provides end-to-end capability from stabilized sheet sourcing through precision fabrication and validation testing. Our engineering team collaborates with clients to select the optimal material grade based on geographic UV index, required lifespan, and mechanical loads. By controlling the entire process chain—from additive integration to final part inspection—we ensure UV stable plastic components meet the rigorous demands of outdoor deployment, minimizing field failures and lifecycle costs for your application. Partner with us to transform material science into durable, high-performance products.

Technical Capabilities

Technical Capabilities: UV Stable Plastic Sheet Processing

Shenzhen Honyo Prototype offers advanced manufacturing services for UV stable plastic sheets, engineered to meet the demanding requirements of outdoor and high-exposure applications. Our expertise in laser cutting, bending, and welding ensures precision, durability, and consistent performance across a range of industrial, architectural, and transportation sectors. UV stable plastic sheets are formulated to resist degradation from prolonged ultraviolet radiation, maintaining structural integrity, color fidelity, and surface finish under harsh environmental conditions.

Our laser cutting process utilizes high-precision CO₂ laser systems capable of achieving clean, burr-free edges with minimal thermal distortion. This method supports intricate geometries and tight tolerances, making it ideal for prototyping and low-to-mid volume production. The UV resistance of the base material ensures that cut edges do not degrade during or after processing, preserving long-term performance.

Bending of UV stable plastic sheets is performed using digitally controlled heating elements and precision forming tools. This allows for consistent bend angles and radii across batches. We support both free bending and die-assisted forming, with customizable parameters to match project-specific requirements. The thermal stability of UV resistant plastics ensures uniform heating and reduces the risk of cracking or warping during the bending process.

Welding is executed using advanced techniques such as hot gas welding and ultrasonic welding, depending on material type and joint design. These methods produce strong, hermetic seals with mechanical strength approaching that of the base material. All welding procedures are performed by certified technicians following strict quality control protocols to ensure repeatability and reliability in outdoor environments.

We process a range of UV stabilized thermoplastics, including acrylic (PMMA), polycarbonate (PC), and copolyester (PETG), each selected for its balance of optical clarity, impact resistance, and weatherability. All materials are sourced from reputable suppliers and undergo incoming inspection to verify UV stabilization content and compliance with relevant standards.

The following table outlines key material options and achievable tolerances for each fabrication process:

| Material | Thickness Range (mm) | Laser Cutting Tolerance (±mm) | Bending Tolerance (±°) | Welding Joint Strength (% of Base Material) |

|———|————————|——————————-|————————-|———————————————|

| UV-Stable Acrylic (PMMA) | 2.0 – 20.0 | 0.1 | ±1.0 | 85 – 90 |

| UV-Stable Polycarbonate (PC) | 2.0 – 15.0 | 0.15 | ±1.5 | 80 – 85 |

| UV-Stable Copolyester (PETG) | 2.0 – 12.0 | 0.1 | ±1.0 | 88 – 92 |

All fabricated components undergo final inspection for dimensional accuracy, edge quality, and weld integrity. Secondary operations such as polishing, drilling, and surface finishing are available upon request. Shenzhen Honyo Prototype is committed to delivering UV stable plastic sheet solutions that combine technical precision with long-term environmental resilience.

From CAD to Part: The Process

Shenzhen Honyo Prototype: Manufacturing Guide – UV Stable Plastic Sheet Production Process

This section details the standardized workflow for producing components from UV stable plastic sheet materials at Shenzhen Honyo Prototype. While Honyo excels in sheet metal fabrication, we possess complementary capabilities for engineered plastic sheet processing, specifically addressing the stringent requirements of UV stability for outdoor applications. Our integrated process ensures material integrity and part performance from initial inquiry through final delivery.

The workflow initiates with the AI-Powered Quotation System. Upon receiving a CAD model (STEP, IGES, or native formats preferred) and project specifications, our proprietary AI engine performs rapid material and process analysis. It cross-references the geometry against our validated database of UV-stabilized polymers (e.g., polycarbonate, acrylic, ABS grades with certified UV inhibitors), automatically calculating material consumption, estimating machine time for forming/cutting, and factoring in critical environmental exposure parameters. This generates a technically accurate, data-driven quote within hours, highlighting any initial feasibility flags related to UV performance requirements, such as minimum wall thickness for long-term weatherability or complex geometries prone to stress concentration under thermal cycling.

Following quote acceptance, the project enters the Critical Design for Manufacturability (DFM) Review. Our senior engineers conduct a rigorous, multi-point DFM analysis focused explicitly on UV stability implications. We scrutinize wall thickness uniformity to prevent warpage during thermoforming and ensure consistent UV inhibitor distribution. Draft angles are verified to facilitate clean demolding without surface stress that could accelerate UV degradation. We assess hole placement and boss design to minimize stress risers vulnerable to environmental stress cracking under UV exposure. Sharp internal corners are flagged for modification, as they are prone to micro-cracking when subjected to UV-induced embrittlement and thermal expansion/contraction cycles. This phase ensures the design not only functions but also achieves its intended service life in sunlight.

The approved design then moves to Precision Production. Material selection strictly adheres to certified UV-stabilized grades. Primary processes include CNC routing, laser cutting, and thermoforming, all performed under controlled environmental conditions to prevent premature UV exposure during handling. Thermoforming parameters (heat profile, plug assist, cooling rate) are meticulously tuned to the specific sheet grade to avoid surface defects or internal stresses compromising UV resistance. All cut edges are smoothed and free of micro-fractures. Crucially, for applications demanding maximum longevity, we apply specialized post-forming UV-protective coatings where specified, using our in-house dip or spray systems with precise thickness control and curing protocols. Final parts undergo dimensional verification and visual inspection against UV degradation criteria before packaging in UV-blocking materials.

Material performance is foundational. The table below outlines key specifications for common UV-stable sheet materials processed at Honyo:

| Material Property | Polycarbonate (UV Stabilized) | Acrylic (UV Filtered) | ABS (UV Resistant Grade) |

| :————————- | :—————————- | :——————– | :———————– |

| Typical Thickness Range | 1.5 mm – 12.7 mm | 1.6 mm – 25.4 mm | 1.0 mm – 6.0 mm |

| Max Recommended Part Size | 2000 mm x 1200 mm | 3050 mm x 2030 mm | 1500 mm x 1000 mm |

| Key Process for Complex Shapes | Thermoforming | Thermoforming / CNC | Thermoforming / Vacuum Forming |

| Critical UV Stability Note | Requires co-extruded layer; avoid aggressive solvents | Inherently stable; superior clarity retention | Requires specific UV additive package; check chemical resistance |

This structured workflow, combining AI-driven efficiency with deep engineering expertise in material science and plastic fabrication, ensures Honyo Prototype delivers UV-stable plastic sheet components that meet both dimensional precision and long-term environmental performance requirements for demanding outdoor applications.

Start Your Project

Start Your Project with UV Stable Plastic Sheets from Shenzhen Honyo Prototype

When engineering durable, high-performance components for outdoor or high-exposure environments, material selection is critical. At Shenzhen Honyo Prototype, we specialize in precision sheet metal fabrication and advanced material processing, including UV stable plastic sheets designed to withstand prolonged exposure to sunlight, extreme temperatures, and environmental stressors. Whether your application involves signage, protective enclosures, automotive components, or architectural elements, our UV resistant plastic sheet solutions offer long-term reliability without degradation in appearance or mechanical integrity.

UV stable plastic sheets are formulated with special additives that inhibit photodegradation caused by ultraviolet radiation. These materials retain color, tensile strength, and surface finish over extended periods, making them ideal for outdoor use where aesthetics and functionality must endure. Common polymers used include UV-stabilized polycarbonate, acrylic (PMMA), and ABS blends, each offering distinct advantages in impact resistance, clarity, and formability. At Honyo Prototype, we support custom fabrication processes such as laser cutting, CNC routing, bending, and precision drilling to deliver finished parts that meet exact design specifications.

Our manufacturing capabilities are backed by rigorous quality control and rapid prototyping services, enabling clients to move efficiently from concept to production. We understand that every project has unique requirements—whether it’s tight tolerances, specific finish treatments, or compliance with industry standards—and our engineering team works closely with clients to ensure optimal material and process selection.

To help you make an informed decision, the following table outlines key properties of commonly used UV stable plastic sheets:

| Material | UV Resistance | Tensile Strength (MPa) | Light Transmission (%) | Common Applications |

|——–|—————-|————————|————————|———————-|

| UV-Stabilized Polycarbonate | Excellent | 60–70 | 88–90 | Safety glazing, machine guards, automotive lenses |

| UV-Grade Acrylic (PMMA) | Very Good | 70–75 | 92–93 | Signage, displays, architectural panels |

| UV-Resistant ABS | Good | 40–50 | Opaque | Enclosures, automotive trims, industrial housings |

| Polystyrene (HIPS, UV modified) | Moderate | 30–35 | Opaque to translucent | Point-of-purchase displays, light diffusers |

All materials are sourced from certified suppliers and undergo in-house testing to verify UV performance under simulated weathering conditions. We also offer accelerated aging reports upon request to support product validation.

Starting your project with Shenzhen Honyo Prototype is simple. Share your design files, material preferences, and production goals with our team, and we’ll provide technical feedback, a detailed quote, and lead time estimates within 24 hours. Our streamlined workflow supports low-volume prototyping and high-volume production runs with consistent quality and on-time delivery.

For immediate assistance, contact Susan Leo at info@hy-proto.com. She will guide you through the onboarding process, answer technical inquiries, and help optimize your design for manufacturability. At Honyo Prototype, we’re committed to being your trusted partner in precision fabrication—where innovation meets durability.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.